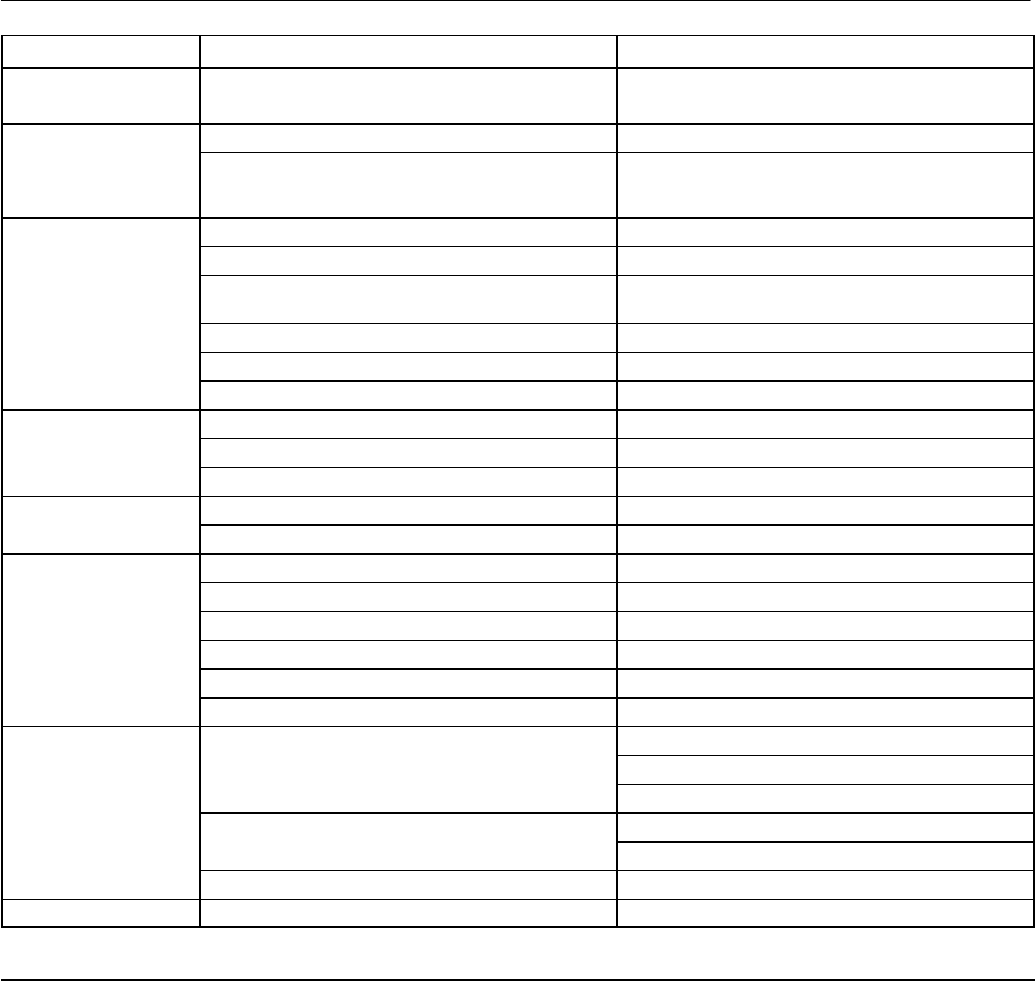

TROUBLE SHOOTING

37

enhttp://air.ingersollrand.com

PROBLEM CAUSE REMEDY

Compressor fails to

start

Mains power or Control voltage not available. § Check incoming power supply.

§ Check the control circuit fuse.

Machine shuts down

periodically and

High airend temperature. Top up coolant.

periodically and

indicates a fault

condition

Line voltage variation out of range. § Ensure voltage is correctly between operating limits

and that no voltage spikes are being introduced into

the supply by external equipment or power feed.

High current draw Compressor operating above rated pressure. Set pressure to correct rating for machine.

Separator cartridge contaminated. Change air filter, and separator cartridge.

Low voltage. § Ensure voltage does not drop below 10% on start up

and 6% running.

Unbalanced voltage. Correct incoming supply voltage.

Damaged airend. † Change Airend.

Compressed air filter(s) contaminated. Replace air filter(s).

Low current draw Air filter contaminated. Change air filter.

Compressor operating unloaded. Set pressure to correct rating for machine.

High voltage. Reduce site voltage to correct operating voltage.

High discharge

pressure

Defective or incorrect pressure switch setting. Replace or set pressure to correct rating for machine.

pressure

Inlet valve malfunction. † Fit inlet valve service kit.

Low system air

pressure

Separator cartridge contaminated. Fit new Separator cartridge.

pressure

Incorrect pressure transducer setting Set pressure to correct rating for machine.

Minimum pressure valve malfunction. † Fit Minimum pressure valve service kit.

Air system leaks. † Fix leaks.

Inlet valve malfunction. † Fit inlet valve service kit.

System demand exceeds compressor delivery. Reduce demand or install additional compressor.

High dewpoint Refrigeration compressor not supplied power. Check incoming power supply.

Check the dryer protection fuse.

Check auxiliary contact on main motor contactor.

Condensate system malfunction. Check operation of drain valve.

Check operation of condensate check valves.

Condenser dirty. Clean condenser and replace panel filter element.

Ice formation in dryer Low evaporator pressure. Check hot gas valve setting.

NOTES:

§ Must be carried out by a competent electrician.

† This work is recommended to be carried out only by an Ingersoll Rand authorized service technician.