*+ -/$*)

"(2($".4) -"$2 '$)"

For each wire feed speed, a corresponding voltage is

preprogrammed into the machine. The nominal pre-

programmed voltage is the best average voltage for a

given wire feed speed, but may be adjusted to prefer-

ence. When the wire feed speed changes, the Power

Wave automatically adjusts the voltage level corre-

spondingly to maintain similar arc characteristics

throughout the WFS range.

UltimArc™Control, adjusts the apparent inductance of

the wave shape. The UltimArc™Control adjustment is

similar to the “pinch” function in that it is inversely pro-

portional to inductance. Therefore, increasing

UltimArc™Control greater than 0.0 results in a crisper

arc (more spatter) while decreasing the

UltimArc™Control to less than 0.0 provides a softer

arc (less spatter).

+*2 -21 V

S

TART OPTIONS

END OPTIONS

SETUP

WELD MODE

UltimArc™ Control

L

ess

Deposition

More

D

eposition

Shorter

Arc

Longer

A

rc

+

+

AMPS

W

FS

VOLTS

TRIM

220

26.4

EFFECT / RANGE

PINCH EFFECT

(-10.0 to +10.0)

DESCRIPTION

-

E

FFECT

Preflow Time

Run-in WFS:

Start Procedure

D

ESCRIPTION

A

djusts the time

that shielding

gas

f

lows

a

fter the

t

rigger

i

s

p

ulled

and

prior to feeding.

Run-In sets the wire feed

speed from the time the trigger

is pulled until an arc is estab-

lished.

The Start Procedure controls

the WFS, Volts at a specified

time at the beginning of the

weld. During the start time, the

machine will ramp up or down

from the Start Procedure to the

preset Welding Procedure.

EFFECT

DESCRIPTION

Steel

Steel

Stainless

Stainless

Aluminum 4043

Aluminum 5356

E

LECTRODE AND GAS

CO

2

Ar(Mix)

Ar(Mix)

Ar/He/CO

2

Ar

Ar

W

IRE SIZE

0.030 0.035 0.045 0.052

---10 20 24

94 11 21 25

61 31 41 ---

63 33 43 ---

--- 148 71 ---

--- 151 75 ---

WELD MODE

UltimArc™ Control

END OPTIONS

S

TART OPTIONS

Pinch controls the arc characte-

-ristics when short-arc welding.

STEEL .035"

CV CO2

10

Spot Timer

Adjust the time welding will

continue even if the trigger

is still pulled. This option

has no effect in 4-Step

Trigger Mode.

Crater Procedure

Crater Procedure controls the

WFS and Volts for a specified

time at the end of the weld

after the trigger is released.

During the Crater time, the

machine will ramp up or down

from the Weld Procedure to

the Crater Procedure.

Burnback:

The burnback time is the

amount of time that the weld

output continues after the wire

stops feeding. It prevents the

wire from sticking in the puddle

and prepares the end of the

wire for the next arc start.

Postflow Time

Adjusts the time that shielding

gas flows after the welding out-

put turns off.

S

TART OPTIONS

END OPTIONS

SETUP

WELD MODE

UltimArc™ Control

L

ess

Deposition

More

D

eposition

Shorter

Arc

Longer

A

rc

+

+

AMPS

W

FS

VOLTS

TRIM

220

26.4

EFFECT / RANGE

PINCH EFFECT

(-10.0 to +10.0)

DESCRIPTION

-

E

FFECT

Preflow Time

Run-in WFS:

Start Procedure

D

ESCRIPTION

A

djusts the time

that shielding

gas

f

lows

a

fter the

t

rigger

i

s

p

ulled

and

prior to feeding.

Run-In sets the wire feed

speed from the time the trigger

is pulled until an arc is estab-

lished.

The Start Procedure controls

the WFS, Volts at a specified

time at the beginning of the

weld. During the start time, the

machine will ramp up or down

from the Start Procedure to the

preset Welding Procedure.

EFFECT

DESCRIPTION

Steel

Steel

Stainless

Stainless

Aluminum 4043

Aluminum 5356

E

LECTRODE AND GAS

CO

2

Ar(Mix)

Ar(Mix)

Ar/He/CO

2

Ar

Ar

W

IRE SIZE

0.030 0.035 0.045 0.052

--- 10 20 24

94 11 21 25

61 31 41 ---

63 33 43 ---

--- 148 71 ---

--- 151 75 ---

WELD MODE

UltimArc™ Control

END OPTIONS

S

TART OPTIONS

Pinch controls the arc characte-

-ristics when short-arc welding.

STEEL .035"

CV CO2

10

Spot Timer

Adjust the time welding will

continue even if the trigger

is still pulled. This option

has no effect in 4-Step

Trigger Mode.

Crater Procedure

Crater Procedure controls the

WFS and Volts for a specified

time at the end of the weld

after the trigger is released.

