service

-38-

For Machines Mfg. Since 8/09

Model SB1029

SERVICE

Machine Storage

If the machine is not properly prepared for

storage, it may develop rust or corrosion. If

decommissioning this machine, use the steps

in this section to ensure that it remains in good

condition for later use.

To prepare your machine for storage:

1. Pump out the old oil, then clean and wipe

out the oil reservoir.

2. If coolant was used, put on safety goggles

and clean the coolant system. Next, add

a few drops of oil in the lines to prevent

corrosion, and blow out the lines with

compressed air.

3. DISCONNECT MACHINE FROM POWER!

4. Remove the grinding wheel and hub. Coat

the hub tapered bore and the spindle taper

with white lithium grease for protection.

5. Lubricate the machine as outlined in the

Maintenance Schedule on Page 32, and

thoroughly clean all unpainted bare metal

surfaces, then apply a liberal coat of way oil.

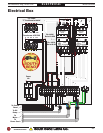

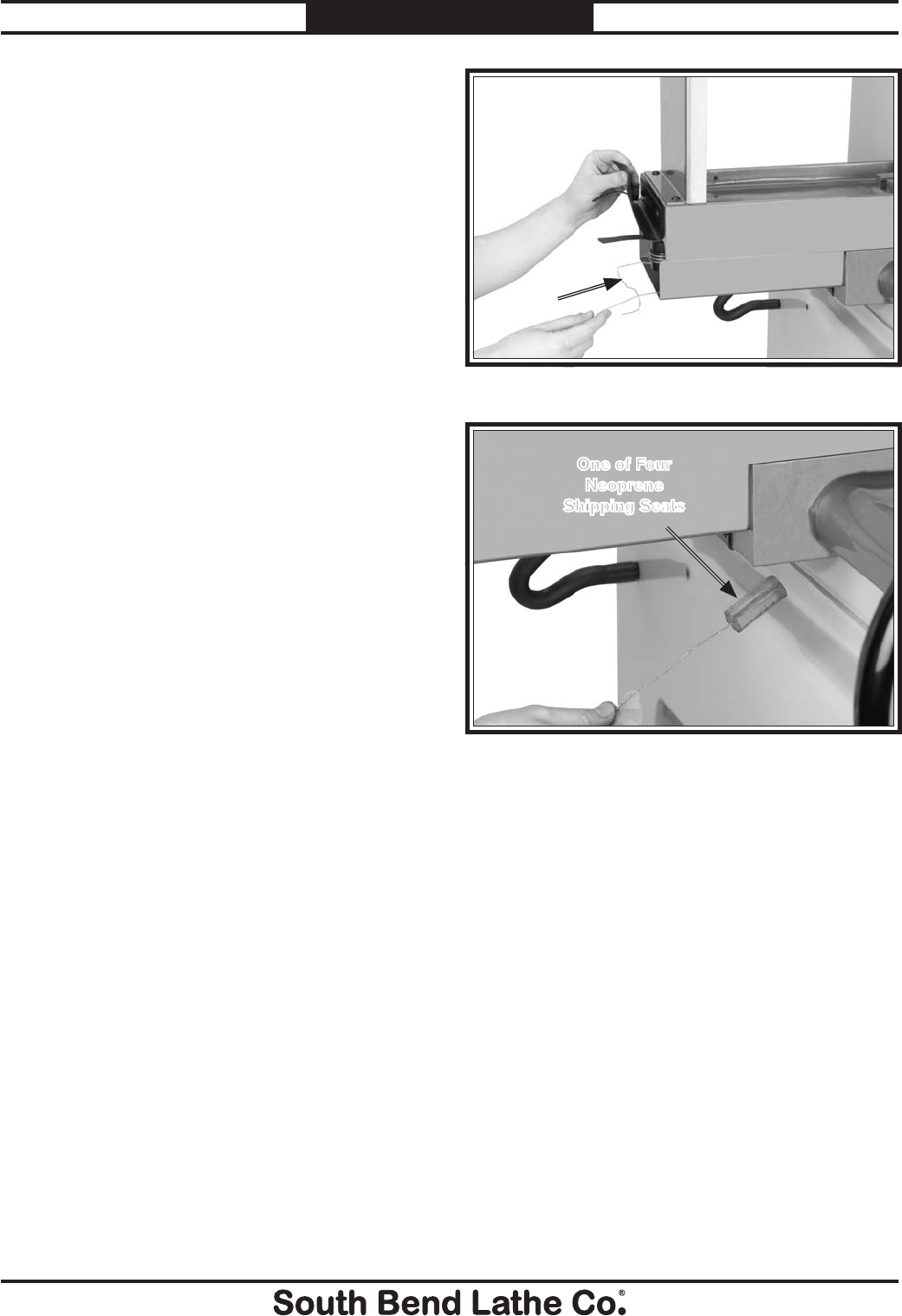

6. Have an assistant carefully lift up on the

table so it is raised approximately an inch or

two, use the wires to insert each neoprene

seat into its respective way (see Figures 50

–51), then carefully lower the table onto the

ball bearings. The table must be resting on

the seats at all four corners.

Figure 50. Neoprene shipping seat wires.

Wires

Figure 51. Neoprene shipping seat.

One of Four

Neoprene

Shipping Seats

7. Next use a paint brush and white lithium

grease to coat all bearings and ways with a

coat of grease to prevent rust.

8. Place one or two moisture absorbing

desiccant bags at the bottom of the electrical

box.

9. Cover and place the machine in a dry area

that is out of direct sunlight and away from

hazardous fumes, paint, solvents, or gas.

Fumes and sunlight can bleach or discolor

paint and make plastic guards cloudy.