-40- G0504 16" Horizontal Resaw Bandsaw

3. Disconnect the resaw from the power

source!

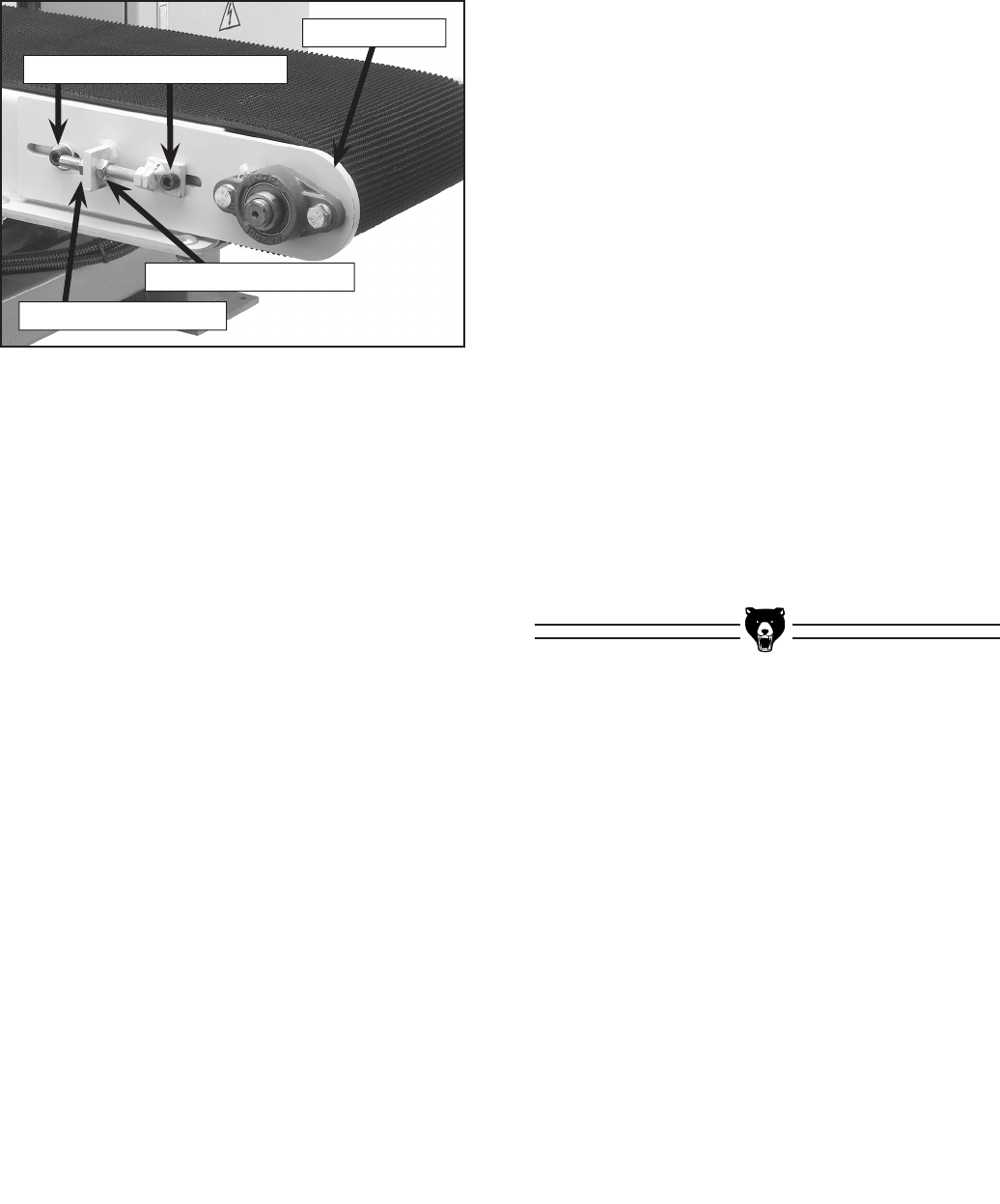

4. Loosen the roller bracket (see Figure 42) by

turning the roller bracket cap screws

3

⁄4 of a

turn.

Figure 42. Roller bracket cap screws and

adjustment nuts.

Roller Bracket Cap Screws

Rear Adjustment Nut

Front Adjustment Nut

Roller Bracket

5. Loosen the rear adjustment nuts away from

the bracket plate.

6. Mark the front adjustment nut with a felt-

tipped pen or a piece of tape, and thread

the front adjustment nut all the way up, while

keeping track of the number of full turns that

you moved the nut.

Note—Write the number of turns down, so

you do not forget. Remembering this number

is an important part of the re-assembly pro

-

cess.

7. Slide the roller brackets toward the body of

the resaw to loosen the belt.

8. Remove the stiff cable from the center of the

seam to separate it.

9. Remove the old conveyor belt from the con-

veyor table, and replace the new conveyor

belt in its place.

10. Mesh the seam “teeth” together on the new

belt, and insert the stiff cable into the center

of the seam to lock it together.

11. Slide the roller brackets away from the body

of the resaw to tighten the belt.

12. Turn the front adjustment bolts the exact

number of rotations that you turned them

when you loosened them.

Note—The new belt may be tighter than the

old one because it has not been broken-in. If

this is the case, deduct one or two turns from

your original number of turns.

13. Run the conveyor belt to check the tracking.

If the belt starts tracking to one side, stop the

resaw and perform the “Tracking Conveyors”

instructions that are located on

Pages 38.