Model T25920/T25926 (Mfd. Since 08/14)

-25-

Spindle Turning

Spindle turning is the operation performed when

a workpiece is mounted between the headstock

and the tailstock, as shown in Figure 32.

Figure 32. Typical spindle turning operation.

To set up a spindle turning operation:

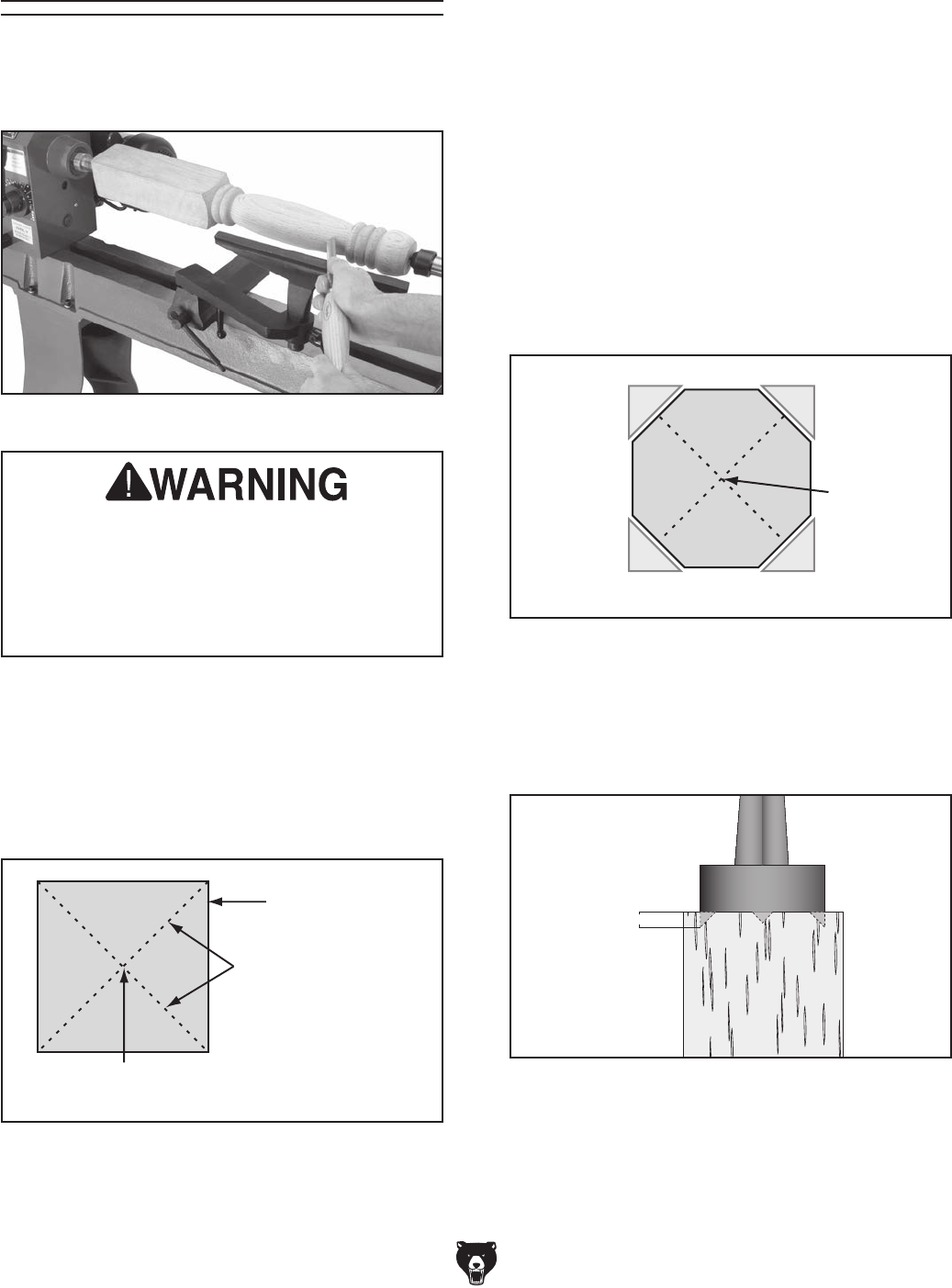

1. Find center point of both ends of your

workpiece by drawing diagonal lines from

corner to corner across end of workpiece, as

shown in Figure 33.

Figure 33. Workpiece marked diagonally from

corner to corner to determine the center.

Workpiece

Workpiece

Center

Pencil Lines

Marked Diagonally

Across Corners

2. Make center mark by using wood mallet and

tapping point of spur center into center of

workpiece on both ends.

3. Using

1

⁄4" drill bit, drill

1

⁄4" deep hole at center

mark on end of workpiece to be mounted on

headstock spur center.

4. To help embed spur center into workpiece,

cut

1

⁄8" deep saw kerfs in headstock end of

workpiece along diagonal lines marked in

Step 1.

5. If your workpiece is over 2" x 2", cut corners

off workpiece lengthwise to make turning

safer and easier (see Figure 34).

6. Drive spur center into end center mark of

workpiece with wood mallet to embed it at

least

1

⁄4" into workpiece, as shown in Figure

35.

¼"

Figure 35. Spur center properly embedded.

Workpiece

Center

Figure 34. Corners of workpiece removed.

Make sure the headstock and tailstock cen-

ters are properly aligned before beginning

any turning operation. Failure to observe

this warning could result in the workpiece

being thrown from the lathe, resulting in

serious personal injury.