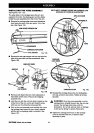

SETTING THE ARM LOCK KNOB

See Figure 16.

It may be possible to move the arm when locked, if

the arm lock knob is too loose. If the arm does not

move freely when unlocked, the arm lock knob may

be too tight. Use this procedure to chec.k and set the

arm lock knob by turning the arm lock wheel (under

the carriage arm).

• Release the arm lock knob, located on top of the

arm at the front.

• Swing the arm 30" to the left or the right, referring

to the miter scale on top ofthe column.

• Lock the arm in place with the arm lock knob.

• Apply a reasonable amount of pressure. The arm

can be forced but if it moves easily, it needs

adjustment.

• Locate the arm lock wheel.

• Release the arm lock knob and turn the lock wheel

clockwise to tighten or counterclockwise to loosen.

• Repeat above steps untilthe arm movement is

minimized when locked.

ARM LOCK KNOB ARM

TURNCOUNTERCLOCK-

WISETOLOOSEN

CARRIAGE TURNCLOCKWISE

STOPSCREW ARM TO TIGHTEN

LOCKWHEEL Fig. 16

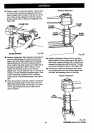

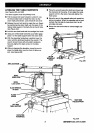

SETTING THE YOKE CLAMP

See Figures 17A and 17B.

The yoke clamp keeps the yoke from rotating on the

carriage when you want the saw blade to be station-

ary. Use this procedure to check and set the yoke

clamp.

• Release the yoke lock handle (below the arm on

the right side) so the motor can be rotated.

• Swivel the motor slightly. It should be at an angle in

between one of the preset positive stop angles.

ARMCAP MOTOR

YOKELOCK

HANDLE

YOKE

ASSEMBLY Fig. 17A

• Lock the yoke lock handle. Grasp the motor with

both hands and apply reasonable pressure to see if

it slips. If it moves, reset the yoke lock handle as

follows.

• Remove the arm cap screws and arm cap at the

front of the arm with a phillips screwdriver. See

Figure 13B.

• Remove the carriage stop screw and Iockwasher

with a 1/4 in. hex key. Carefully slide the yoke

assembly forward and off the carriage.

• Place the yoke assembly in a spot where it will be

secure as you work on the top of the yoke,

• Release the yoke lock handle. Tighten the center

nut with a 15/16 in. wrench until the lock handle is

centered between the two legs of the yoke.

• Carefully replace the yoke assembly on the car-

riage arm track. Slide it back about halfway.

• Replace the cardage stop screw and Iockwasher,

followed by the arm cap and arm cap screws.

• Lock and test the yoke again. If it can be moved,

repeat the procedure until it is secure.

I_I_CENTER NUT

YOKELOCK

HANDLE

LEG

Fig. 17B

[RAFTSMAN"RADIALSAW315.220380 26