During the Crater time, the

machine will ramp up or down

from the Weld Procedure to

the Crater Procedure.

Burnback:

The burnback time is the

amount of time that the weld

output continues after the wire

stops feeding. It prevents the

wire from sticking in the puddle

and prepares the end of the

wire for the next arc start.

Postflow Time

Adjusts the time that shielding

gas flows after the welding out-

put turns off.

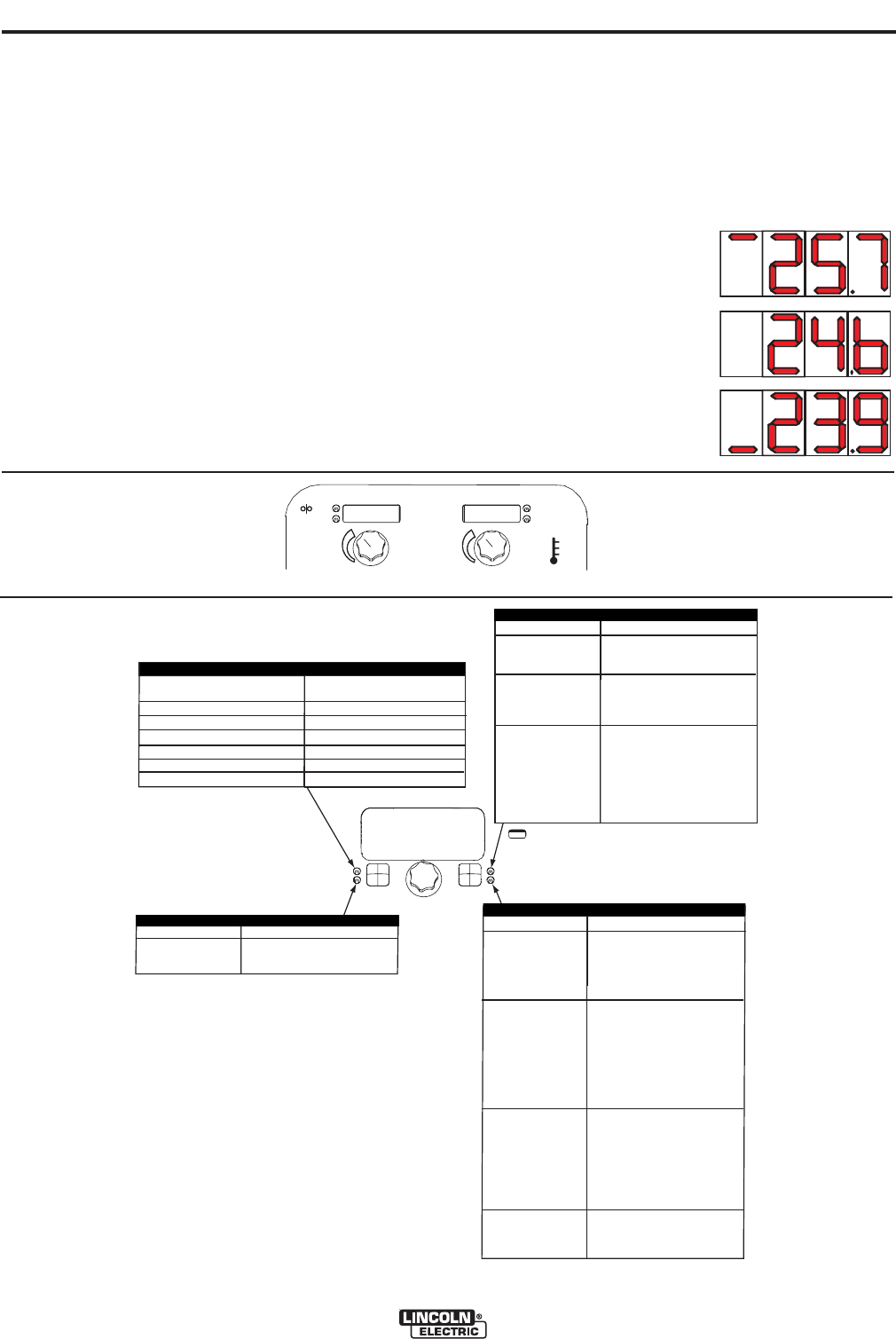

.OD;H=?91 programs feature an ideal voltage best

suited for most procedures. Use this voltage as a

starting point and adjust if needed for personal prefer-

ences.

When the voltage knob is rotated, the display will

show an upper or lower bar indicating if the voltage is

above or below the ideal voltage.

• Preset voltage above ideal

voltage. (upper bar displayed)

• Preset voltage at ideal

voltage. (no bar displayed)

• Preset voltage below ideal

voltage. (lower bar displayed)

.$*+ -/$*)

*)/-*'*+/$*).