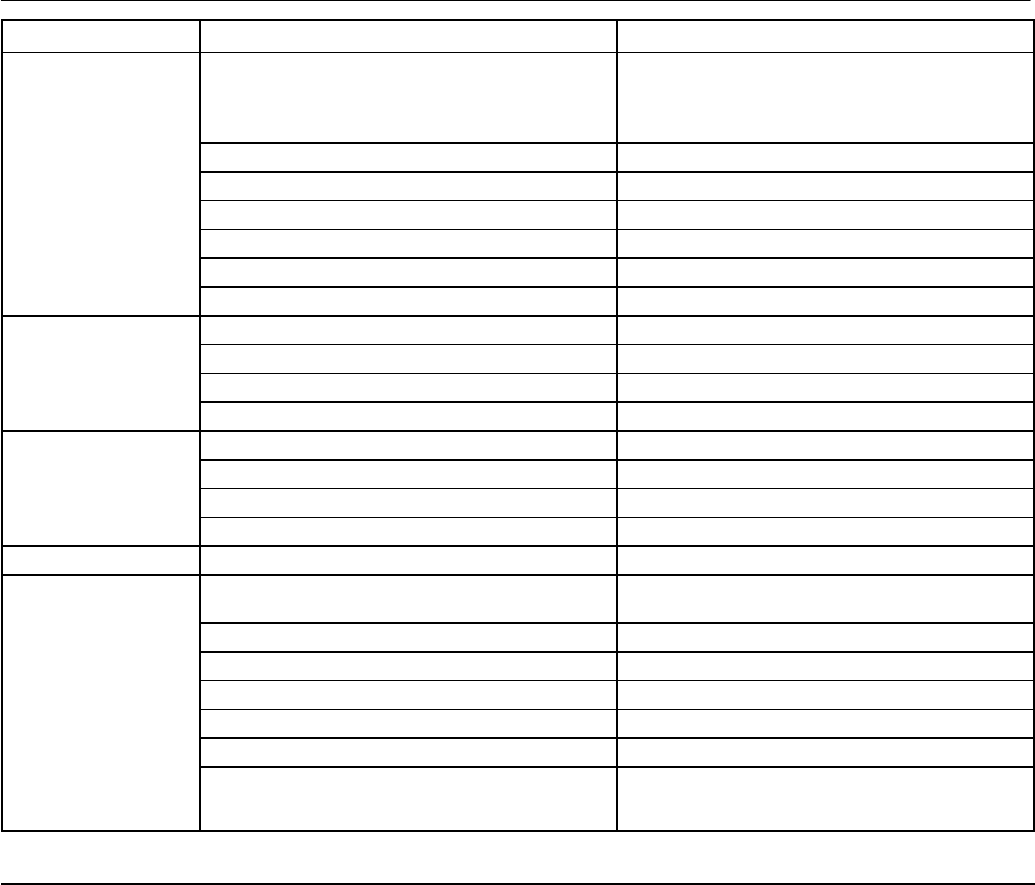

TROUBLE SHOOTING

38

PROBLEM CAUSE REMEDY

Compressor trips due to

over temperature

Compressor module operating above rated pressure.

Set pressure to correct rating for machine.

1. Blocked filters

2. Blocked separator cartridge

3. Restricted air fow through dryer

Package pre−filter blocked. Clean / replace package pre−filter.

Cooler blocked. Clean cooler.

Missing or incorrectly fitted enclosure panels Ensure that all enclosure panels are correctly fitted

Low coolant level. Top up coolant and check for leaks.

High ambient temperature. Re−site compressor.

Restricted cooling air flow. Ensure correct air flow to compressor.

Excessive coolant

consumption

Separator cartridge leak. Fit new Separator cartridge.

consumption

Blocked separator cartridge drain. † Remove fittings and clean.

Compressor operating below rated pressure. Set pressure to correct rating for machine.

Coolant system leak. † Fix leaks.

Excessive noise level Air system leaks. † Fix leaks.

Airend defective. † Change Airend.

Motor defective. † Replace motor.

Loose components. † Retighten loose items.

Shaft seal leaking Defective shaft seal. † Fit Airend shaft seal kit.

Pressure relief valve

opens

Defective transducer or incorrect pressure transducer

setting

Replace or set pressure to correct rating for machine.

Minimum pressure valve malfunction. † Fit Minimum pressure valve service kit.

Inlet valve malfunction. † Fit inlet valve service kit.

Compressed air filter(s) contaminated. Replace air filter(s).

Blocked separator cartridge Clean / replace separator cartridge.

Blocked compressed air filters Clean / replace compressed air filters.

Frozen condensate in dryer Check hot gas bypass valve.

Ensure ambient temperature is greater than 35_F

(2_C).

NOTES:

§ Must be carried out by a competent electrician.

† This work is recommended to be carried out only by an Ingersoll Rand authorized service technician.

en

http://air.ingersollrand.com