Model G0690/G0691 (Mfg. 11/10+)

-37-

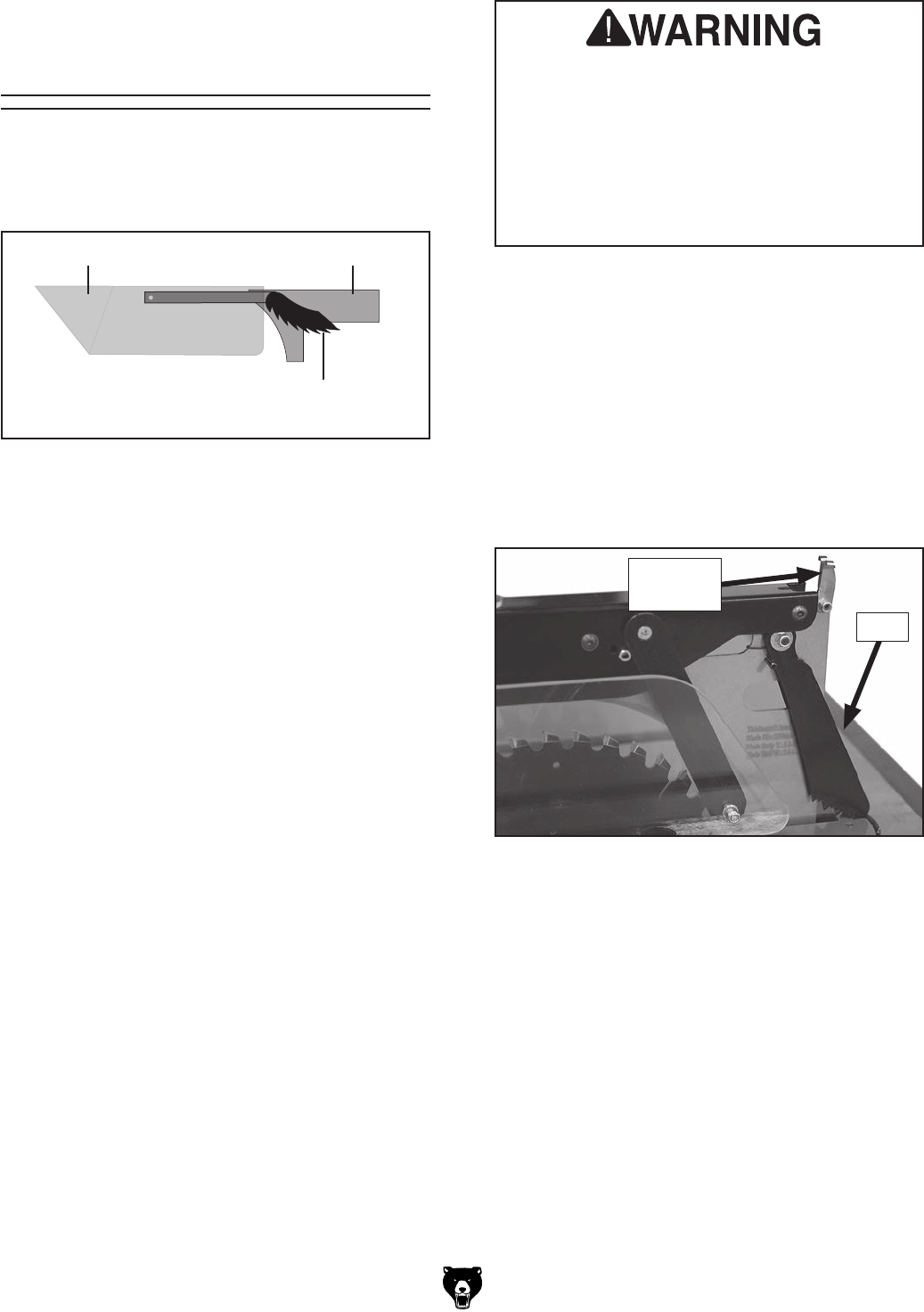

Anti-Kickback Pawls

The anti-kickback pawls allow the workpiece to

travel in only one direction. If the workpiece moves

backwards, such as during a kickback, the pawls

will dig into the workpiece to slow or stop it.

To work properly, the pawls must return to their

bottom-most position after pivoting, as shown in

Figure 51, and they must not be engaged in the

arresting hooks.

Figure 51. Pawls in return position.

Pawl

Arresting

Hooks

In order to work properly, the spreader

cannot be bent or misaligned with the blade.

If the spreader gets accidentally bent, take

the time to straighten it or just replace it.

Using a bent or misaligned spreader will

increase the risk of kickback! Refer to

Page 68 to check or adjust alignment if

necessary.

Blade Guard

The guard encloses the top of the blade to reduce

the risk of accidental blade contact and contain

flying chips or dust.

The

guard is designed to lift as the workpiece is

pushed into the blade

,

remain in contact with the

workpiece

during the cut

, then return to a resting

position against the table when the cut is com-

plete. When installed and properly maintained,

the guard is an excellent tool for reducing the risk

of injury when operating the table saw.

To ensure that the guard

does its job effectively,

it

MUST be installed and adjusted so that it moves

up and down properly to accommodate workpiec-

es and maintain coverage over the blade.

Blade Guard

Assembly

The term "blade guard" refers to the assembly

that consists of the guard, spreader, and anti-

kickback pawls (see Figure below). Each of these

components have important safety functions.

Figure 50. Blade guard assembly components.

Clear Shield Spreader

Anti-Kickback

Pawl

Spreader

The spreader is a metal plate that prevents the

freshly cut pieces of the workpiece from pinching

the backside of the blade

and causing a

kickback.

It

also acts as a barrier behind the blade to

shield

hands from being pulled into the blade if a kick-

back occurs.