Model T25920/T25926 (Mfd. Since 08/14)

-19 -

Adjusting Spindle

Speeds

A

B

C

= High Range

1600–3800 RPM

= Mid Range

1250–2800 RPM

= Low Range

650–1450 RPM

A

B

C

Spindle

Motor

(Viewed from Back of Headstock)

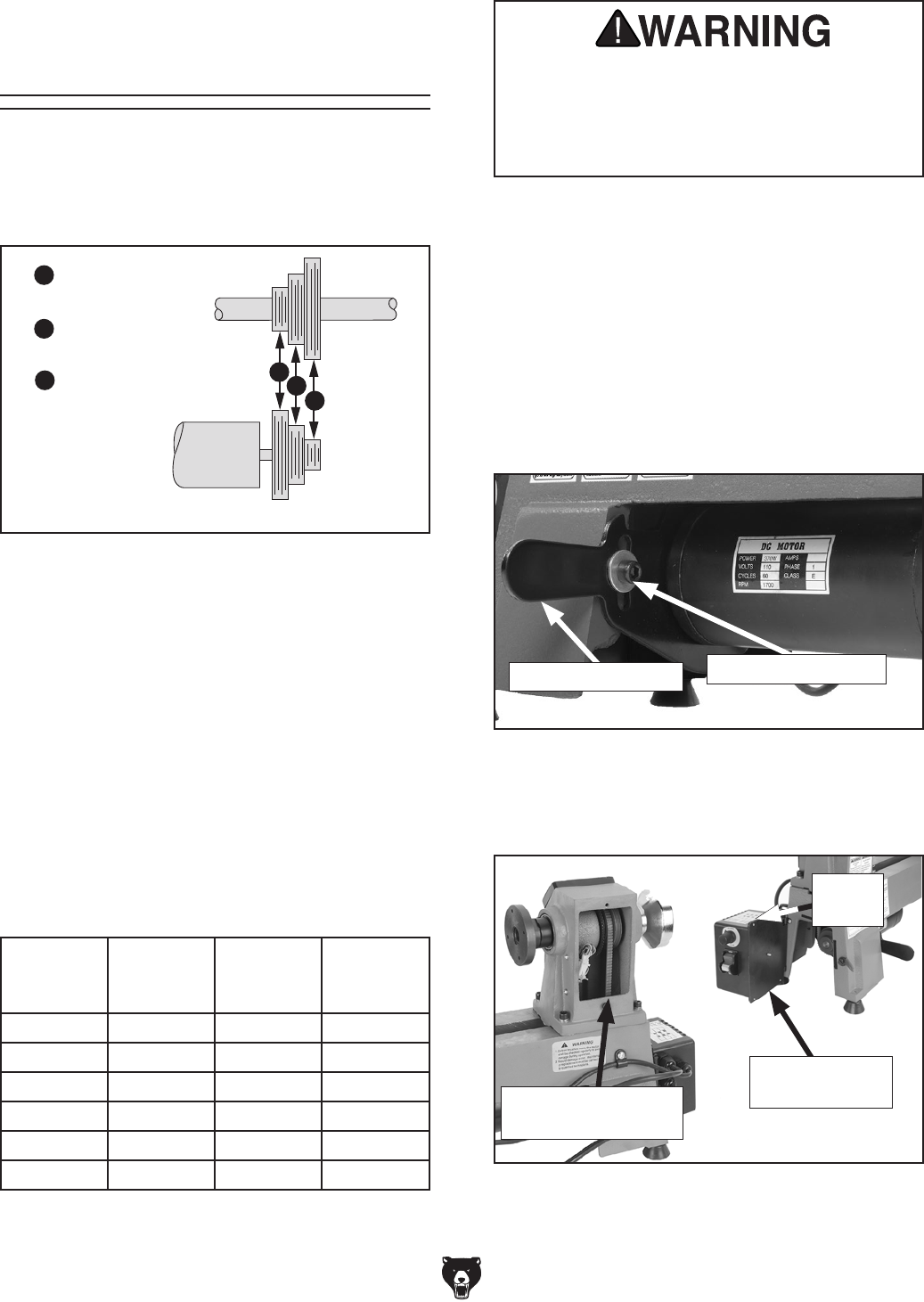

Figure 14. Speed ranges for each belt position.

Your lathe has three speed ranges for maximum

turning options. These ranges are selected by

changing belt positions on the motor and spindle

pulleys (see Figure 14).

High range (A) is best when turning a workpiece

where a clean finish is required and only light

cuts are made. Mid range (B) is a compromise

between the high and low ranges. Low range

(C), which has more torque, is best when turn-

ing a workpiece where a lot of material must be

removed and a rough finish does not matter. Use

the speed dial to adjust the spindle speed within

each range.

Refer to the speed recommendations chart in

Figure 15 to choose the appropriate RPM for your

operation. Then choose the speed range that will

include the selected RPM.

Always choose correct spindle speed for

your operation. Using wrong speed may lead

to workpiece breaking loose or being thrown

from lathe at a high rate of speed, causing

fatal or severe impact injuries.

To change speeds:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen belt tension screw (see Figure 16).

Be sure belt tension lever moves freely to

release tension from belt.

3. Open side access cover and remove rear

access cover (see Figure 17).

Figure 17. Side and rear access covers.

Speed

Chart

Rear Access Cover

Removed

Side Access

Cover Opened

Figure 16. Belt tension lever.

Belt Tension Lever

Belt Tension Screw

Tool Needed:

Hex Wrench 6mm .............................................. 1

Diameter

of Work-

piece

Roughing

RPM

General

Cutting

RPM

Finishing

RPM

Under 2" 1520 3000 3000

2–4" 760 1600 2480

4–6" 510 1080 1650

6–8" 380 810 1240

8–10" 300 650 1000

10–12" 255 540 830

Figure 15. Speed recommendations.