For Machines Mfg. Since 8/09 Model SB1029

-33-

MAINTENANCE

MAINTENANCE

Maintenance Schedule

Recommended Lubricating Oil Types:

To avoid oil breakdown, DO NOT MIX OILS! If

changing oil types, be sure to flush system with

the new oil and discard the flushed oil.

s Mobil Vacuoline 1405

s Mobil Vacuoline 1409

s Shell Tonna 33

s Shell Tonna 27

s BP Energol HP 20-C

Daily:

s #HECKCORRECTLOOSEMOUNTINGBOLTS

s Check/correct damaged or cracked grinding

wheel.

s Check/correct worn or damaged wires.

s Clean/protect table.

s Vacuum metal shavings from machine.

s Correct any other unsafe condition.

Bi-Annually:

s Change lubrication oil, verify oil distribution

setting.

s Clean and re-oil pinion gears.

Annually:

s Remove pump screen and clean debris.

s Verify machine is level and readjust as

required.

Always disconnect

machine from power before

performing maintenance or

serious personal injury may

result.

!

Basic Lubrication

If this machine is used in a heavy industrial

setting, or in a dirty or damp environment,

increase the oil-change intervals.

If the machine is new or being put back into

service from storage, you must first to flush the

lubrication system with ATF Dextron II. Run the

pump for 5-10 minutes, and move all handwheels

through their full range of motion as the high

detergent oil breaks down and flushes away

storage grease from the bearings, ways, and

galleys. When finished, drain and refill the oil

system, and conduct a test run as outlined in this

manual.

To lubricate your machine:

1. Read and take the appropriate safety

measures covered in this manual.

2. Remove the screws and the left-side cabinet

access plate, and fill the oil reservoir or

replace the oil if it is dirty (see Figure 44).

Figure 44. Lubrication pump and reservoir.

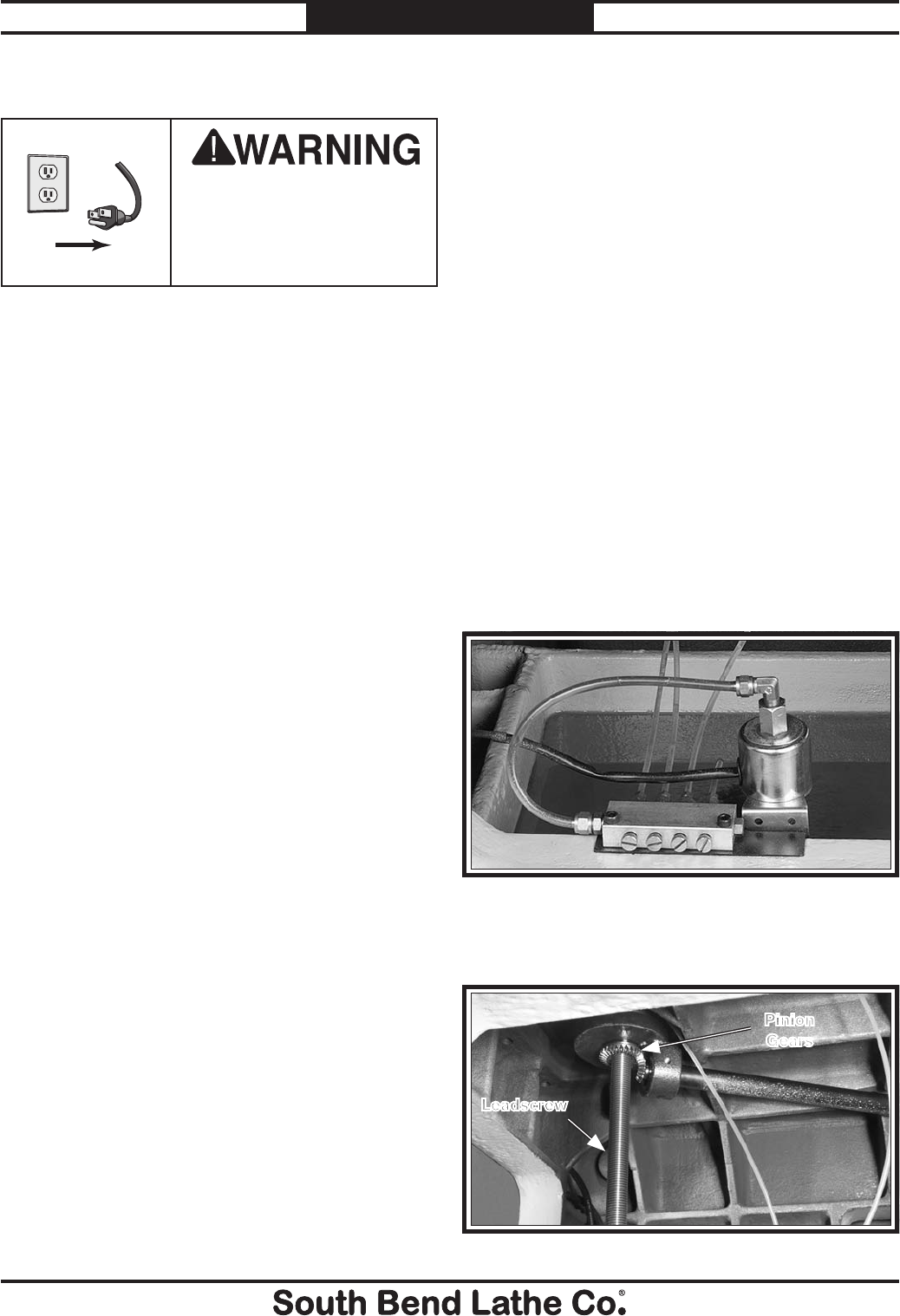

3. Make sure the pinion gears and leadscrew

(Figure 45) are wet with oil.

Figure 45. Lower leadscrew and pinion gears.

Pinion

Gears

Leadscrew