Model G0690/G0691 (Mfg. 11/10+)

-51-

5"

5"

4" Slot

(Top View)

(Side View)

3

/

8

"

Countersink on Bottom

1

/

4

" Hole

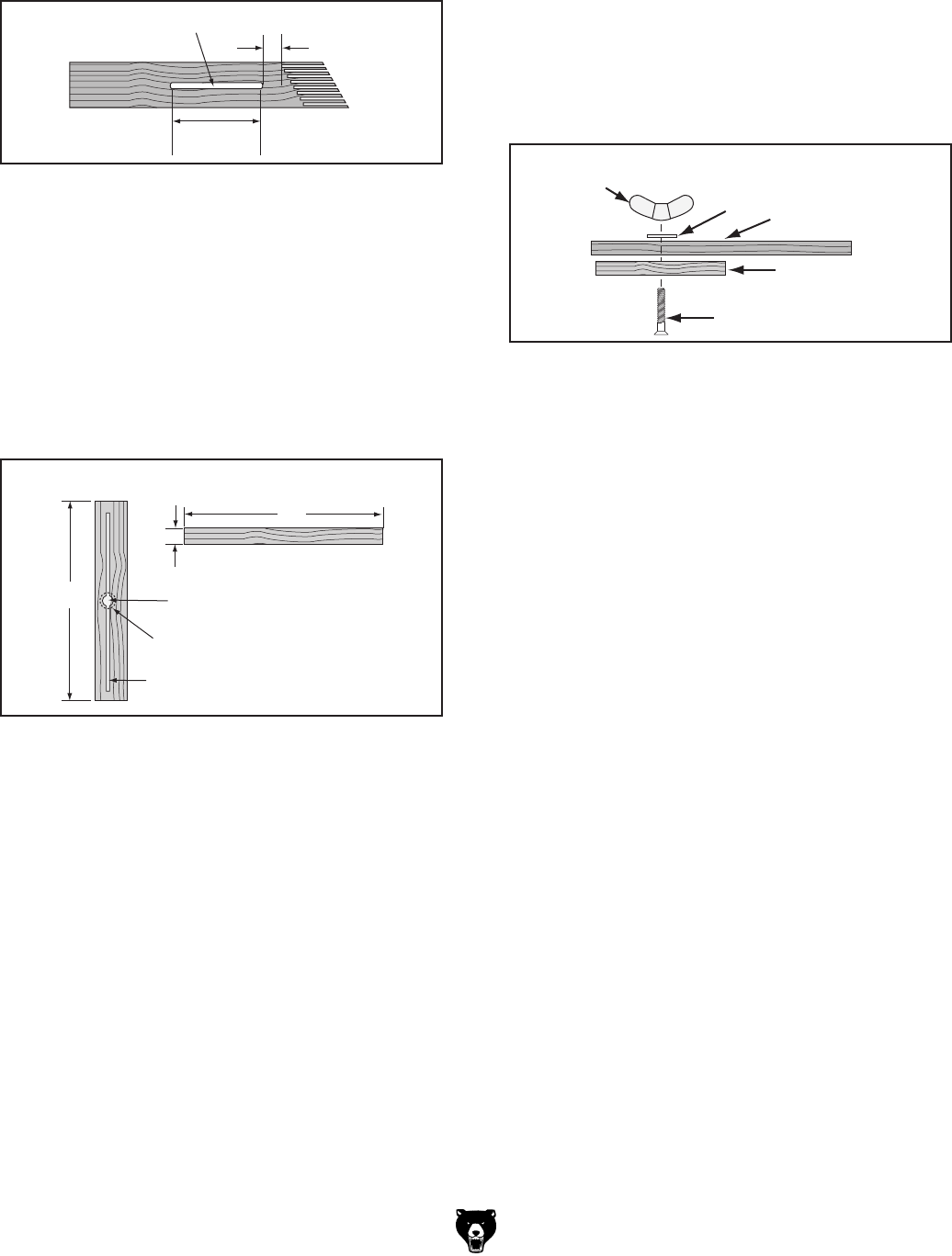

Figure 74. Miter bar pattern.

5. Cut a miter bar that will fit in the table miter

slot approximately 5" long, as shown in

Figure 74.

Tip: Consider making the miter bar longer for

larger featherboards—approximately half the

length of the total featherboard—to support

the force applied to the featherboard during

use.

7. Mark a 4" line through the center of the coun-

tersunk hole in the center, then use a jig saw

with a narrow blade to cut it out.

8. Assemble the miter bar and featherboard

with a

1

⁄4"-20 x flat head screw, flat washer,

and a wing nut or a star knob (see Figure

75). Congratulations! Your featherboard is

complete.

4. Rout a

1

⁄4"–

3

⁄8" wide slot 4"–5" long in the

workpiece and 1"–2" from the short end of the

featherboard (see Figure 73).

Figure 73. Slot routed in featherboard.

1"-2"

4"-5"

1

/

4

"-

3

/

8

" Slot

(Side View)

Wing Nut

Miter Bar

Featherboard

Flat Head Screw

Flat Washer

Figure 75. Assembling miter slot featherboard

components.

Note: The routed slot, countersink hole, and

the flat head screw are essential for the miter

bar to clamp into the miter slot. When the

wing nut is tightened, it will draw the flat head

screw upward into the countersunk hole. This

will spread the sides of the miter bar and

force them into the walls of the miter slot,

locking the featherboard in place.

Tip: The length of the flat head screw depends

on the thickness of the featherboard—though

1

1

⁄2" to 2" lengths usually work.

Now, proceed to Mounting Featherboard in

Miter Slot on Page 52.

6. Drill a

1

⁄4" hole in the center of the bar, then

countersink the bottom to fit a

1

⁄4"-20 flat head

screw.