-18-

Model T27313 (Mfd. Since 01/15)

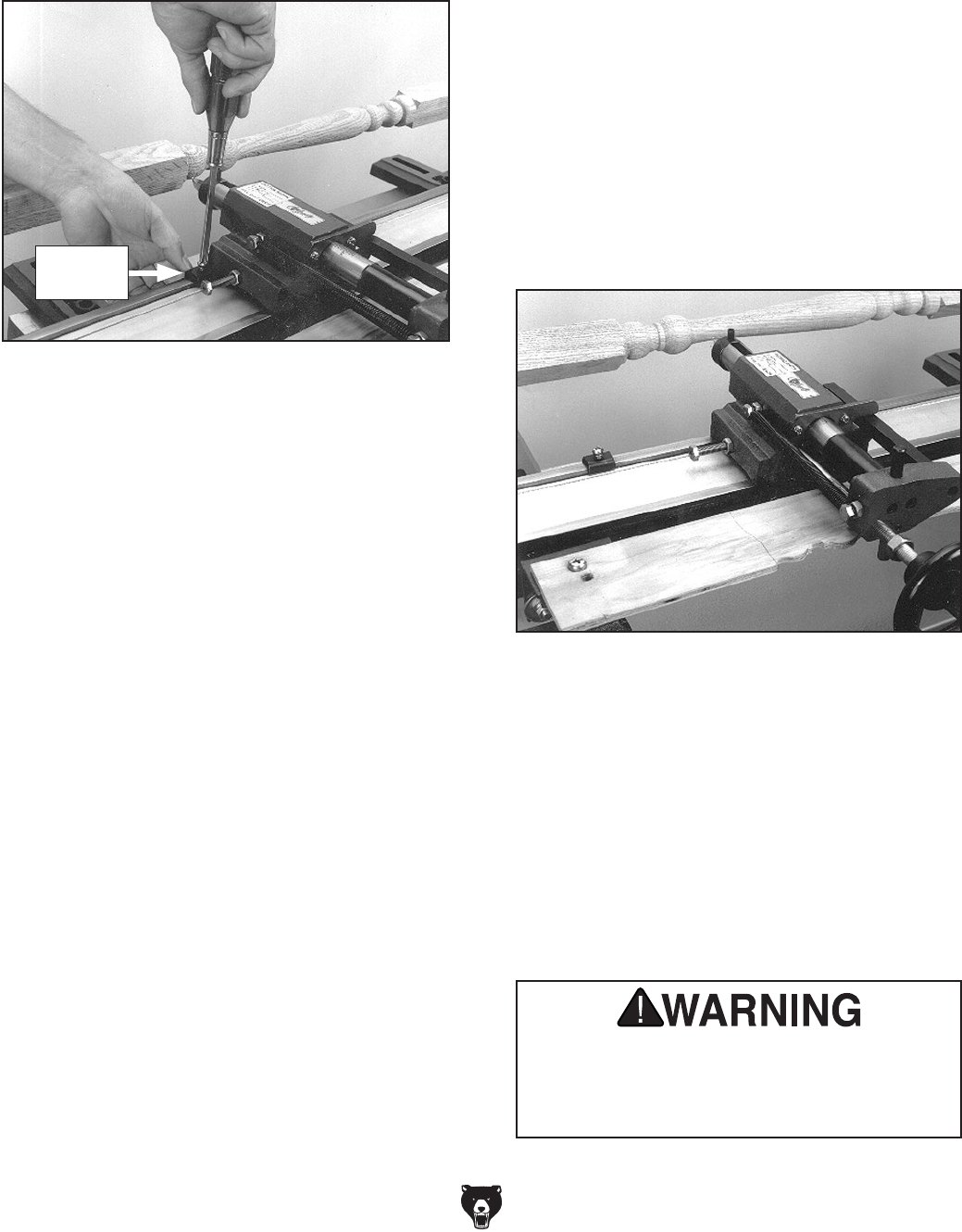

Figure 20. Shaping the copy spindle.

15. After completing initial copy, continue follow-

ing Steps 1–14 until all spindles are com-

pleted.

16. When all spindles are complete, remove copy

attachment and replace it with the lathe tool

post.

17. Use appropriate lathe chisels to sharpen

details and smooth turned surfaces of each

copy, then sand smooth.

12. Turn lathe OFF and inspect results.

—If workpiece is tapered, copy attachment

is not properly aligned to wood lathe (refer

to Performing Final Alignment on Page

13).

13. If you are satisfied, continue to remove mate-

rial from workpiece, using “downhill” cutting

method illustrated in Figure 17 on Page 17.

Tip: Avoid cutting “uphill”. It will likely result in

chipping and gouging.

14. Continue removing stock until workpiece is

complete (see Figure 20).

7. Repeat procedure for right hand stop.

8. Adjust cutting tool so both it and stylus are

just touching workpiece and template.

—It is essential for accurate copying that

cutting tool tip and stylus always remain at

same positions in relation to workpiece and

template.

9. Slide carriage away from workpiece, so sty-

lus and cutter are clear of workpiece and

template.

10. Turn lathe ON at its slowest speed, then

slowly advance cutting tool toward left edge

of workpiece. Once contact is made, advance

cutting tool into copy spindle approximately

1

⁄16". Turn longitudinal handwheel so the car-

riage travels from left to right.

11. After each pass, extend cutting tool another

1

⁄16" (maximum), and repeat with another

pass. Repeat this process until stylus comes

in contact with template.

—If cutting tool tends to bite or gouge

workpiece, back off cutting tool slightly and

try again. Be conservative when removing

stock.

6. Move carriage stylus to left hand limit of pro-

filed area and adjust left hand carriage stop

until it contacts carriage, then tighten stop

(see Figure 19).

Figure 19. Adjusting carriage stops.

Carriage

Stop

Refer to your owner's manual for complete

setup, operating, and safety instructions.

Serious injury could occur if you do not fol-

low these instructions.