For Machines Mfg. Since 8/09 Model SB1029

-41-

ELECTRICAL

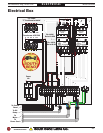

3. Without changing the location of any of the

wires, reposition the jumpers as shown in

Figure 54. Stack the jumpers as needed,

since there will be two extras.

Figure 54. 440V Jumper locations.

GND

U

1

2

3

4 5 6

V W

Motor

7

8

9

Jumpers

4. Tighten the nine screws that secure the

wires and jumpers, making sure the wires

are still located in their original positions.

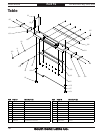

5. Open the electrical box on the side of the

machine. Loosen all of the screws that secure

the wires to the thermal relays and the

screws that secure the thermal relays to the

contactors (Figure 55). Pay careful attention

to the location of the wires so you can replace

them in the same position later.

Figure 55. 220V Thermal relays.

AMP

THERMAL

RELAY

CONTACTOR

Allen Bradley

C09400

1357L1 L2 L3 L4

2468T1 T2 T3 T4

95 96 NONC 97 98

AMP

AB 193 TAB60

AB 193 TAB24

THERMAL

RELAY

CONTACTOR

Allen Bradley

C09400

1357L1 L2 L3 L4

2468T1 T2 T3 T4

95

4

5

6

1.6 2.4

96 NONC 97 98

8

9

OO

U V W

W1

V1

U1

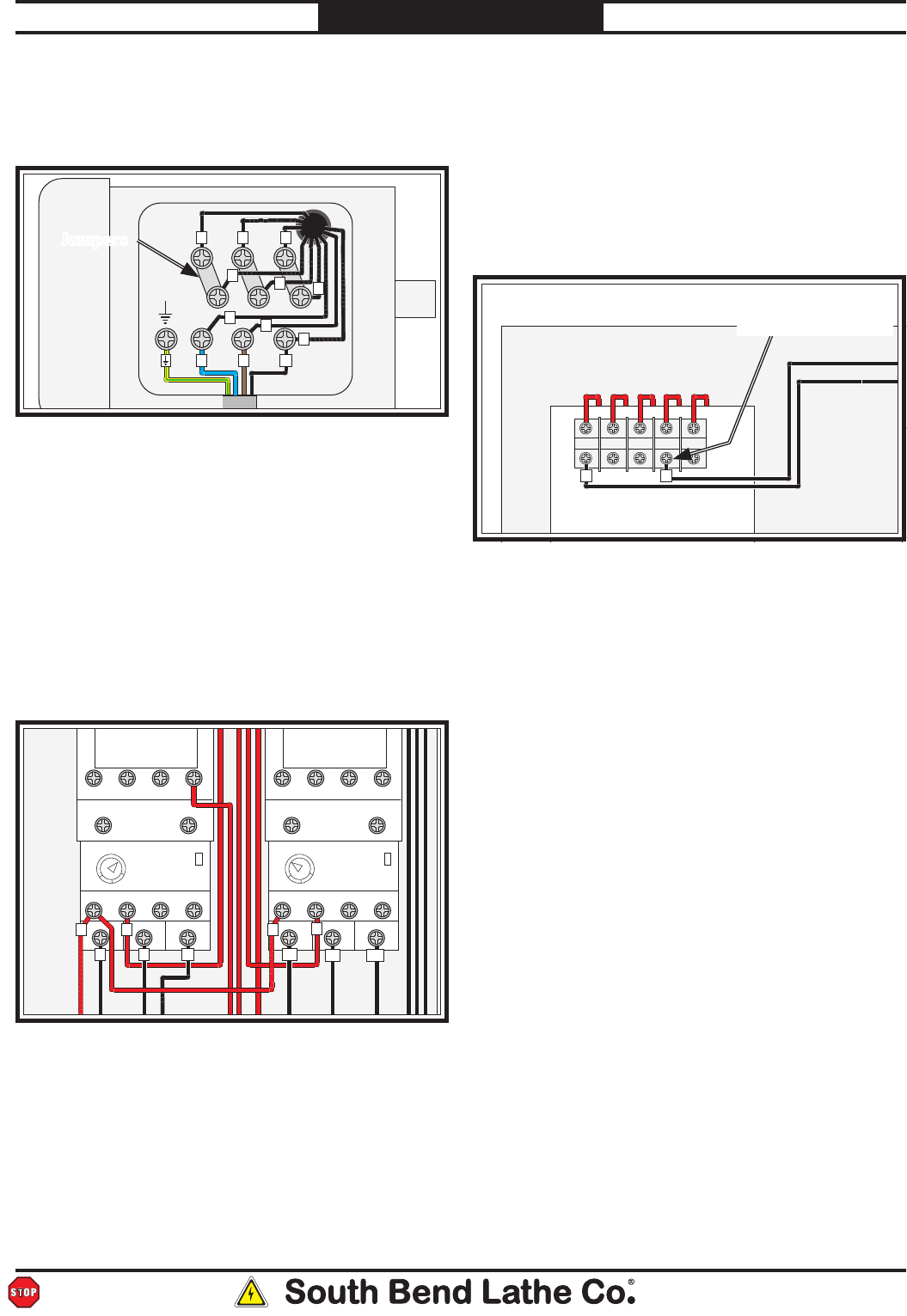

Figure 56. Wire "T" moved to 440V.

12345

R T

Transformer LCP-TBS

For 440V:

Set at 0.25A

For 440V:

"T" Positioned at 440V

012240110

0 208 220 440 480

Wire "T" moved to

440V Terminal

6. Replace the installed relays for the coolant

pump relay and spindle motor with the

relays from the 440V conversion kit,

installing all of the wires in the same

location from which they were removed.

7. Move the "T" wire from the 220V terminal

to the 440V terminal on the transformer, as

shown in Figure 56.

8. Hardwire the machine to a 440V locking

disconnect switch.

READ ELECTRICAL SAFETY

ON PAGE 39 FIRST!