11

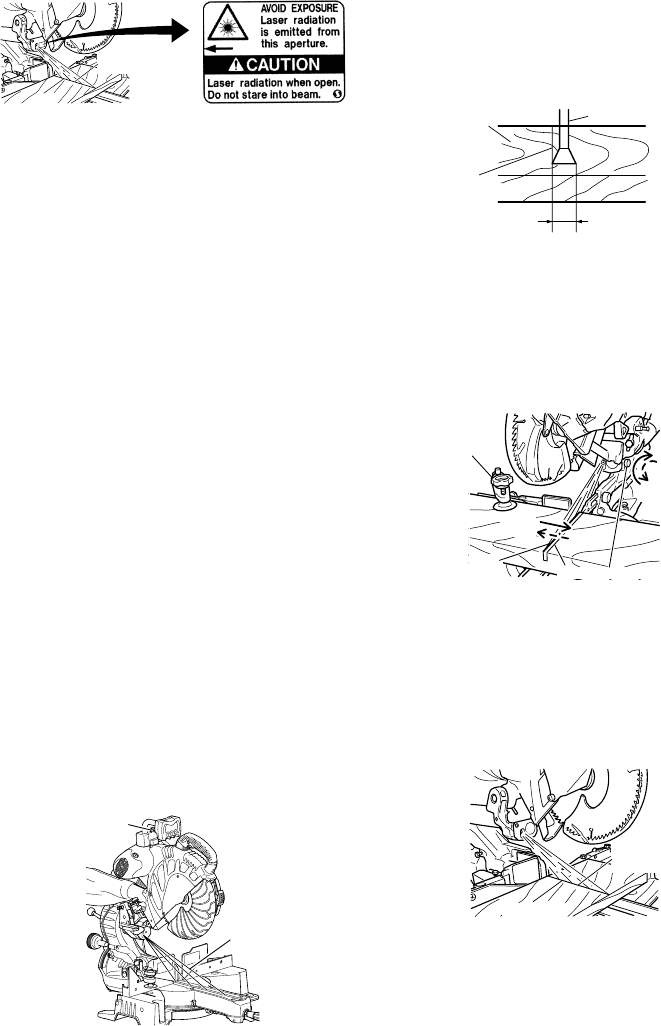

Fig. 19

* Laser radiation- Do not stare into beam.

* Laser radiation on work table. Do not stare into beam.

If your eye is exposed directly to the laser beam, it

can be hurt.

* Do not dismantle it.

* Do not give strong impact to the laser marker (main

body of tool); otherwise, the position of a laser line

can go out of order, resulting in the damage of the

laser marker as well as a shortened service life.

* Keep the laser marker lit only during a cutting

operation. Prolonged lighting of the laser marker can

result in a shortened service life.

* Use of controls or adjustments or performance of

procedures other than those specified herein may

result in hazardous radiation exposure.

NOTE

* Perform cutting by overlapping the ink line with the

laser line.

* When the ink line and the laser line are overlapped,

the strength and weakness of light will change,

resulting in a stable cutting operation because you

can easily discern the conformity of lines. This ensures

the minimum cutting errors.

* In outdoor or near-the-window operations, it may

become difficult to observe the laser line due to the

sunlight. Under such circumstances, move to a place

that is not directly under the sunlight and engage in

the operation.

* Do not tug on the cord behind the motor head or hook

your finger, wood and the like around it; otherwise,

the cord may come off and the laser marker may not

be lit up.

Ink lining can be easily made on this tool to the laser

marker. A switch lights up the laser marker. (Fig. 20)

Depending upon your cutting choice, the laser line

can be aligned with the left side of the cutting width

(saw blade) or the ink line on the right side.

The laser line is adjusted to the width of the saw blade

at the time of factory shipment. Adjust the positions

of the saw blade and the laser line taking the following

steps to suit the use of your choice.

Fig. 20

(1) Light up the laser marker and make a groove of about

5 mm deep on the workpiece that is about 20 mm in

height and 150 mm in width. Hold the grooved

workpiece by vise as it is and do not move it. For

grooving work, refer to “13.Groove cutting

procedures” on page 19.

Fig. 21

(2) Then, turn the adjuster and shift the laser line. (If you

turn the adjuster clockwise, the laser line will shift to

the right and if you turn it counterclockwise, the laser

line will shift to the left.) When you work with the ink

line aligned with the left side of the saw blade, align

the laser line with the left end of the groove. (Fig. 22)

When you align it with the right side of the saw blade,

align the laser line with the right side of the groove.

Fig. 22

(3) After adjusting the position of the laser line, draw a

right-angle ink line on the workpiece and align the

ink line with the laser line. When aligning the ink line,

slide the workpiece little by little and secure it by vise

at a position where the laser line overlaps with the

ink line. Work on the grooving again and check the

position of the laser line. If you wish to change the

laser line's position, make adjustments again

following the steps from (1) to (3).

Fig. 23

Switch

Laser line

Saw blade

Marking

(pre-marked)

Workpiece

Cutting width

Vise assembly

Turn

Move

Laser line

Groove

Adjuster

Marking

(pre-marked)

Laser line

03Eng_C12LSH_Eng 4/26/07, 5:32 PM11