30.

Adjustments

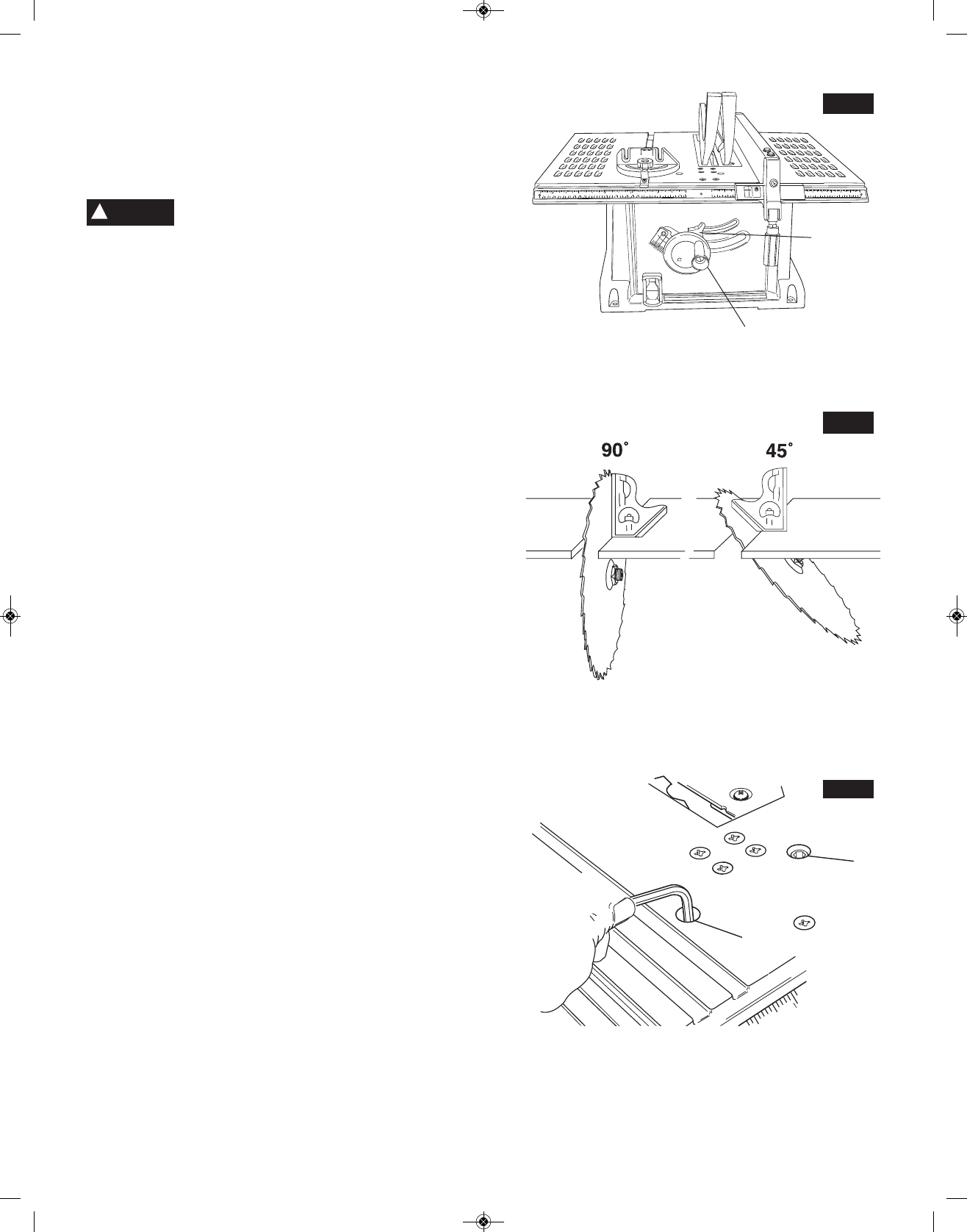

90° and 45° Positive Stops

Adjustment

To prevent personal injury, always dis con nect the

plug from power source before mak ing any

adjustments.

The saw has positive stops that will quickly position the saw blade

at 90° or 45° to the table. Make the following adjustments only if

necessary.

NOTE: 90° and 45° blade adjustment screws require a 5 mm Allen

wrench (not supplied) and a 10 mm wrench or socket (not

s

upplied) for adjustment. To access the 10 mm jam nut attached to

the 90° and 45° adjustment screws, turn the saw on its left side.

Make sure the saw is secure.

Adjusting the 90° Stop:

1. Raise the blade to the maximum height by turning the control

wheel 1 counterclockwise (Fig. 7).

2. Loosen the blade lock knob 2. Push in the blade

elevation/tilting control wheel 1 and rotate clockwise as far as

possible (Fig. 7).

3. Place a combination square on the table and against the

blade to determine if the blade is at a 90° angle to the table

(Fig. 8).

4. If the blade is not at a 90° angle to the table, loosen the jam nut

(underneath table) and turn the 90° adjusting socket head screw

3 (Fig. 9) left to reduce the angle or right to increase the angle.

Adjusting the 45° Stop:

1. Raise the blade to the maximum height by turning the control

wheel 1 counterclockwise (Fig. 7).

2. Loosen the blade lock knob 2. Push in the blade elevation/tilting

control wheel 1 and rotate counterclockwise as far as possible

(Fig. 7).

3. Place a combination square on the table and against the

blade to determine if the blade is at a 45° angle to the table

(Fig. 8).

4. If the blade is not at a 45° angle to the table, loosen the jam nut

(underneath table) turn the 45° adjusting socket head screw 4 left

to reduce the angle or right to increase the angle (Fig. 9).

Adjusting the Blade Tilt Indicator:

1. When the blade is positioned at 90°, adjust the blade tilt

pointer to read 0° on the scale.

2. Loosen the holding screw, position pointer over 0° and tighten

the screw.

NOTE: Always make a trial cut on scrap wood when making critical

cuts. Measure for cut precision.

FIG. 8

1

2

FIG. 7

3

4

FIG. 9

WARNING

!

SM 2610008289 02-10:3310 Table Saw 2/2/10 8:38 AM Page 30