MAINTENANCE

33

enhttp://air.ingersollrand.com

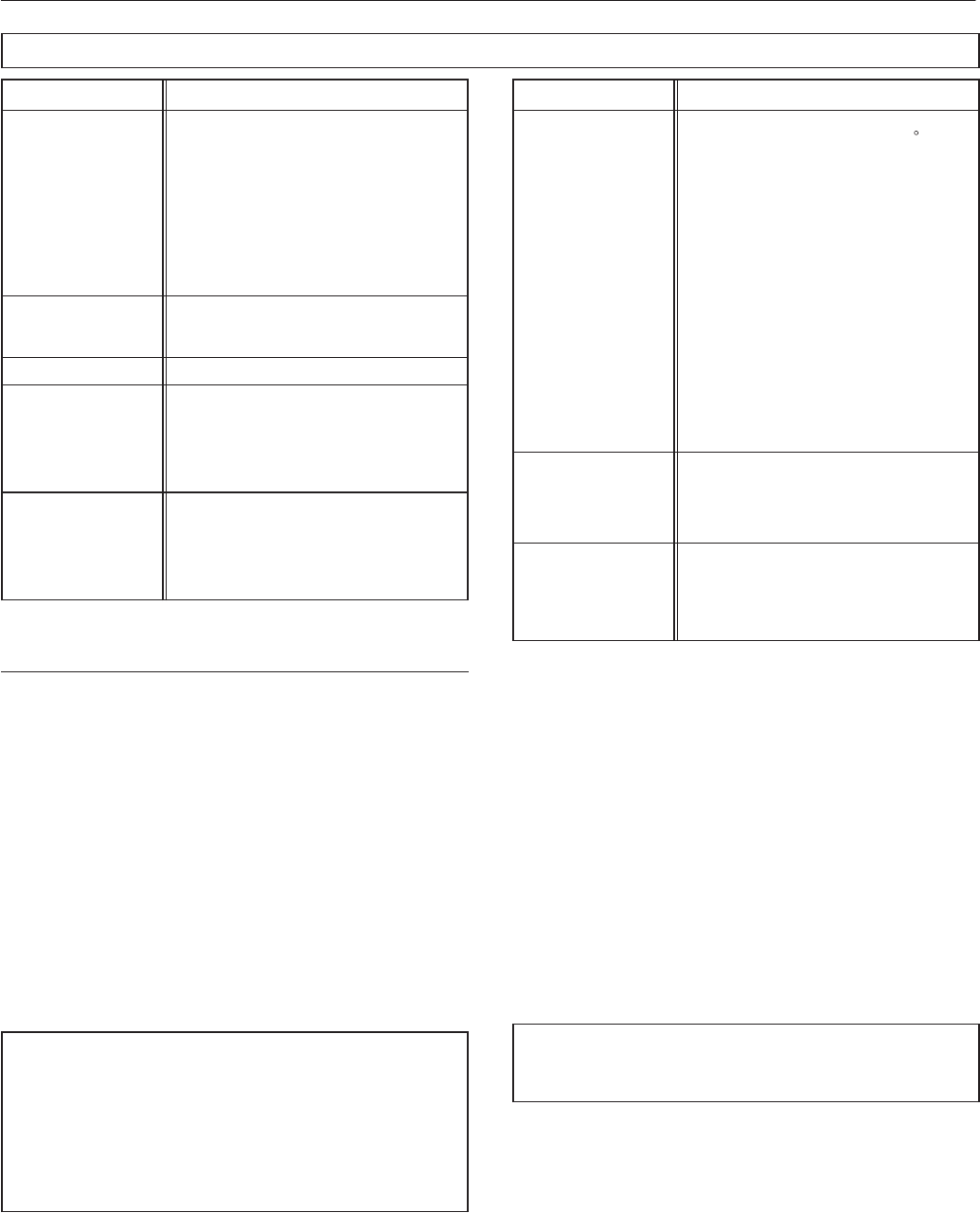

Maintenance Schedule

PERIOD MAINTENANCE

Each 24 hours

operation

Check the coolant level and replenish if

necessary.

