Model T27313 (Mfd. Since 01/15)

-11-

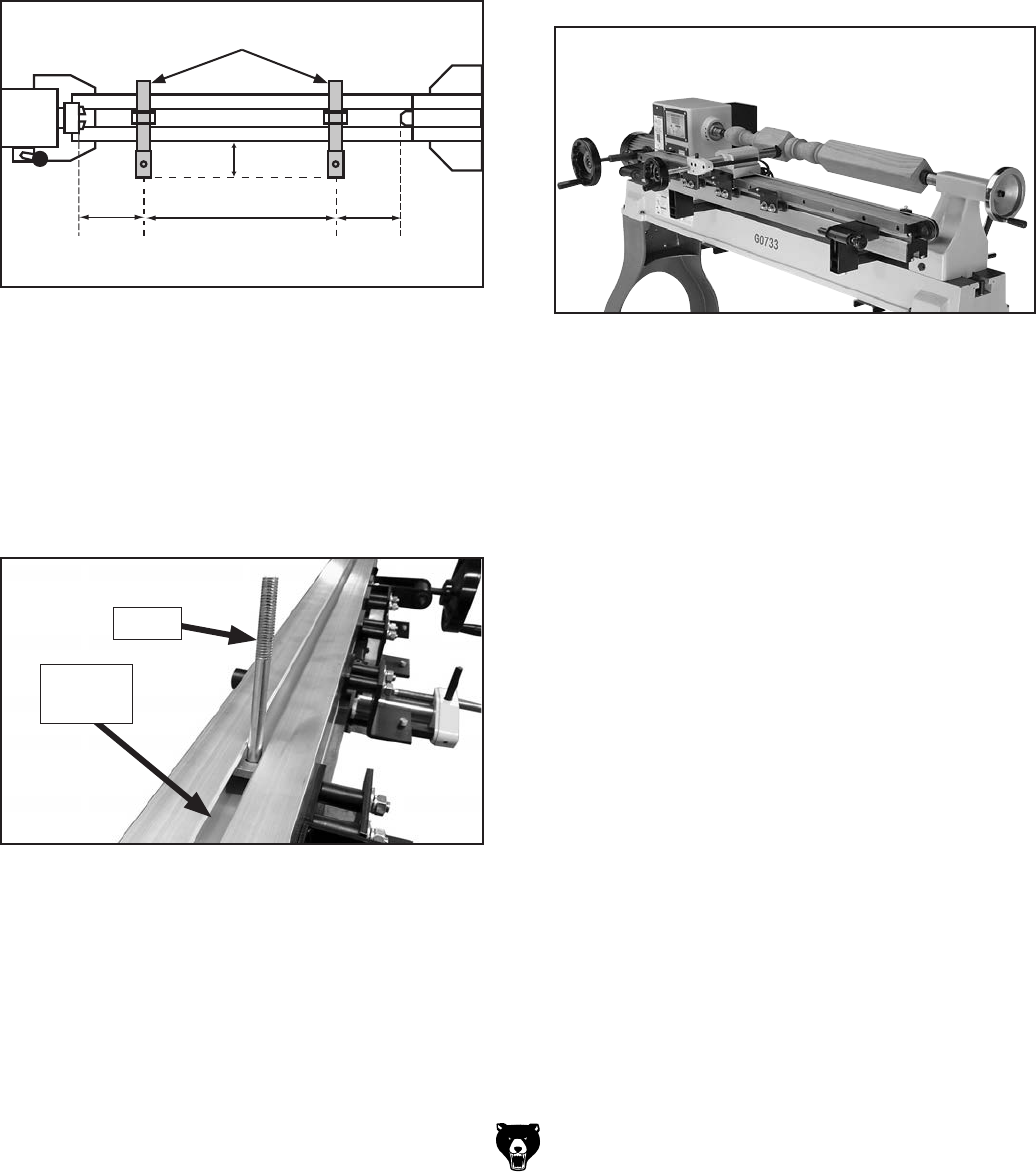

3. Adjust support arm assemblies so they are

centered on points measuring 20% of dis-

tance across lathe bed from headstock to

tailstock (see Figure 7). Front of support

arms should extend beyond front of lathe bed

by about 6".

— Some minor degree of variation may be

necessary to eliminate any interference to

normal operation of lathe.

4. Tip copy attachment upside down so bot-

tom channel is facing upwards, then slide

(2) M10-1.5 x 100 T-bolts into channel (see

Figure 8).

— If using short support arms, use (2) M10-

1.5 x 45 T-bolts.

6. Mount copy attachment so tool will reach cor-

rect starting point for desired cut.

7. Install (2) 10mm flat washers and (2) M10-

1.5 hex nuts onto T-bolts installed in Step 4.

Then tighten support arm assembly knobs.

— Make certain copy attachment does not

block access to lathe controls. Some lat-

eral adjustment can be made to assure

clearance if necessary (see Figure 9).

Figure 8. T-bolt installed into slot on bottom of

copy attachment (1 of 2).

T-Bolt

T-Bolt

Channel

5. Turn copy attachment right side up, then

insert T-bolts into support arm holes.

Figure 9. Example of copy attachment mounted

on lathe without obstructing lathe controls.

8. Congratulations, your copy attachment has

been successfully installed. It must now be

aligned for parallelism. Please proceed to

Rough Alignment on Page 12.

Figure 7. Attachment locations for support arms.

6"

20%

60%

20%

Support Arms