7

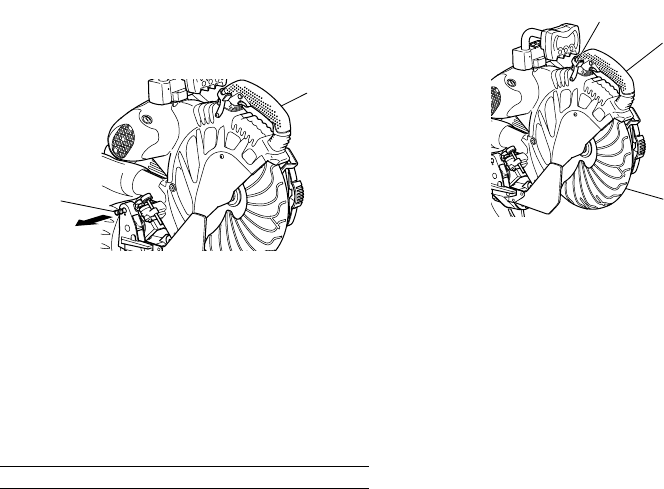

2. Releasing the locking pin

When the power tool is prepared for shipping, its main

parts are secured by a locking pin.

Move the handle slightly so that the locking pin can

be disengaged.

Fig. 6

NOTE

Lowering the handle slightly will enable you to

disengage the locking pin more easily and safely.

The lock position of the locking pin is for carrying and

storage only.

3. Installing the dust bag, holder, stopper and vises

(The holder and stopper are optional accessories.)

Attach the dust bag and vise assembly as indicated

in Fig. 1 and Fig. 2.

BEFORE USING

1. Make sure the power source is appropriate for the

tool.

WARNING

Never connect the power tool unless the available AC

power source is of the same voltage as that specified

on the nameplate of the tool.

Never connect this power tool to a DC power source.

2. Make sure the trigger switch is turned OFF.

WARNING

If the power cord is connected to the power source

with the trigger switch turned ON the power tool will

start suddenly and can cause a serious accident.

3. Check the saw blade for visible defects.

Confirm that the saw blade is free of cracks or other

visible damage.

4. Confirm that the saw blade is attached securely to

the power tool.

Using the supplied 17 mm box wrench, tighten the

10 mm bolt on the saw blade spindle to secure the

saw blade.

For details, see Fig. 55-a, Fig. 55-b, Fig. 55-c and Fig.

55-d in the section on “SAW BLADE MOUNTING AND

DISMOUNTING”.

5. Check to see that the lower guard operates smoothly

CAUTION

This slide compound miter saw is equipped with a

saw head lock as safety device.

To lower the saw head to cut, the lock must be released

by pressing the lever (A) with your thumb.

(1) When you push down the handle while pushing the

lever (A), check that the lower guard revolves

smoothly (Fig. 7).

Pull

Locking pin

Handle

Lower guard

Fig. 7

6. Confirm the position of the spindle lock before using

the tool.

After installing the saw blade, confirm that the spindle

lock has been returned to the retract position before

using the power tool (see Fig. 2).

7. Check the lower limit position of the Saw Blade.

Although it was adjusted before shipment, carefully

check the height of the saw blade. Confirm that the

saw blade can be lowered 9 mm to 11 mm below the

table insert. For details, see the section on “Checking

the saw blade lower limit position”.

8. Check the Power Receptacle.

To prevent overheating, accidental stopping or

intermittent operation, confirm that the power cord

plug fits properly in the electrical receptacle and does

not fall out after it is inserted. Repair or replace the

receptacle if it is faulty.

9. Confirm the tool’s power cord is not damaged.

Repair or replace the power cord if an inspection

indicates that it is damaged

AFTER CONNECTING THE POWER PLUG TO AN AP-

PROPRIATE AC POWER SOURCE, CHECK THE OPERA-

TION OF THE TOOL AS FOLLOWS:

10. Trial Run

After confirming that no one is standing behind, the

power tool start and confirm that no operating

abnormalities exist before attempting a cutting

operation.

11. Inspect the rotating stability of the saw blade.

For precise cutting, rotate the saw blade and check

for deflection to confirm that the blade is not

noticeably unstable; otherwise vibrations might occur

and cause an accident.

Lever (A)

(2) Next, check that the lower guard returns to the original

position when the handle is raised.

Handle

03Eng_C12LSH_Eng 4/26/07, 5:32 PM7