Model T25920/T25926 (Mfd. Since 08/14)

-15-

Site Considerations

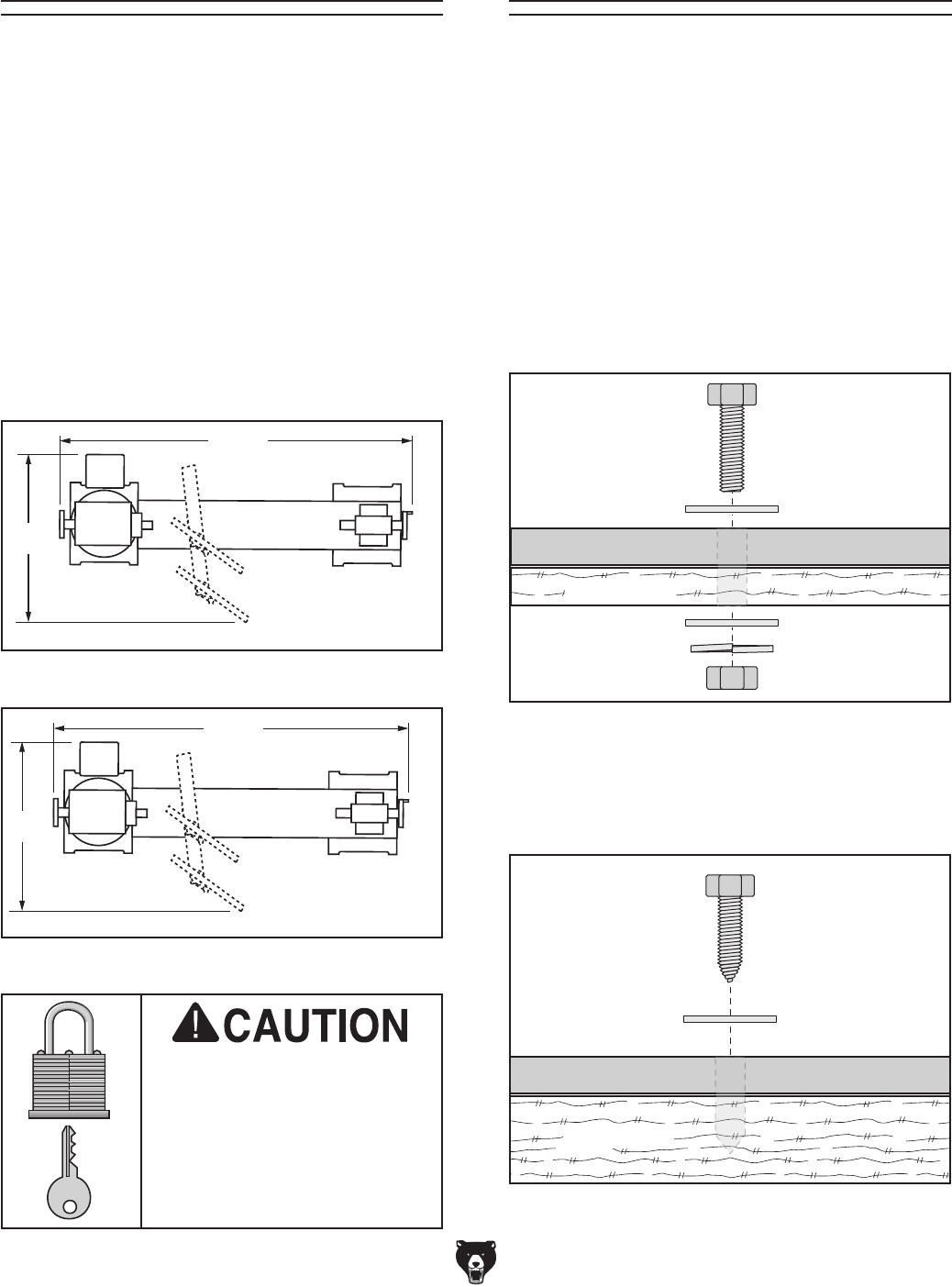

Figure 8. T25920 minimum working clearances.

Figure 9. T25926 minimum working clearances.

Children and visitors may be

seriously injured if unsuper-

vised around this machine.

Lock entrances to the shop

or disable start switch or

power connection to prevent

unsupervised use.

Workbench Load

Refer to the Machine Data Sheet for the weight

and footprint specifications of your machine.

Some workbenches may require additional rein-

forcement to support the weight of the machine

and workpiece materials.

Consider anticipated workpiece sizes and addi-

tional space needed for auxiliary stands, work

tables, or other machinery when establishing a

location for this machine in the shop. Below is

the minimum amount of space needed for the

machine.

Placement Location

Figure 11. "Direct Mount" setup.

Machine Base

Workbench

Lag Screw

Flat Washer

Another option is a "Direct Mount" (see example

below) where the machine is secured directly to

the workbench with lag screws and washers.

Bench Mounting

The base of this machine has mounting holes

that allow it to be fastened to a workbench or

other mounting surface to prevent it from moving

during operation and causing accidental injury or

damage.

The strongest mounting option is a "Through

Mount" (see example below) where holes are

drilled all the way through the workbench—and

hex bolts, washers, and hex nuts are used to

secure the machine in place. The rubber feet

on the bottom of the base must be removed to

"Through Mount" the lathe.

Machine Base

Workbench

Hex

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

38

3

⁄4"

17

37

3

⁄4"

17

3

⁄4"

Figure 10. "Through Mount" setup.