-54-

For Machines Mfg. Since 8/09

Model SB1029

PARTS

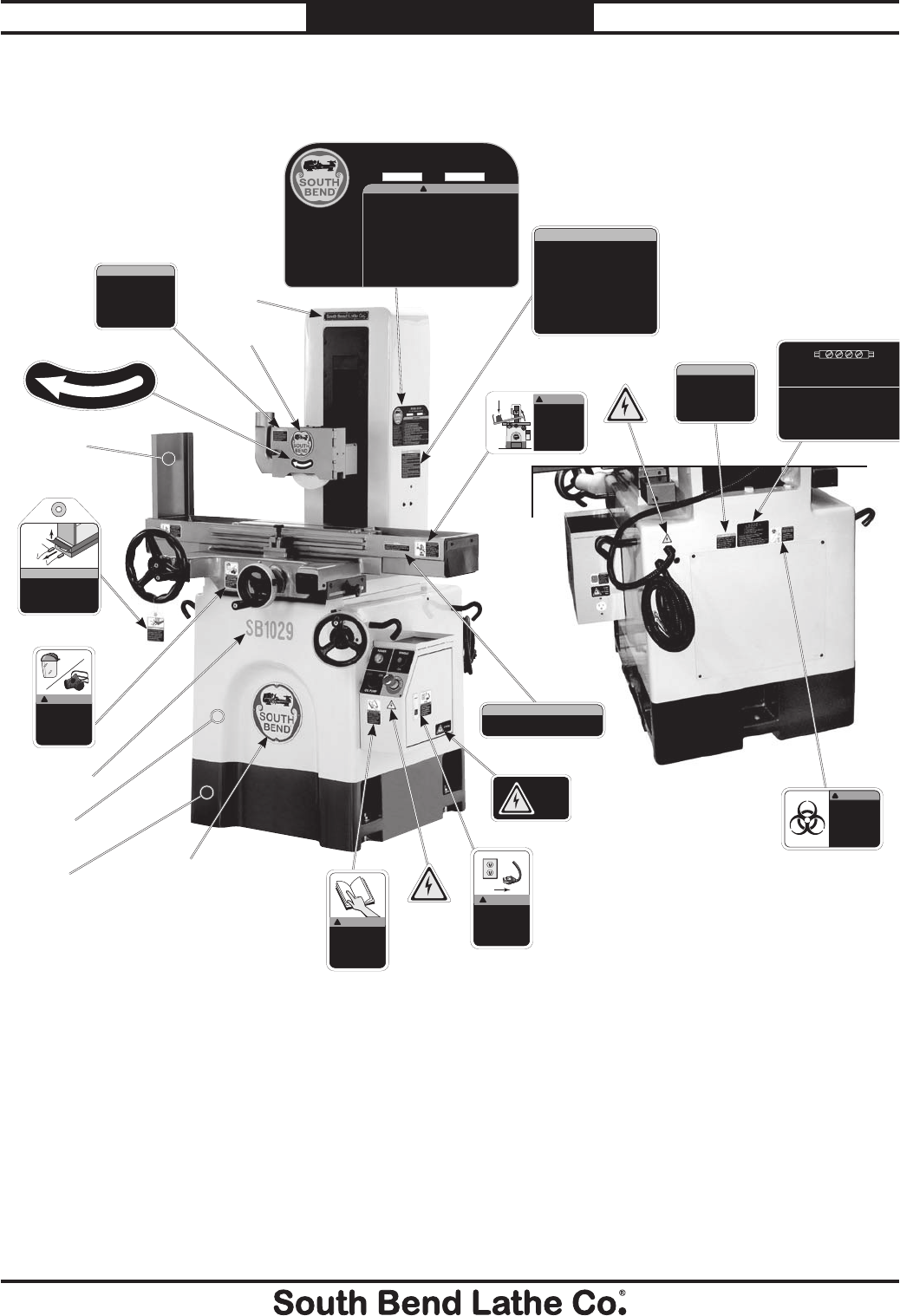

Machine Labels

Made in Taiwan to South Bend Specifications

TO REDUCE THE RISK OF SERIOUS PERSONAL INJURY WHILE USING THIS

MACHINE:

WARNING!

!