Visual check of

machine for any

leaks, dust build up

or unusual noise or

vibration

Report immediately, contact Ingersoll Rand

authorized distributor for assistance if in

doubt

When compressor

is receiver mounted

Drain air receiver of condensate, or check

that automatic drain is operating

Visual check

condition of

package pre −lter

Blow clean if needed

First 150 hours Change the coolant lter.

Each month or 100

hours

Remove and clean package pre −lter,

replace if needed

Check the cooler(s) for build up of foreign

matter. Clean if necessary by blowing out

with air or by pressure washing.

Every 4 months

CONDENSER

Remove any dust from the condenser ns.

COMPRESSOR

Make sure compressor power consumption

complies with data plate specications.

PERIOD MAINTENANCE

Each year or

2000 hours

Check the operation of the high

temperature protection switch (109 C).

Change the coolant lter.

Check scavenge orice for blockage, clean

if required.

Replace elements in IRGP and IRHE

lters.

Change the separator cartridge.

Check motors w/grease ttings - grease

bearings per motor data plate.

Change the Air Filter element.

Take coolant sample for uid analysis.

Change the package pre −lter.

CONDENSATE DRAINS

Completely disassemble the drains and

clean all their components.

Every two years or

8000 hours

Replace the Ultra Coolant at

whichever interval occurs rst.

Check and replace all items included within

2000 hour service

Every 4 years or

16000 hours

Replace sealed bearing without grease ttings

on motors.

18000 hours

Fit replacement electrical contactor tips.

Strip, clean and regrease or replace motor

bearings on motors with grease ttings.

ROUTINE MAINTENANCE

This section refers to the various components which require

periodic maintenance and replacement.

. It should be noted that the intervals between service requirement

may be signicantly reduced as a consequence of poor operating

environment. This would include ef fects of atmospheric contamination

and extremes of temperature.

The SERVICE/MAINTENANCE CHART indicates the various

components’ descriptions and the intervals when maintenance has to

take place. Oil capacities, etc., can be found in the GENERAL

INFORMATION section of this manual.

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

CAUTION: Before beginning any work on the compressor, open,

lock and tag the main electrical disconnect and close the isolation

valve on the compressor discharge. Vent pressure from the unit

by slowly unscrewing the coolant ll cap one turn. Unscrewing

the ll cap opens a vent hole, drilled in the cap, allowing pressure

to release to atmosphere. Do not remove the ll cap until all

pressure has vented from the unit. Also vent piping by slightly

opening the drain valve. When opening the drain valve or the

coolant ll cap, stand clear of the valve discharge and wear

appropriate eye protection.

Ensure that maintenance personnel are properly trained,

competent and have read the Maintenance Manuals.

Prior to attempting any maintenance work, ensure that: −

. all air pressure is fully discharged and isolated from the system. If

the automatic blowdown valve is used for this purpose, then allow

enough time for it to complete the oper ation.

. the machine cannot be started accidentally or otherwise.

. all residual electrical power sources (mains and battery) are

isolated.

Prior to opening or removing panels or covers to work inside

a machine, ensure that: −

. anyone entering the machine is aware of the reduced level of

protection and the additional hazards, including hot surfaces and

intermittently moving parts.

. the machine cannot be started accidentally or otherwise.

Prior to attempting any maintenance work on a running

machine, ensure that: −

DANGER

Only properly trained and competent persons should

undertake any maintenance tasks with the compressor running or

with electrical power connected.

. the work carried out is limited to only those tasks which require the

machine to run.

. the work carried out with safety protection devices disabled or

removed is limited to only those tasks which require the machine to be

running with safety protection devices disabled or removed.

. all hazards present are known (e.g. pressurised components,

electrically live components, removed panels, covers and guards,

extreme temperatures, inow and outow of air, intermittently moving

parts, safety valve discharge etc.).

. appropriate personal protective equipment is worn.