-20-

Model T27313 (Mfd. Since 01/15)

SECTION 5: MAINTENANCE

For optimum performance from your machine,

follow this maintenance schedule and refer to any

specific instructions given in this section.

Daily Check

• Loose mounting bolts.

• Worn or damaged wires.

• Any other unsafe condition.

Monthly Check

• feed cable tension, damage, or wear.

• Clean/vacuum dust buildup.

Schedule

To reduce risk of shock or

accidental startup, always

disconnect machine from

power before adjustments,

maintenance, or service.

Cleaning the Model T27313 is relatively easy.

Vacuum excess wood chips and sawdust, and

wipe off the remaining dust with a dry cloth. If any

resin has built up, use a resin dissolving cleaner

to remove it.

Protect any unpainted cast iron surfaces by wip-

ing it clean after every use—this ensures moisture

from wood dust does not remain on bare metal

surfaces. Keep cast iron surfaces rust-free with

regular applications of products like G96

®

Gun

Treatment, SLIPIT

®

, or Boeshield

®

T-9 (see Page

19 for more details).

Cleaning &

Protecting

Lubrication

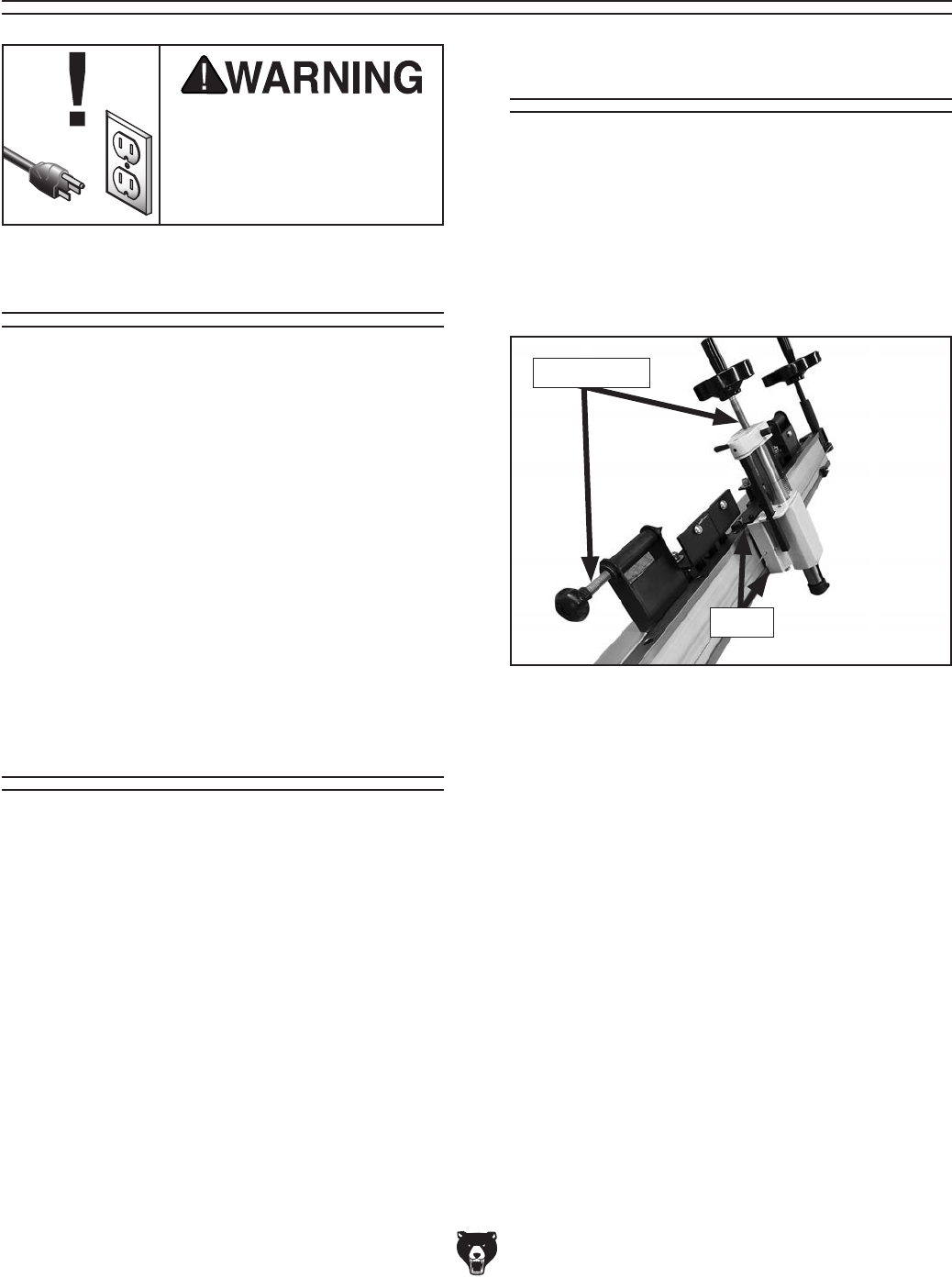

Leadscrews and Slides

Lubrication Type ...T23964 or NLGI#2 Equivalent

Amount .............................................. 1–2 Pumps

Lubrication Frequency .....................6–12 Months

Add lubrication to the leadscrews and slides

shown in Figure 24.

Figure 24. Location of leadscrews and slides.

Leadscrews

Slides