-22-

Model T27313 (Mfd. Since 01/15)

Ca ble Tensio n

The movement of the carriage assembly along

the body of the copy attachment is controlled by

the movement of the longitudinal-feed handwheel.

This handwheel is connected to the carriage via a

cable. This cable should be taut to ensure respon-

sive movement from the carriage.

Tools Needed Qty

Open-End Wrench 13mm .................................. 2

To adjust cable tension:

1. DISCONNECT MACHINE FROM POWER!

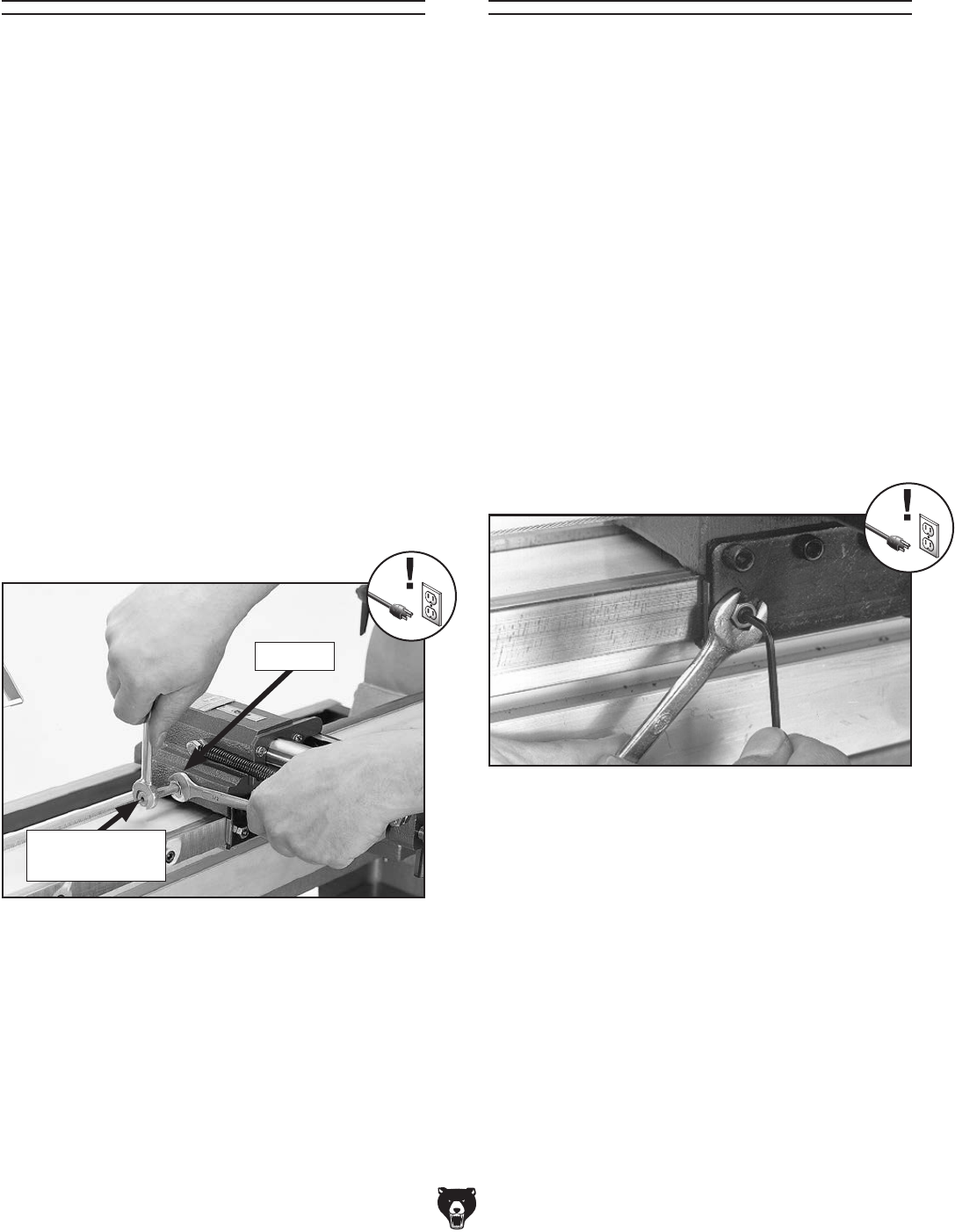

2. Loosen hex nut shown in Figure 25.

3. Adjust tension by loosening or tightening

cable tension bolt (see Figure 25).

Note: Cable should be pulled snug, but not

so tight that stress is placed on cable.

4. Tighten hex nut (see Figure 25).

Gib Adjustment

Figure 26. Adjusting carriage gib (1 of 8).

The goal of gib adjustment is to remove sloppi-

ness or "play" between the carriage and the bed

while still allowing free movement of the carriage.

There are eight adjustment locations: two on the

front of the carriage, two on the back and four

underneath.

Tools Needed Qty

Hex Wrench 2.5mm ........................................... 1

Open-Ended Wrench 8mm ............................... 1

To adjust gibs:

1. DISCONNECT MACHINE FROM POWER!

2. Loosen hex nut shown in Figure 26.

3. Adjust set screws to increase or decrease

friction (see Figure 26).

Figure 25. Adjusting carriage cable tension.

Cable Tension

Bolt

4. Slide carriage back and forth to test for bind-

ing or wobble.

—If carriage binds or wobbles, repeat Step 3.

5. When adjustments are complete, tighten the

hex nuts while maintaining the set screw

position.

Hex Nut