G0504 16" Horizontal Resaw Bandsaw -21-

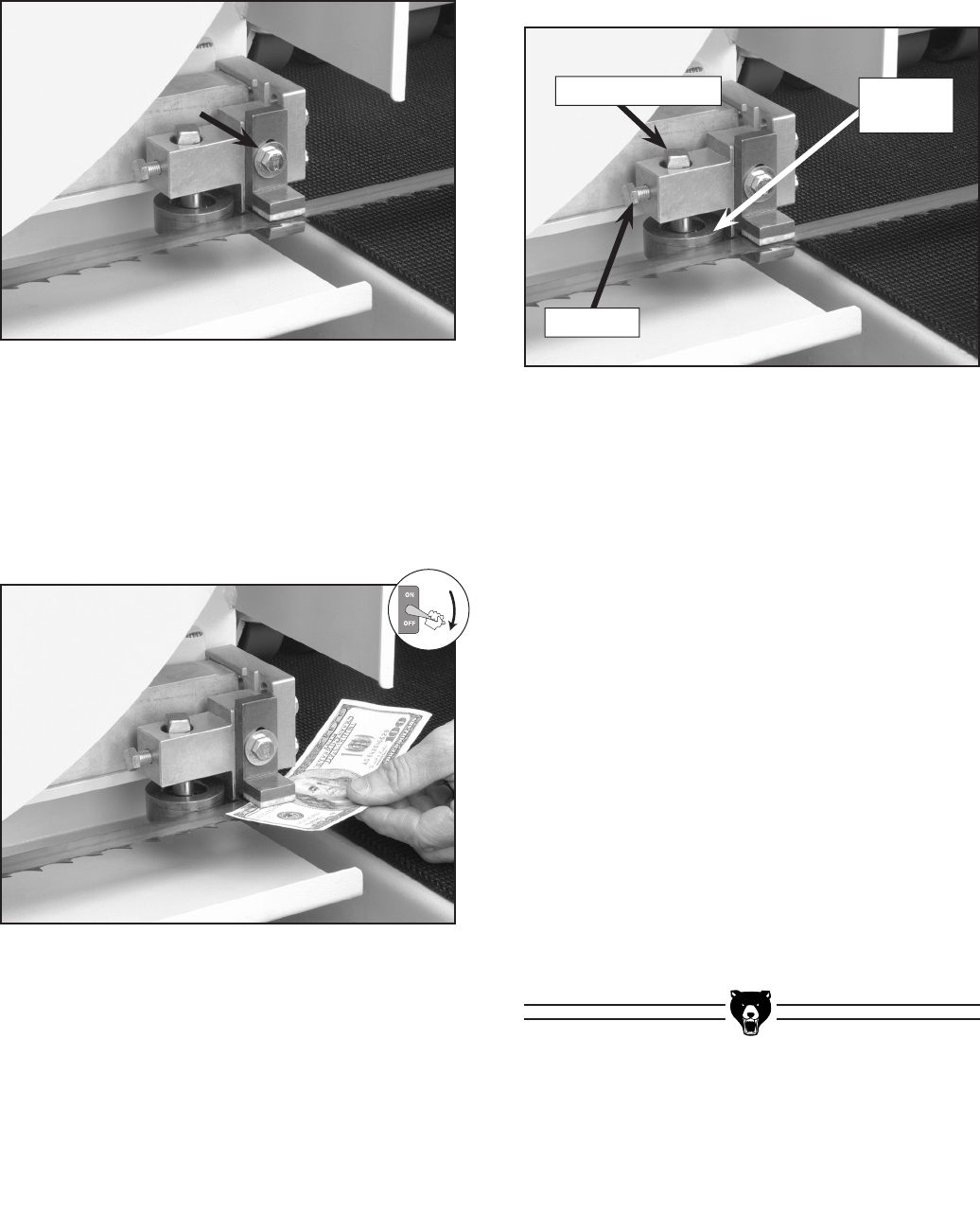

Figure 19. Support bearing components.

To adjust the support bearings:

1. Loosen the lock bolt approximately

1

⁄4 turn.

Note—If you loosen the lock bolt too much,

the support bearing will fall out of place.

2. Turn the adjustment shaft until the support

bearing is positioned approximately 0.016"

behind the back of the blade. Use a feeler

gauge or four thicknesses of a dollar bill to

check this.

3. Tighten the lock bolt, and repeat with the

other support bearing.

4. Test the adjustment of the support bearings

by spinning the wheels by hand, at full blade

tension, in the same direction of operation.

While you are spinning the wheels, the sup

-

port bearings should not turn. (The support

bearings should only turn during cutting

operations.)

Support Bearing

The support bearing is positioned behind the

blade to brace it from pushing backwards during

a cut.

Figure 19 shows the support bearing com-

ponents to clarify the adjustment instructions.

Figure 17. Guide block adjustment bolt.

Figure 18. Dollar bill between upper guide block

and blade.

2. Slide the upper guide block up, place a dollar

bill (as a quick gauge for 0.004" clearance)

underneath the upper guide block, then let

the upper guide block slide down to sand

-

wich the dollar between the blade and the

upper guide block as shown in

Figure 18.

3. Keep the dollar bill in place and tighten the

upper guide block.

4. Remove the dollar bill.

5. Repeat Steps 1-4 with the blade guide on

the other side of the conveyor.

To adjust the upper guide block:

1. Loosen the guide block adjustment bolt

shown in

Figure 17.

Adjustment Shaft

Lock Bolt

Support

Bearing