-32-

For Machines Mfg. Since 8/09

Model SB1029

OPERATION

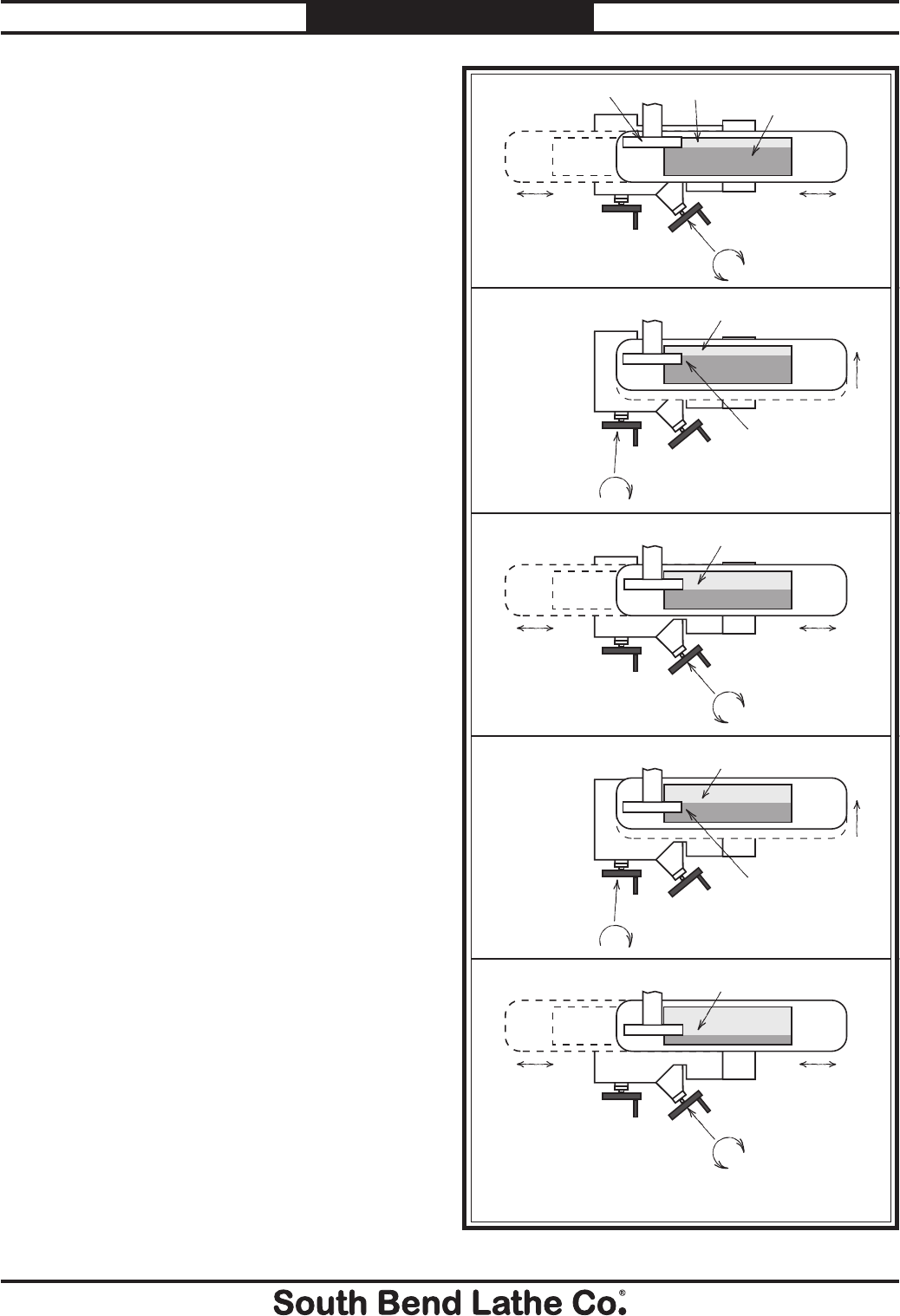

Figure 43. Grinding process illustrated.

Workpiece

Surfaced Portion

Grinding Wheel

Surfaced Portion

Surfaced Portion

New Portion

Exposed

*Movement exaggerated for clarity

*Movement exaggerated for clarity

Continue/repeat as necessary until desired

results are achieved.

Surfaced Portion

New Portion

Exposed

Surfaced Portion

Using the Surface Grinder

Operation of the grinder is controlled through

the movement of the three handwheels. The

elevation handwheel controls the up and down

movement of the grinding head. It is this axis

that governs the amount of stock removal. Never

attempt to remove too much material in one

pass. The best results are achieved with multiple

light passes.

The longitudinal travel handwheel rapidly moves

the table from left to right. This allows the

operator to move the workpiece back and forth

underneath the grinding wheel.

The cross travel handwheel controls the front-

to-back movement of the table and is only to be

used between longitudinal passes to expose a

new area of the workpiece to the grinding wheel.

Slightly overlap passes to ensure complete

coverage.

When grinding, sweep the table back and forth

under the wheel in the longitudinal direction

until no further sparks emerge from the

workpiece, move the table in the cross direction

to expose a new portion of the workpiece to

the wheel, then take another sweep in the

longitudinal direction. Repeat this process until

the entire surface is ground. See Figure 43 for

an illustration of this process.

Grinding Tips

While every grinding operation is unique, there

are a few techniques that apply to most, if not all

grinding operations.

s $URINGLONGITUDINALPASSESTIGHTENTHECROSS

travel lock knob to prevent chatter that may

occur as a result of slight cross movement of

the table.

s "ETWEENLONGITUDINALPASSESUSETHE

squeegee to remove any foreign material

from the workpiece.

s !FTERANINITIALPASSADJUSTTHEDUSTPORT

to be directly in the path of the sparks to

minimize the amount of waste material

ejected into the work space.