INCRA TS-III ULTRA Shopsmith Owner’s Manual 13

can micro adjust a full 1/4” in either direction.

The scale is marked in 1/32” increments.

IMPORTANT: Do not turn the micro adjusting

knob with the carriage clamp in the “locked”

position. The carriage clamp must always

be “unlocked” and the micro adjust lever

pushed down before micro adjusting the

fence position.

All of the components and features of you

new INCRA TS-III Ultra have been factory set

and should require no further adjustment. If

however, you wish to adjust or recalibrate

these components the following information

is provided to assist in performing the

adjustments.

Adjusting the clamping pressure

Note: The Ultra base must be attached to

the base support panel with all six mounting

screws tightened before adjusting the

clamping pressure.

The Ultra base and carriage clamp were

designed to make it easy for the operator to

adjust the clamping pressure to his individual

preference using the supplied clamp pad

shims. Hereʼs how:

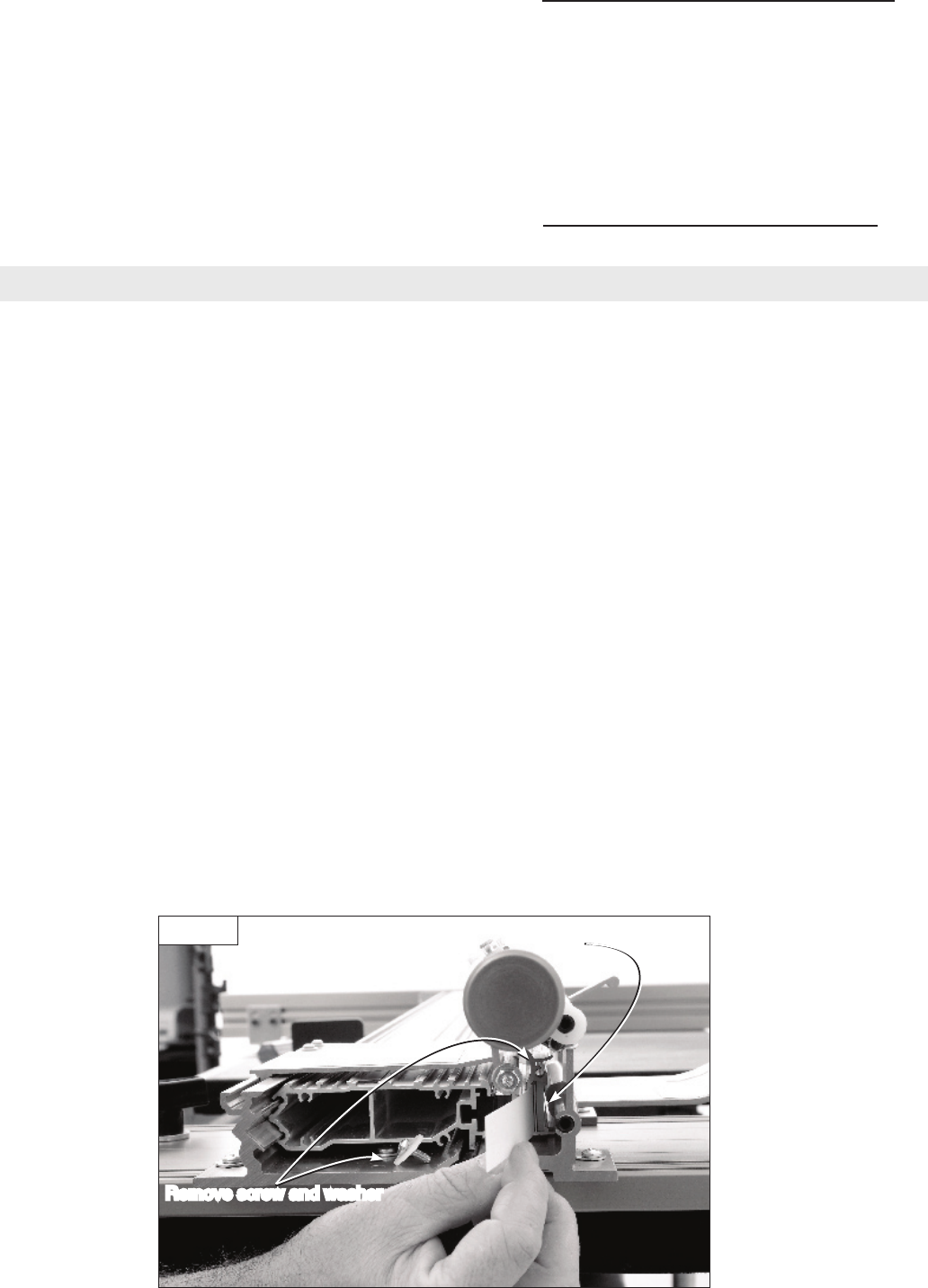

“Unlock” the carriage clamp, slide the carriage

so that its end is about 1” forward of the rear

of the Ultra base and press the micro adjust

lever down. Remove the Phillips head screw

and nylon washer that caps the end of the

clamping pad slot. Your hardware pack

for the INCRA TS-III Ultra includes (3) 6” x

7/8” x .005” clamp pad shims. If you want

to increase the clamping pressure add one

of these shims to the front of the clamping

pad slot. Check the clamping pressure, and

adjust further as necessary. The shim should

be placed to the left (inside) of the 1/8” thick

clamp pad shown in Fig. 29. To decrease

the clamping pressure just remove one of the

thin shims already in place. When you are

satisfied with the clamping pressure replace

the Phillips head screw and nylon washer.

Caution: If you have reduced clamping

pressure by removing a shim, be certain

that adequate pressure remains to hold the

carriage rigidly in place when clamped in

the fully extended position. If not, increase

clamping pressure by adding shims as

described above.

ADJUSTMENTS

TIP

▼▼▼▼▼▼▼▼▼▼▼

At the end of each day, you might

want to micro adjust back to mid-

range on the range scale. This

ensures that youʼll have plenty

of micro adjusting range the next

time you begin a project.

▲▲▲▲▲▲▲▲▲▲▲TIP

Figure 29

To change clamping pressure, add or remove

shims to the left of 1/8” thick clamping pad

Remove screw and washer