-72-

Model G0690/G0691 (Mfg. 11/10+)

Miter Gauge

Adjustments

The miter gauge can be adjusted so it is per-

pendicular to the blade and so it is snug in the

T-slot.

Tools Needed Qty

90° Square ........................................................ 1

45° Square ........................................................ 1

Hex Wrench 2.5mm ........................................... 1

Hex Wrench 2mm .............................................. 1

Hex Wrench 3mm .............................................. 1

Checking/Setting 90° Stops

1. DISCONNECT THE SAW FROM POWER!

2. Slide the miter gauge into the T-slot on the

table.

3. Loosen the miter gauge lock knob, pull out

the positive stop knob, then pivot the miter

gauge body to 90° so the stop knob springs

into position.

4. Place the square evenly against the face of

the miter gauge and the blade, as shown in

Figure 123.

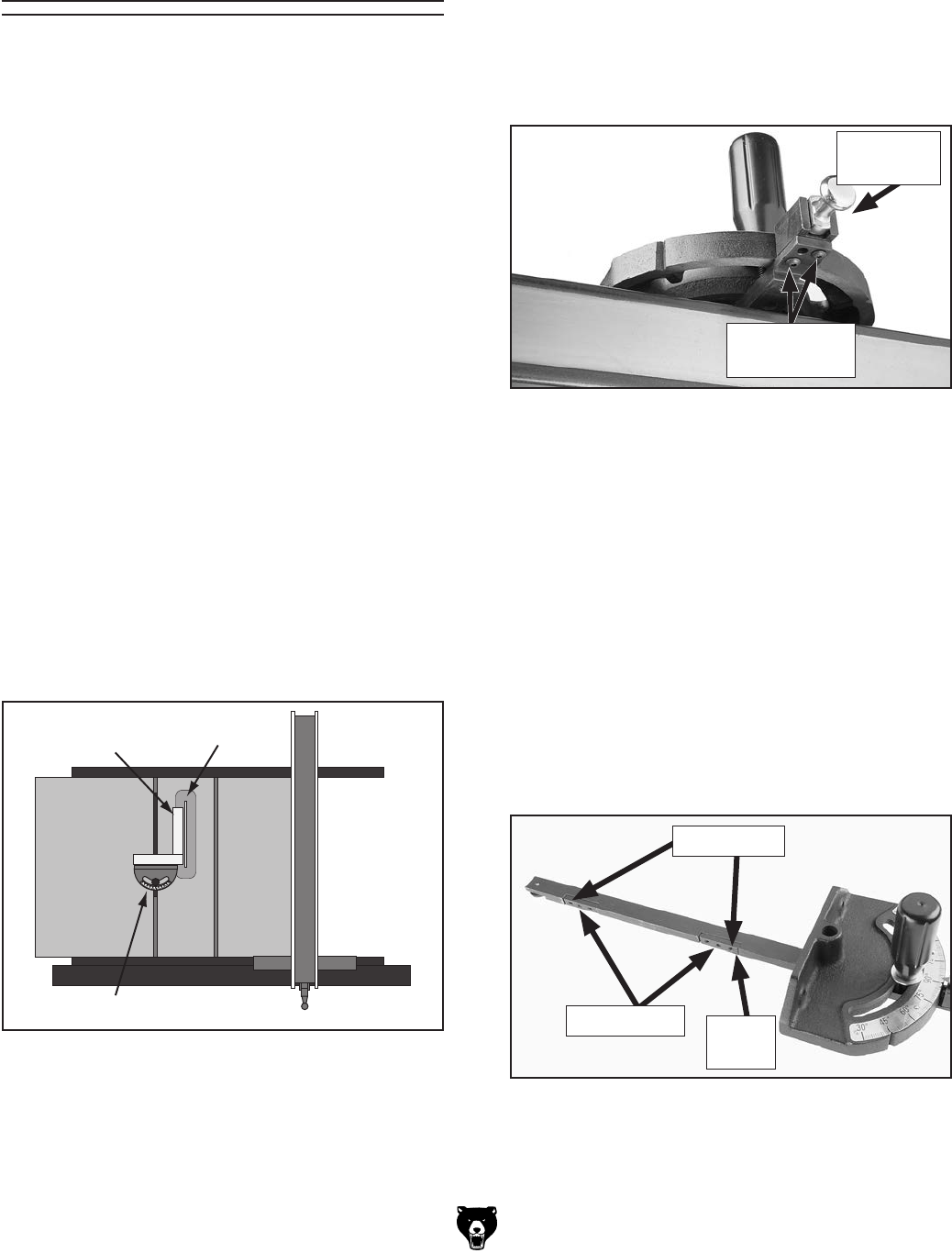

Figure 123. Checking 90° stop on miter gauge.

Square

Miter Gauge

Blade

— If the square does not touch the miter body

and blade body evenly at the same time,

then proceed to Step 5.

5. Loosen the button head cap screws on the

positive stop knob block (see Figure 124),

adjust the miter body until it is flush with the

square, then tighten the screws.

Figure 124. Screws for adjusting miter gauge

body.

— If the square touches the miter body and

the body of the blade (not the teeth) evenly

at the same time, then it is square to the

blade and the 90° stop is set correctly. No

further adjustments are necessary.

6. Loosen the screw on the front of the miter

bar, adjust the pointer to 0°, then tighten the

screw.

Adjusting Miter Bar Tightness

The miter bar can be adjusted so it fits more

tightly in the miter slot.

To adjust the miter bar tightness:

1. Loosen the cap screw on each guide block

(Figure 125), adjust the set screws as need-

ed, then tighten the cap screw.

Figure 125. Screws for adjusting miter bar in

miter slot.

Set Screws

Positive

Stop Knob

Button Head

Cap Screws

Cap Screws

Guide

Block