MODEL SB1029

6" x 18" SURFACE GRINDER

MFG Date:Serial No:

1. Read and understand manual before starting.

2. Always wear eye protection and respirator.

3. Always balance and dress wheel before use.

4. Never place hands near moving machine parts or workpiece.

5. Never use hands to hold workpiece while grinding.

6. Inspect wheel before each use. Never use grinding wheels that have been

dropped or have chips or cracks. Inspect wheel before each use.

7. Do not wear loose clothing, gloves or jewelry. Secure long hair and button all

long sleeve shirts.

8. Disconnect power before servicing, setting up or adjusting.

9. Do not use grinding wheels rated lower than 3450 RPM.

10. Do not operate under the influence of drugs or alcohol.

11. Make sure machine is properly adjusted, set up, and workpiece is clamped

before starting motor.

12. Keep floor area around the grinder clean and dry.

13. Never leave the machine running unattended.

Motor: 1-1/2 HP, 220V/440V, 3-Phase

Table Surface Size: 5-3/4" X 18"

Spindle Speed: 3450 RPM

Longitudinal Travel: 18-7/8"

Cross Travel: 6-15/16"

Max. Distance Wheel To Table: 15.3"

Maximum Grinding Length: 18-1/2"

Maximum Grinding Width: 6-15/16"

Ver tical Handwheel Revolution: 0.05"

Crossfeed Handwheel Revolution: 0.2"

Grinding Wheel: 7"D X 1/2"W X 1-1/4"B

Spindle Arbor: 1"D X 7.5° Taper

Floor to Table Height: 40"

Weight: 1672 Lbs.

WARNING!

!

POISON/

BIOHAZARD

Refer to the cutting

fluid manufacturer’s

Material Safety Data

Sheets (MSDS) for

safety information.

WARNING!

!

!

INJURY/SHOCK

HAZARD

To avoid shock or

accidental starting,

disconnect power

before adjusting or

servicing machine.

220V

3-Ph

EYE/FACE/LUNG

INJURY HAZARD

Always wear a face

shield and respirator

when using this

equipment.

WARNING!

!

Before using machine, remove

this cover and make sure the

lubrication tank is filled with

Mobil Vacuoline 1405 or

equivalent oil (ISO 32 Way Oil)

to provide lubrication to the

ways.

NOTICE

1234

1. Vertical Leadscrew

2. Cross Leadscrew

3. Longitudinal & Cross Slideways

4. Pressure Discharge

• Turning valve counterclockwise reduces oil flow.

• Turning valve clockwise increases oil flow.

• To restore factory settings:

Valve 1: Turn fully counterclockwise (full flow).

Valves 2 & 3: Turn clockwise until snug, then back

1

turn.

Valve 4: Turn clockwise until snug, then loosen unti

steady drip is observed (about 3 drops per second)

.

If excessive play develops in the longitudinal hand-

wheel, the cable drive can be tightened. See your

Owner’s Manual for details.

NOTICE

NOTICE

TIPS FOR BEST GRINDING RESULTS:

• Make sure the grinding wheel is balanced before use.

• Select an appropriate grinding wheel according to the

workpiece material.

• Keep a thin coat of oil on the spindle nose and wheel

flange to prevent rust.

• Never use compressed air to clean the machine.

Doing so will force metal chips into the table ways.

• Keep longitudinal handwheel drive cable properly

tightened.

• Empty, clean, and refill oil reservoir every 3–6

months.

• Adjust oil flow as necessary to maintain smooth

operation of all moving parts.

• Clean dust collection at least weekly, or any time you

notice a drop in suction.

Before using the machine, lift the

table and remove the four plastic

shipping support blocks from

both ends. Save these blocks for

future transport of the machine.

NOTICE

x4

•

Cle

notice

INJURY HAZARD

Do not use machine if

you have not read the

manual. Visit

southbendlathe.com or

call 360-734-1540 to

get a manual.

WARNING!

!

Only trained and properly

supervised personnel are

allowed to operate this machine.

If safe operation procedures are

not clearly understood, request

additional training from a

supervisor before beginning

operation.

NOTICE

TIPPING HAZARD

DO NOT place a

heavy object at one

end of the table. Doing

so may cause the table

to tip, resulting in

personal injury or

damage to machine.

WARNING!

!

301

302

303

304

305

306

307

310

311

312

313

314

316

317

318

319

320

321

322

323

324

325

326