SKU 93762 For technical questions, please call 1-800-444-3353. Page 19

Adjusting The Blade Guide Bearings:

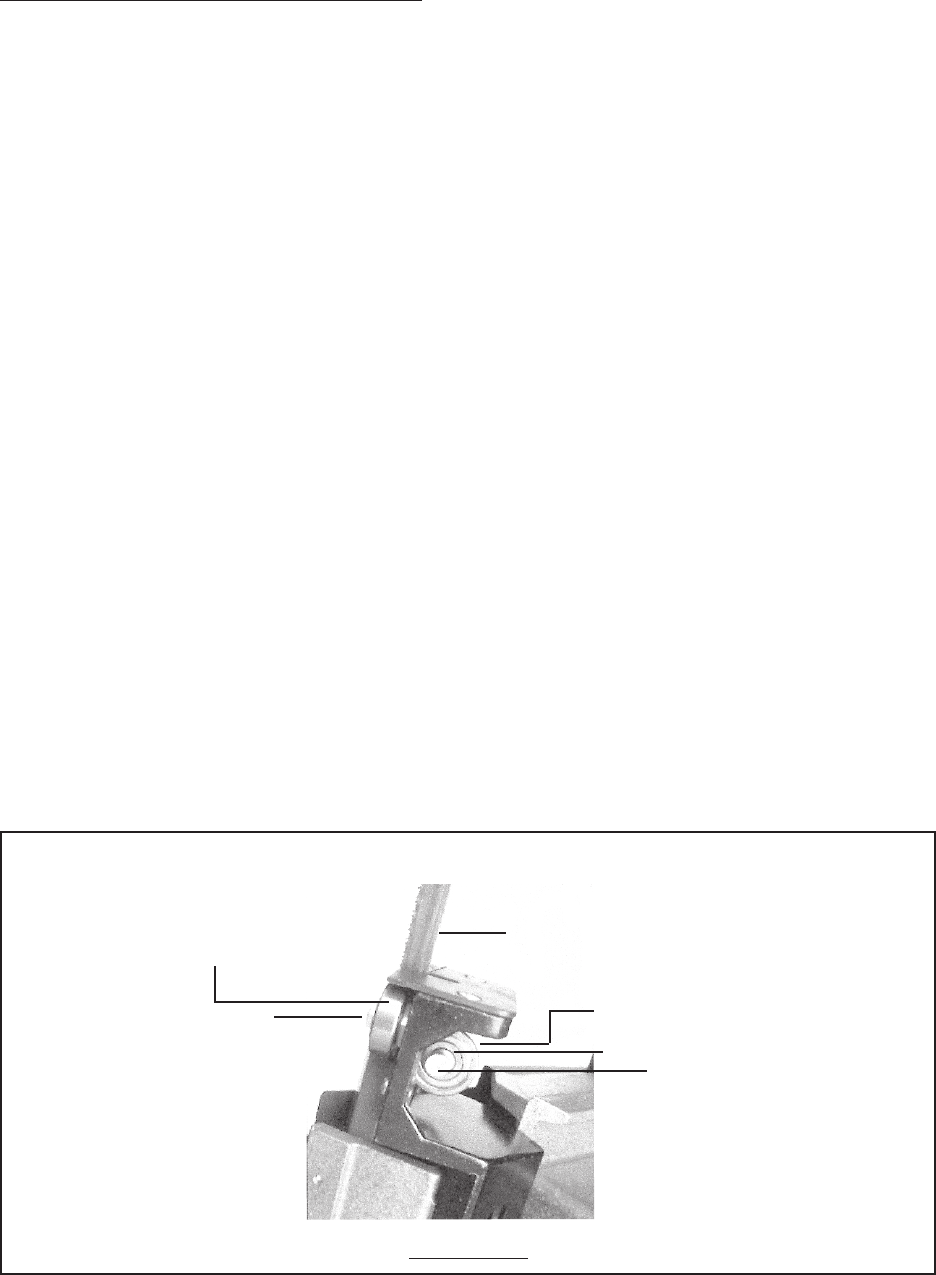

1. NOTE: Blade Guide Bearings (88, 92, 100, 104) adjustment is a critical factor in

the performance of the Bandsaw.

2. It is always best to try a new Saw Blade (82) to see if it will correct poor cutting

before attempting to adjust the Blade Guide Bearings. For example, if a Saw

Blade becomes dull on one side sooner than the other, it will begin cutting

crooked. A Saw Blade replacement will correct this problem, whereas Blade

Guide Bearings adjustment will not.

3. If a new Saw Blade does not correct the problem, check the Blade Adjustable

Seats (83, 110) to obtain the proper clearance. (See Figure S.)

4. NOTE: There should be from .000” (just touching) to .001” clearance between

the Saw Blade and Blade Guide Bearings (88, 92, 100, 104). To obtain this

clearance adjust as follows:

A. The

Outer

Blade Guide Bearings (92, 104) are mounted to Shafts (91, 103)

and can be adjusted. (See Figure S.)

B. Loosen the Nuts (86, 96) while holding the Shafts (91, 103) with an Allen

wrench (not included). (See Figure S.)

C. Position the Shafts (91, 103) by turning it to the desired position of clear-

ance. Then, re-tighten the Nuts (86, 96). (See Figure S.)

D. Adjust the

Inner

Blade Guide Bearings (88, 100) in the same manner.

SHAFT (91, 103)

OUTER BLADE GUIDE BEARING

(92, 104)

INNER BLADE GUIDE BEARING (88, 100)

NUT (86, 96)

(NOT SHOWN)

SHAFT (91, 103)

SAW BLADE (82)

FIGURE S