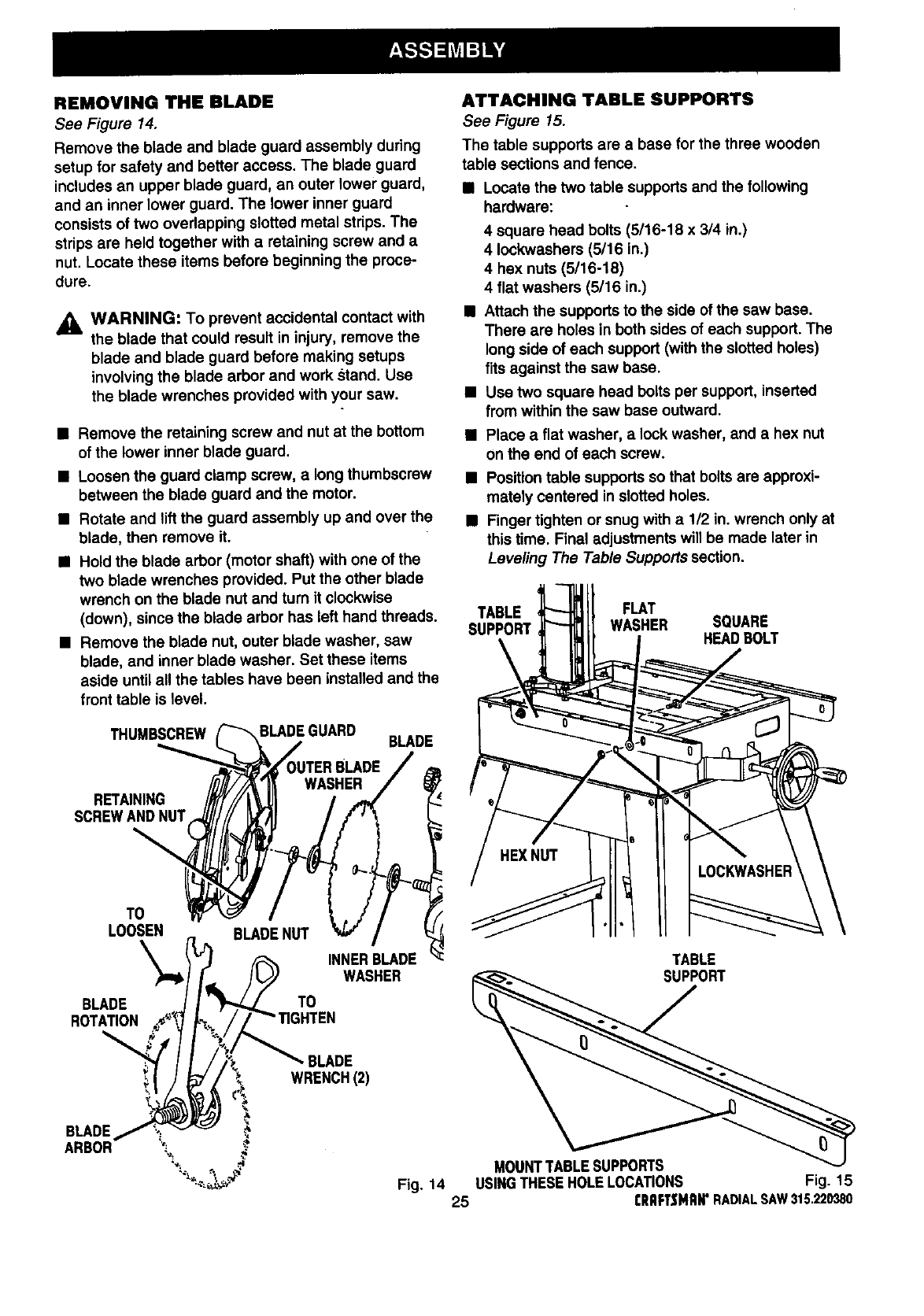

REMOVING THE BLADE

See Figure 14.

Remove the blade and blade guard assembly during

setup for safety and better access. The blade guard

includes an upper blade guard, an outer lower guard,

and an inner lower guard. The lower inner guard

consists of two overlapping slotted metal strips. The

strips are held together with a retaining screw and a

nut. Locate these items before beginning the proce-

dure.

,_ WARNING: To prevent accidental contact with

the blade that could result in injury, remove the

blade and blade guard before making setups

involving the blade arbor and work stand. Use

the blade wrenches provided with your saw.

• Remove the retaining screw and nut at the bottom

of the lower inner blade guard.

• Loosen the guard clamp screw, a long thumbscrew

between the blade guard and the motor.

• Rotate and liftthe guard assembly up and over the

blade, then remove it.

• Hold the blade arbor (motor shaft) with one of the

two blade wrenches provided. Put the other blade

wrench on the blade nut and turn it clockwise

(down), since the blade arbor has left hand threads.

• Remove the blade nut, outer blade washer, saw

blade, and inner blade washer. Set these items

aside until all the tables have been installed and the

front table islevel.

THUMBSCREW

BLADEGUARD

BLADE

RETAINING

SCREWANDNUT

TO

LOOSEN BLADENUT

BLADE

ROTATION

TO

INNERBLADE

WASHER

BLADE

ARBOR

BLADE

WRENCH(2)

ATTACHING TABLE SUPPORTS

See Figure 15.

The table supports are a base for the three wooden

table sections and fence.

• Locate the two table supports and the following

hardware:

4 square head bolts (5/16-18 x 3/4 in.)

4 Icckwashers (5/16 in.)

4 hex nuts (5/16-18)

4 flat washers (5/16 in.)

• Attach the supports to the side of the saw base.

There are holes in both sides of each support. The

long side of each support (with the slotted holes)

fits against the saw base.

• Use two square head bolts per support, inserted

from within the saw base outward.

• Place a flat washer, a lock washer, and a hex nut

on the end of each screw.

• Position table supports so that bolts are approxi-

mately centered in slotted holes.

• Finger tighten or snug with a 1/2 in. wrench only at

this time. Final adjustments will be made later in

Leveling The Table Supports section.

TABLE FLAT

SUPPORT WASHER SQUARE

HEADBOLT

Fig. 14

25

TABLE

USINGTHESEHOLELOCATIONS Fig. 15

CRIII:TJ_MIIN"RADIALSAW315,220380