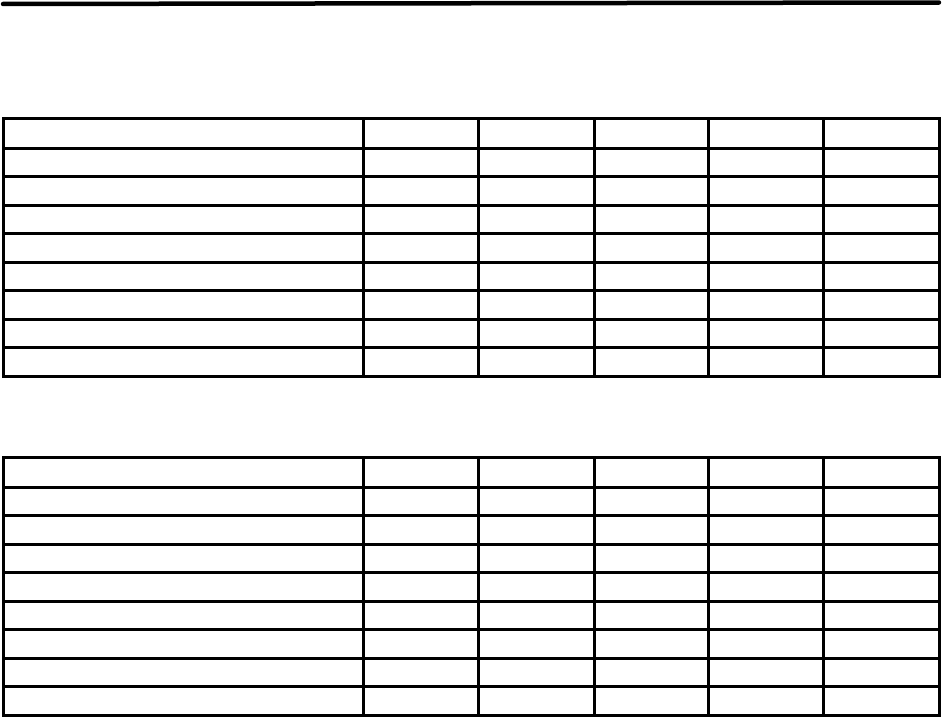

6-18 Sample Materials

MELAMINE - PHOTO/CLIPART ENGRAVING

RASTER ENGRAVING

LASER WATTAGE POWER SPEED PPI PASS DEPTH

15 80 30 500 1 .008”

20 80 40 500 1 .008”

25 80 50 500 1 .008”

30 80 60 500 1 .008”

35 80 70 500 1 .008”

40 80 80 500 1 .008”

45 80 90 500 1 .008”

50 80 100 500 1 .008”

COMMENTS: Engrave unmasked. Use a resolution of 500 DPI.

RASTER ENGRAVING

LASER WATTAGE POWER SPEED PPI PASS DEPTH

15 80 15 500 1 .008”

20 80 20 500 1 .008”

25 80 25 500 1 .008”

30 80 30 500 1 .008”

35 80 35 500 1 .008”

40 80 40 500 1 .008”

45 80 45 500 1 .008”

50 80 50 500 1 .008”

COMMENTS: Engrave unmasked. Use a resolution of 250 DPI.

COMMENTS

Engraving photographs can be challenging at first but becomes easier once there is an

understanding of what to look for and how to achieve the desired results. In an image

processing software, scan the image in at 300 DPI. Adjust the brightness and the contrasts to

brighten the light colors and darken the dark colors. The photo might look better by using a

sharpening filter to sharpen up the image slightly. The next step is to select a halftone pattern.

Usually, imaging software gives the choice of using different halftone patterns including

frequency of lines per inch and pattern angles. Use a line frequency above 20 and below 100.

The size of the dots decreases as the line frequency increases. Experiment to see which

pattern looks the best. Big dots look good on some materials and small dots look better on

others. If it is not possible to assign a halftone pattern in the imaging software, the printer driver

will automatically default to a predetermined pattern based on RESOLUTION. When using the

Clipart mode switch, which prints all Clipart or drawings as grayscale bitmaps, use the same

parameters and techniques as for engraving photographs. Please refer to Section 3 about using

predefined halftone screens in the driver or creating custom ones.