G0504 16" Horizontal Resaw Bandsaw -41-

Blade Tracking and

Wheel Alignment

Blade tracking on the Model G0504 consists

of adjusting the wheels to be nearly coplanar

(coplanar=both wheels even and parallel), but

having the outside edge of the wheel approxi

-

mately 0.020"-0.040" behind the inside edge of

the wheel to compensate for wheel toe-in when

the blade is fully tensioned.

Because of the large size of this machine and

the wheel toe-in factor, this procedure is time

consuming and requires a great deal of trial and

error. Make sure you really need to perform this

procedure before attempting it.

Also, to complete this procedure you will need to

make four precision gauge blocks and have a 6'

long straightedge.

To adjust the wheels to be

coplanar:

1. Disconnect the resaw from the power

source!

2. Open the wheel cover.

3. Remove the blade.

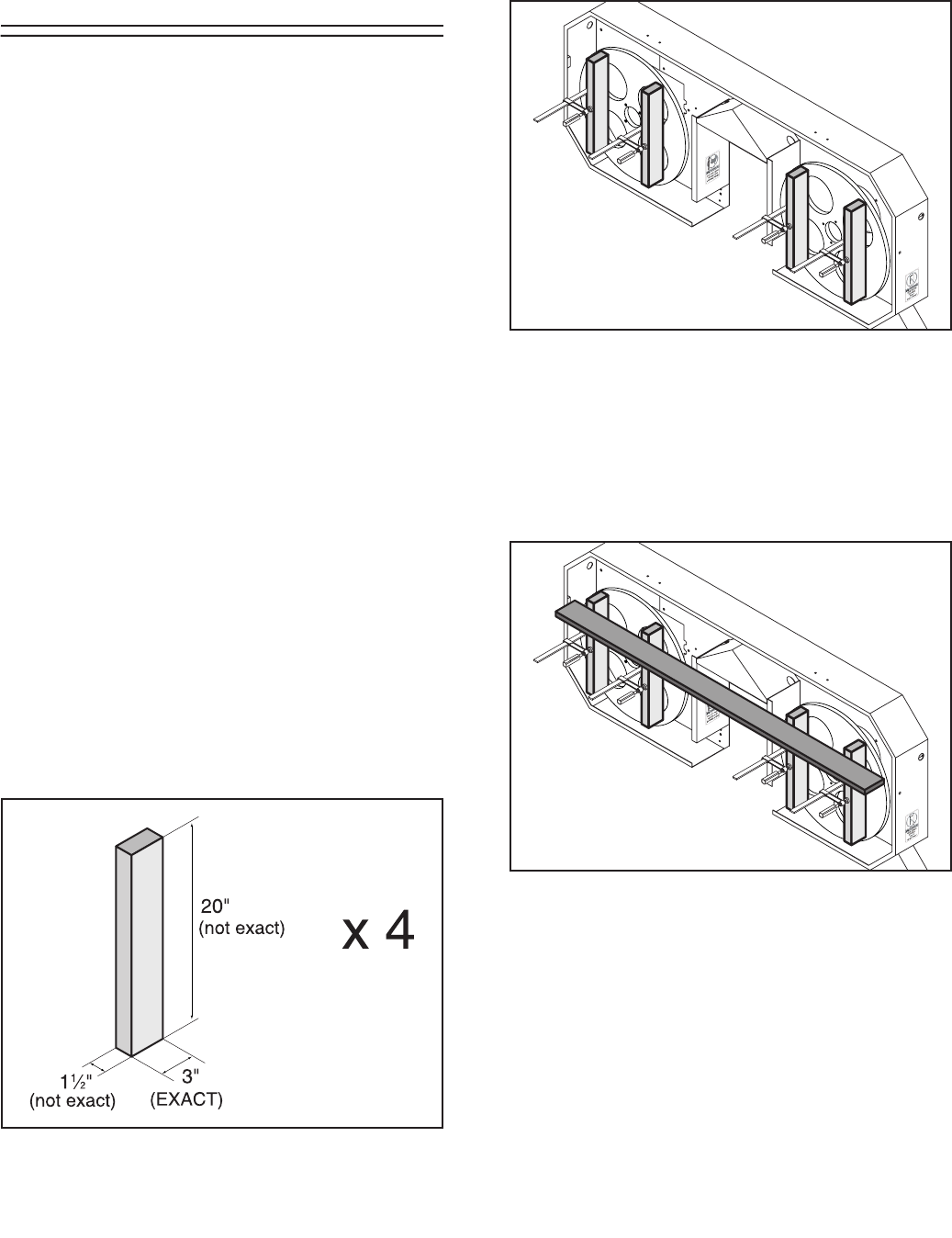

4. Using 2x4’s, make four precision gauge

blocks to the specifications shown in

Figure

43.

Figure 43. Precision gauge block dimensions.

Figure 44. Precision gauge blocks clamped in

position on wheels.

Figure 45. Straightedge placement when check-

ing the upper portion of the wheels.

5. Clamp the gauge blocks to the wheels as

shown in

Figure 44.

6. Place the straightedge across the top of the

gauge blocks, as shown in

Figure 45, and

examine how the wheels line up with each

other.