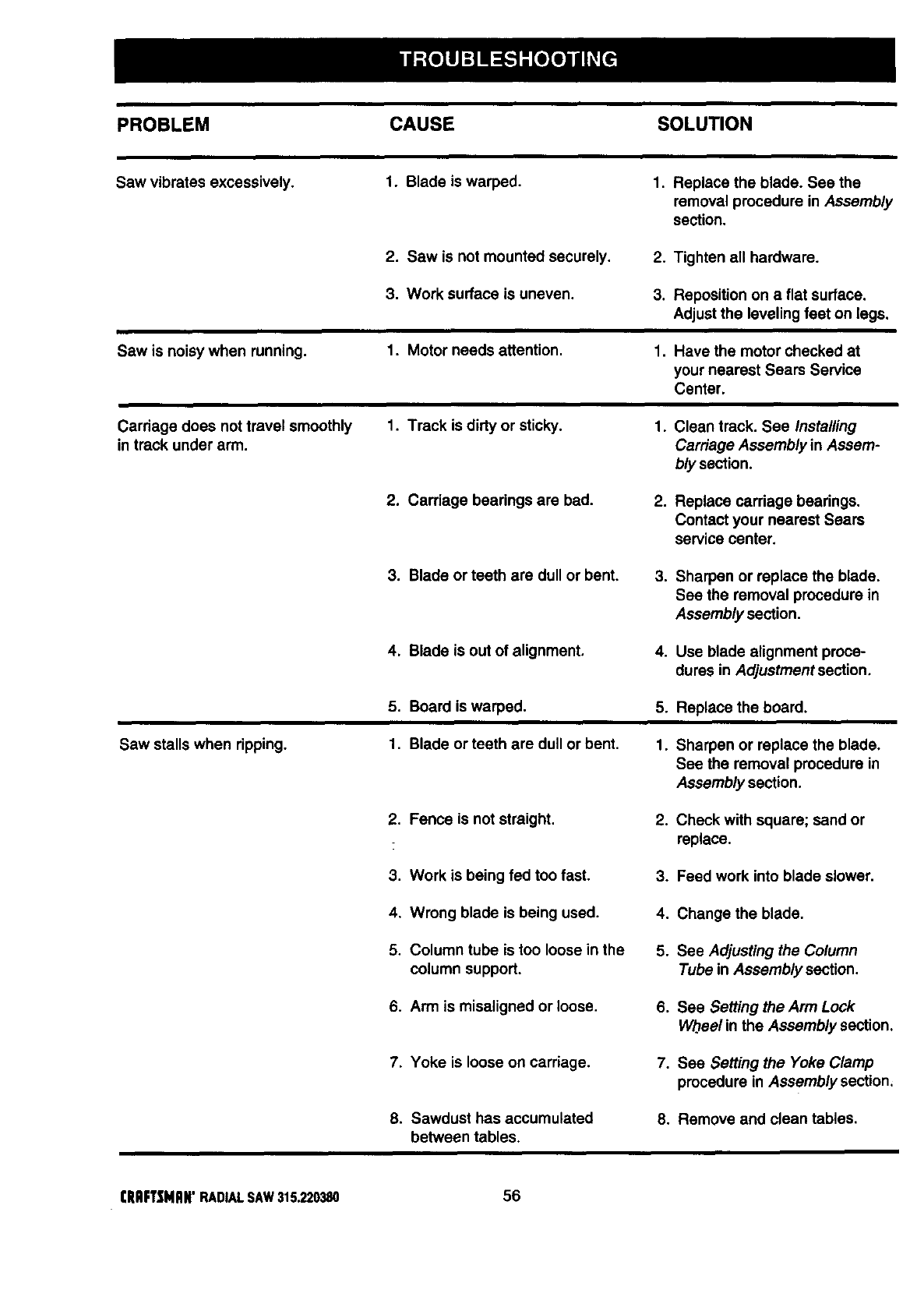

PROBLEM CAUSE SOLUTION

Saw vibrates excessively. 1. Blade is warped. 1. Replace the blade. See the

removal procedure in Assembly

section.

2. Saw is not mounted securely. 2. Tighten all hardware.

3. Work surface is uneven. 3. Reposition on a flat surface.

Adjust the leveling feet on legs.

Saw is noisy when running. 1. Motor needs attention. 1. Have the motor checked at

your nearest Sears Service

Center.

Cardage does not travel smoothly 1. Track is dirty or sticky. 1. Clean track. See Installing

in track under arm. Carriage Assembly in Assam-

bly section.

2. Carriage bearings are bad.

2. Replace cardage bearings.

Contact your nearest Sears

service center.

3. Blade or teeth are dull or bent.

3. Sharpen or replace the blade.

See the removal procedure in

Assembly section.

4. Blade is out of alignment.

4. Use blade alignment proce-

dures in Adjustment section.

5. Board is warped.

5. Replace the board.

Saw stalls when ripping.

1. Blade or teeth are dull or bent.

1. Sharpen or replace the blade,

See the removal procedure in

Assembly section.

2. Fence is not straight, 2. Check with square; sand or

: replace.

3. Work is being fed too fast.

3. Feed work into blade slower.

4. Wrong blade is being used. 4. Change the blade.

5. Column tube is too loose in the

column support.

5. See Adjusting the Column

Tube in Assembly section.

6. Arm is misalJgned or loose. 6. See Setting the Arm Lock

Wl_eel in the Assembly section.

7. Yoke is loose on carriage. 7. See Setting the Yoke Clamp

procedure in Assembly section,

8. Sawdust has accumulated

between tables.

8. Remove and clean tables.

CRIIFTSHFIN'RADIALSAW315.220380 56