-34-

Model T25920/T25926 (Mfd. Since 08/14)

Tensioning &

Replacing Belt

Tools Needed:

Hex Wrenches 3mm, 6mm ...........................1 Ea

Rubber/Wood Mallet .......................................... 1

The drive belt stretches as the lathe is used.

Most of the stretching will occur during the first

16 hours, but may continue with further use. If the

lathe loses power while making a cut, the belt may

be slipping and need tensioning. If the belt shows

signs of excessive wear, or damage, replace it.

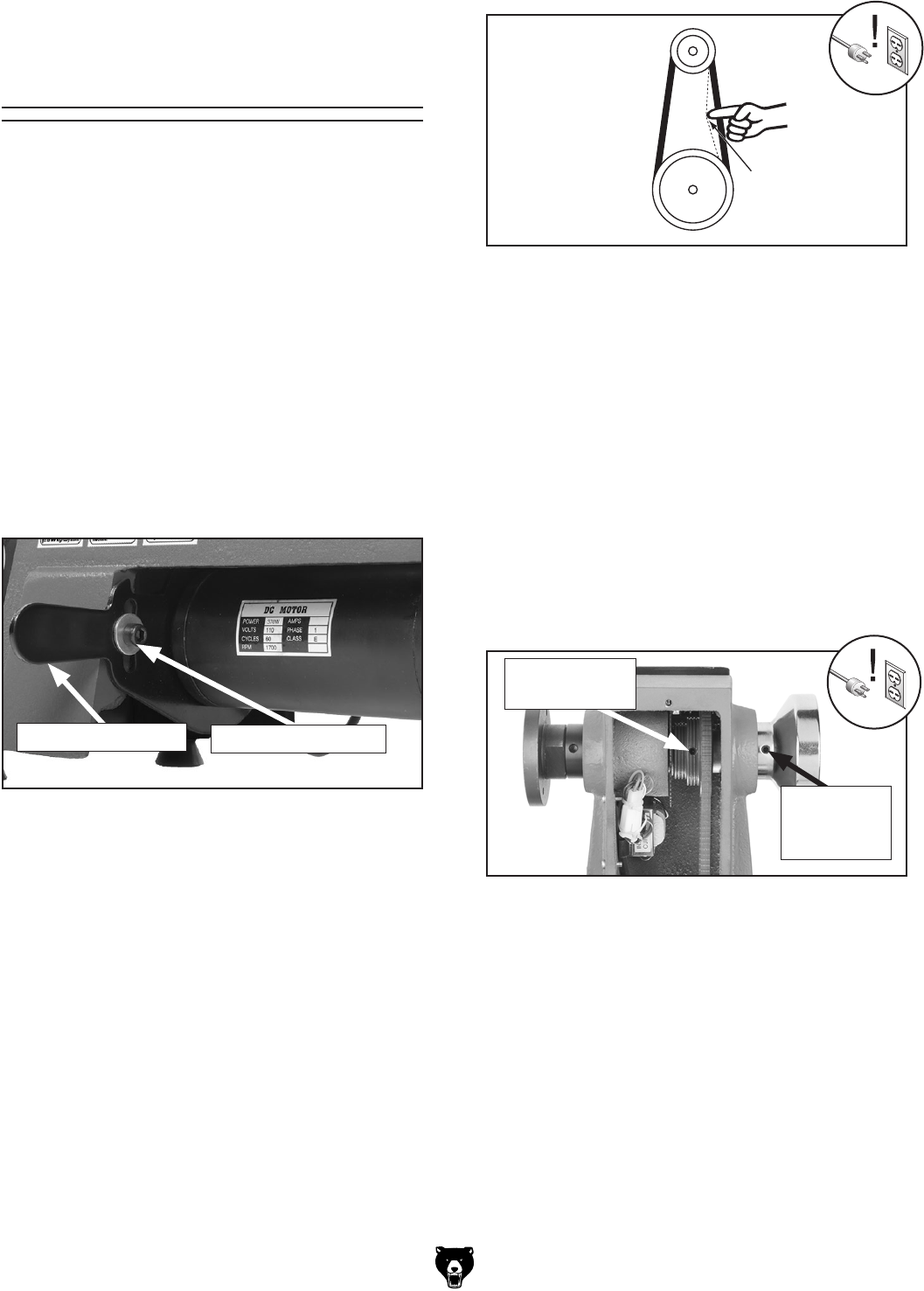

Figure 49. Belt tension controls.

Belt Tension Lever

Belt Tension Screw

Tensioning Belt

1. DISCONNECT MACHINE FROM POWER!

2. Remove rear access cover and loosen belt

tension screw (see Figure 49).

3. Press belt tension lever down, then tighten

belt tension screw.

4. Press belt with moderate pressure in center

to check tension. Belt is correctly tensioned

when there is approximately

1

⁄2" deflection

when pushed as shown in Figure 50.

— If there is more than

1

⁄2" deflection repeat

the tensioning procedure until it is correct.

If tension cannot be achieved replace belt.

Pulley

Deflection

Pulley

Figure 50. Checking belt deflection.

1

⁄2"

Replacing Belt

1. DISCONNECT MACHINE FROM POWER!

2. Remove rear access cover and open side

access cover.

3. Release belt tension, then remove belt from

motor pulley.

4. Loosen set screws on spindle handwheel (see

Figure 51), and turn clockwise to unthread

and remove.

Figure 51. Set screw locations.

Spindle

Handwheel

Set Screw

Spindle Pulley

Set Screw

5. Re-install rear access cover.

5. Loosen spindle pulley set screw.

6. Tap spindle far enough out of headstock

so belt can be removed (see Figure 52 on

Page 35). A rubber or wooden mallet may be

required. Take care not to damage spindle

threads or lose parts. DO NOT remove spin-

dle pulley.