-34-

Model G0690/G0691 (Mfg. 11/10+)

The riving knife included with this machine is 0.1"

(2.5mm) thick and is only designed for 10" diam-

eter blades.

When choosing a main blade, make sure the

blade size meets the requirements listed below.

The thickness of the blade body and teeth can be

measured with calipers or any precision measur-

ing device.

Blade Size Requirements:

• Body Thickness: 0.071"-0.094" (1.8-2.4mm)

• Kerf (Tooth) Thickness: 0.102"-0.126"

(2.6-3.2mm)

Blade Requirements

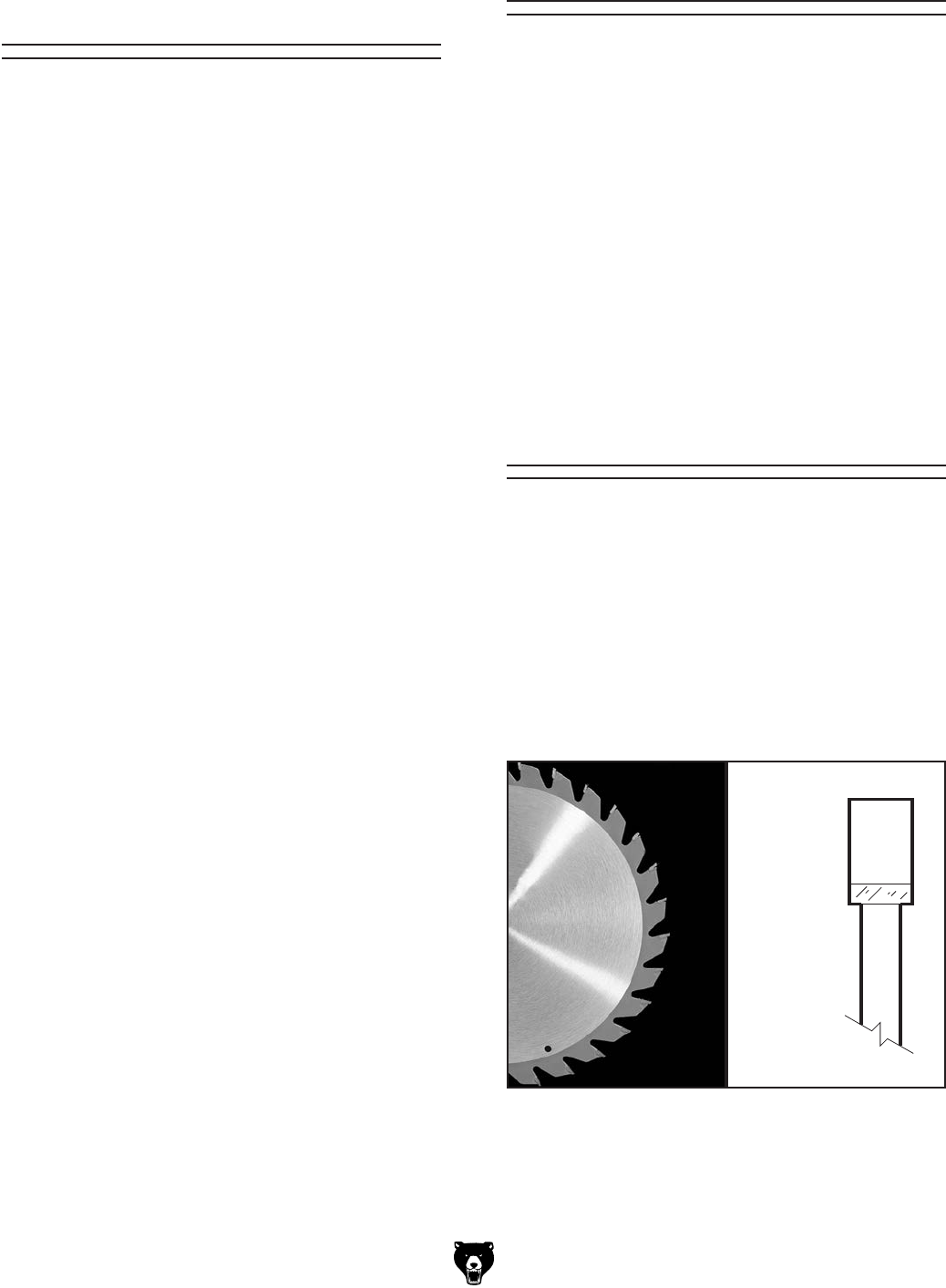

Figure 44. Ripping blade.

Blade Selection

This section on blade selection is by no means

comprehensive. Always follow the saw blade

manufacturer's recommendations to ensure safe

and efficient operation of your table saw.

Ripping Blade Features:

•

Best for cutting with the grain

•

20-40 teeth

•

Flat-top ground tooth profile

•

Large gullets for large chip removal

Flat

Top

Blade

Workpiece

Inspection

Some workpieces are not safe to cut on this

machine or may need to be modified before they

can be safely cut. Before cutting, inspect all

workpieces for the following:

• Material Type:Thismachineisintendedfor

cutting natural and man-made wood prod

-

ucts, laminate covered wood products,

and

someplastics.Cuttingdrywallor

cementitious

backerboardcreatesextremelyfinedust

and

may reduce the life of the motor

bearings.

ThismachineisNOTdesignedtocut

metal,

glass,stone,tile,etc.;cuttingthese

materials

withatablesawgreatlyincreasestherisk

of

injuryanddamagetothesaworblade.

•

Foreign Objects: Nails, staples, dirt,

rocks

and other foreign objects are often embed

-

ded in wood. While cutting, these

objects

canbecomedislodged andhitthe

operator,

cause kickback, or break the blade,

which

mightthenfly apart.Alwaysvisually

inspect

yourworkpiecefortheseitems.Iftheycan’

t

beremoved,DONOTcuttheworkpiece.

•

Large/Loose Knots: Loose knots

can

become dislodgedduring the cuttingopera

-

tion. Large knots can cause kickback

and

machine damage. Choose workpieces

that

donothavelarge/looseknotsorplan

ahead

toavoidcuttingthroughthem.

•

Wet or “Green” Stock:Cuttingwoodwith

a

moisturecontentover20%causesunneces

-

sarywearontheblades,increasestherisk

of

kickback,andyieldspoorresults.

•

Excessive Warping:Workpieceswithexces

-

sivecupping,bowing,ortwistingaredanger

-

ous to cut because they are unstable

and

maymoveunpredictablywhenbeingcut.

•

Minor Warping:Slightlycupped

workpieces

can be safely supported with cupped

side

facing the table or fence; however, work

-

piecessupportedonthebowedsidewill

rock

duringthecut,whichcouldcausekickback.