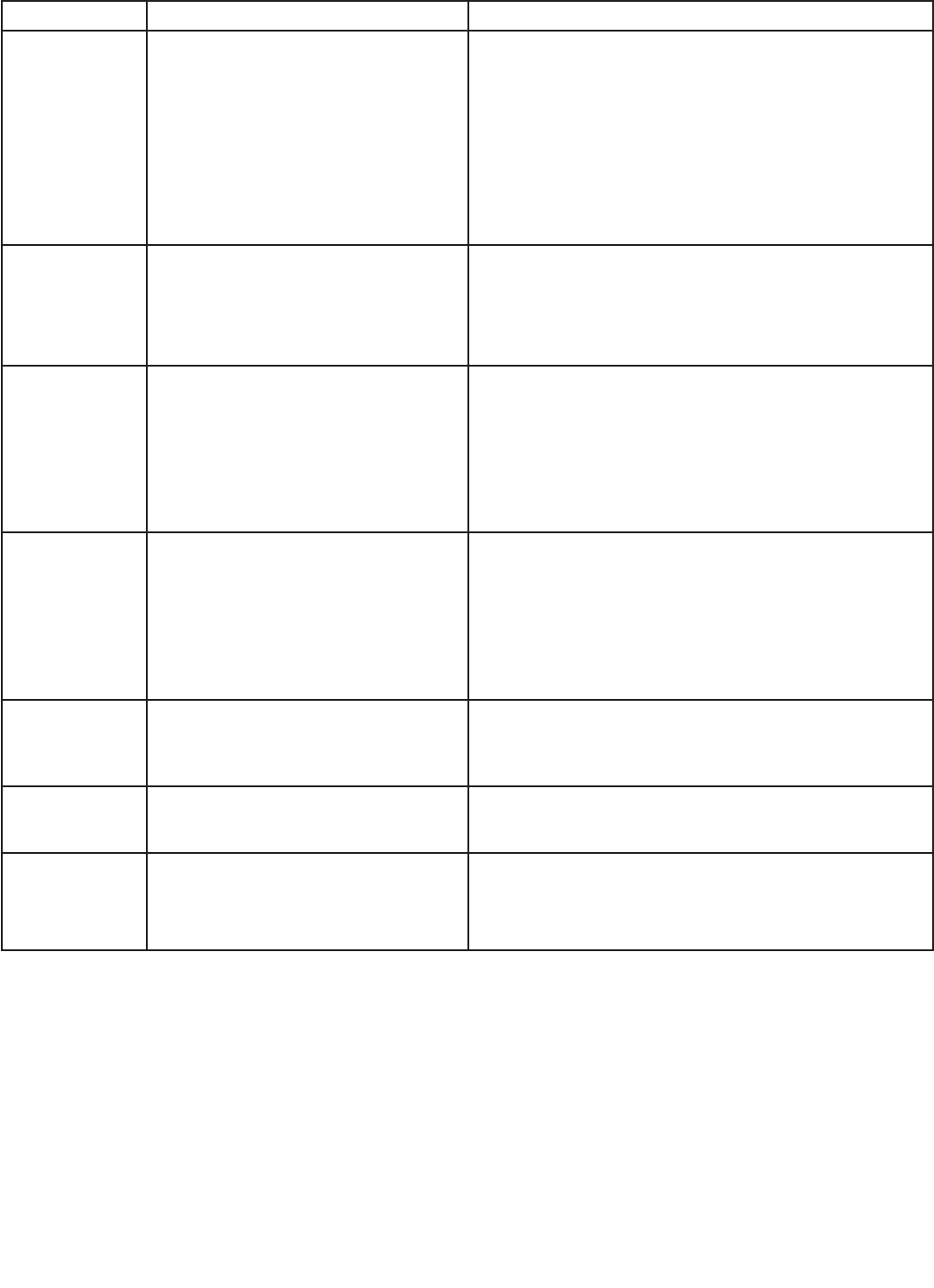

G0504 16" Horizontal Resaw Bandsaw -45-

Symptom Possible Cause Possible Solution

Machine has

excessive vibra

-

tion or noisy oper

-

ation.

1. Motor or component is loose.

2. Blade weld at fault or teeth are broken.

3. V-belt(s) worn or loose.

4. Motor fan is rubbing on fan cover.

5. Pulley is loose.

6. Machine incorrectly mounted.

7. Motor bearings are at fault.

8. Blade is at fault.

1. Retighten/replace stripped or damaged bolts/nuts.

2. Replace blade.

3. Inspect/replace belts (refer to

Page 37).

4. Replace dented fan cover; replace loose/damaged fan.

5. Realign/replace shaft, pulley, setscrew, or key.

6. Tighten/replace floor mounts; relocate/shim machine.

7. Replace bearings.

8. Replace warped, bent, or twisted blade; resharpen dull

blade.

Machine slows

when cutting.

1. Feed rate is too fast.

2. Wood has a high moisture content.

3. V-belt does not have enough tension

and is slipping on the pulleys.

4. V-belt is worn out.

1. Slow down the feed rate.

2. Only cut properly dried wood.

3. Tighten the V-belt (

Page 36).

4. Replace V-belt (

Page 37).

Blade does not

run evenly on

the wheels.

1. Blade support bearings set incorrectly.

2. Wheels have built up pitch or dust.

3. Wheels are not coplanar.

4. Shape of wheels has changed from

long term use and wear.

1. Adjust blade support bearings (

Page 21).

2. Clean wheels of all pitch and dust.

3. Call the Grizzly Service Department at (570) 546-9663 for

help determining if your wheels really are NOT coplanar;

adjust wheels to be coplanar as described on

Page 41.

4. Replace wheels.

Blade does not

cut evenly.

1. Blade is not properly tensioned.

2. Wheels are not coplanar.

3. Tooth set is uneven.

4. Teeth are sharper on one side than the

other.

1. Adjust blade tension (

Page 19).

2. Call the Grizzly Service Department at (570) 546-9663 for

help determining if your wheels really are NOT coplanar;

adjust wheels to be coplanar as described on

Page 41.

3. Replace blade.

4. Replace blade.

Blade makes a

squealing noise,

especially on

startup.

1. V-belt is loose.

2. V-belt is worn out.

1. Tighten the V-belt (

Page 36).

2. Replace V-belt (

Page 37).

Ticking sound

when the saw is

running.

1. Blade weld is contacting the guide

blocks or support bearing.

1. Use the Model G2516 stone to smooth the blade weld.

Hydraulic pump is

noisy or hydraulic

system operates

erratically.

1. Pump is restricted.

2. Filter is clogged.

3. Tank screen is clogged.

4. Damaged hydraulic pump or motor.

1. Inspect and clean breather cap, filter, and tank screen.

2. Perform minor service (

Page 32).

3. Perform major service (

Page 33).

4. Replace pump or motor. See hydraulic specialist.