16

(2) Re-tighten the side handle to secure the turntable in

the desired position.

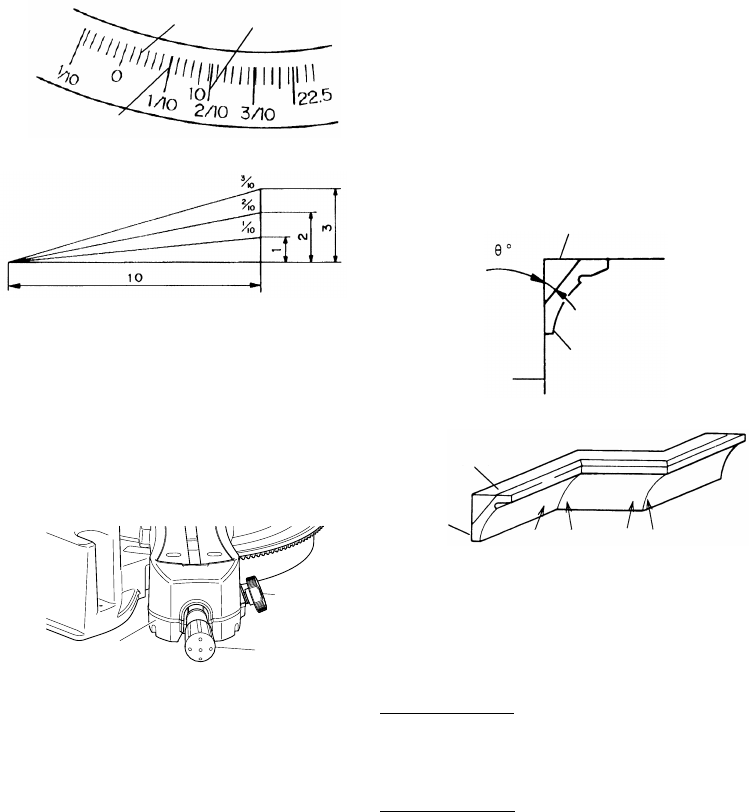

(3) The miter scale (Fig. 37) indicates both the cutting angle

on the angle scale and the gradient on the grade scale.

(4) The gradient, which is the ratio of the height to the

base of the triangular section to be removed, may be

used for setting the miter scale instead of the cutting

angle, if desired (see Fig. 37).

(5) Therefore, to cut a workpiece at a grade of 2/10, set

the indicator to position a as indicated in Fig. 37.

Fig. 37

Fig. 38

NOTE

* Positive stops are provided at the right and left of the

0° center setting, at 15°, 22.5°, 31.6° and 45° settings.

Check that the miter scale and the tip of the indicator

are properly aligned.

* Operation of the saw with the miter scale and indicator

out of alignment, or with the side handle not properly

tightened, will result in poor cutting precision.

10. Miter angle fine adjustment

(1) Rotate the turntable to the miter angle you need.

(2) When making fine adjustments of the miter angle, turn

the knob (A) while pulling up the lever (Fig. 39).

Fig. 39

NOTE

Turning knob (A) clockwise, allows fine adjustment

of the turntable to the right. Turning knob (A)

counterclockwise, allows fine adjustment of the

turntable to the left.

(3) After adjusting to the desired angle, tighten the side

handle.

CAUTION

Always check that the side handle is secured and the

turntable is clamped.

If you attempt angle cutting without clamping the

turntable, then the turntable might shift unexpectedly

causing injuries.

Angle scale

Grade scale

a

Miter scale

11. Compound cutting procedures

Compound cutting can be performed by following the

instructions in 7 and 10 above. For maximum

dimensions for compound cutting, refer to

“SPECIFICATIONS” table on page 5.

CAUTION

Always secure the workpiece with the right or left hand

and cut it by sliding the round portion of the saw

backwards with the left hand.

It is very dangerous to rotate the turntable to the left

during compound cutting because the saw blade may

come into contact with the hand that is securing the

workpiece.

In case of compound cutting (angle + bevel) by left

bevel, turn the sub-fence (B) counterclockwise, and

engage in the cutting operation.

In case of compound cutting (angle + bevel) by right

bevel, turn the sub-fence (A) clockwise, and engage

in the cutting operation.

12. Crown molding cutting procedures

Fig. 40 shows two common crown molding types

having angles of (q) 38° and 45°.

For the typical crown molding fittings, see Fig. 41.

Fig. 40

Fig. 41

The table below shows the miter angle and the bevel

angle settings that are ideal for the two crown molding

types.

NOTE

For convenience, positive stops are provided for the

miter setting (left and right 31.6°) positions.

For miter cut setting

If the turntable has been set to either of the angles

described, move the turntable adjusting side handle

a little to the right and left to stabilize the position

and to properly align the miter angle scale and the tip

of the indicator before the operation starts.

For bevel cut setting

Turn the clamp lever on bevel section to the left and

check that the position is stable and that the bevel

angle scale and the tip of the indicator are properly

aligned. Then tighten the clamp lever.

Wall

A Upper surface ceiling

B Lower surface

Turntable

Side handle

Knob (A)

Ceiling

Wall

1

2

34

Inside corner Outside corner

03Eng_C12LSH_Eng 4/26/07, 5:32 PM16