*+ -/$*)

+*2 -21 V

'0($)0("(2++0'. ($"

)"(2+++0'. *)+0'.

2 '$)"

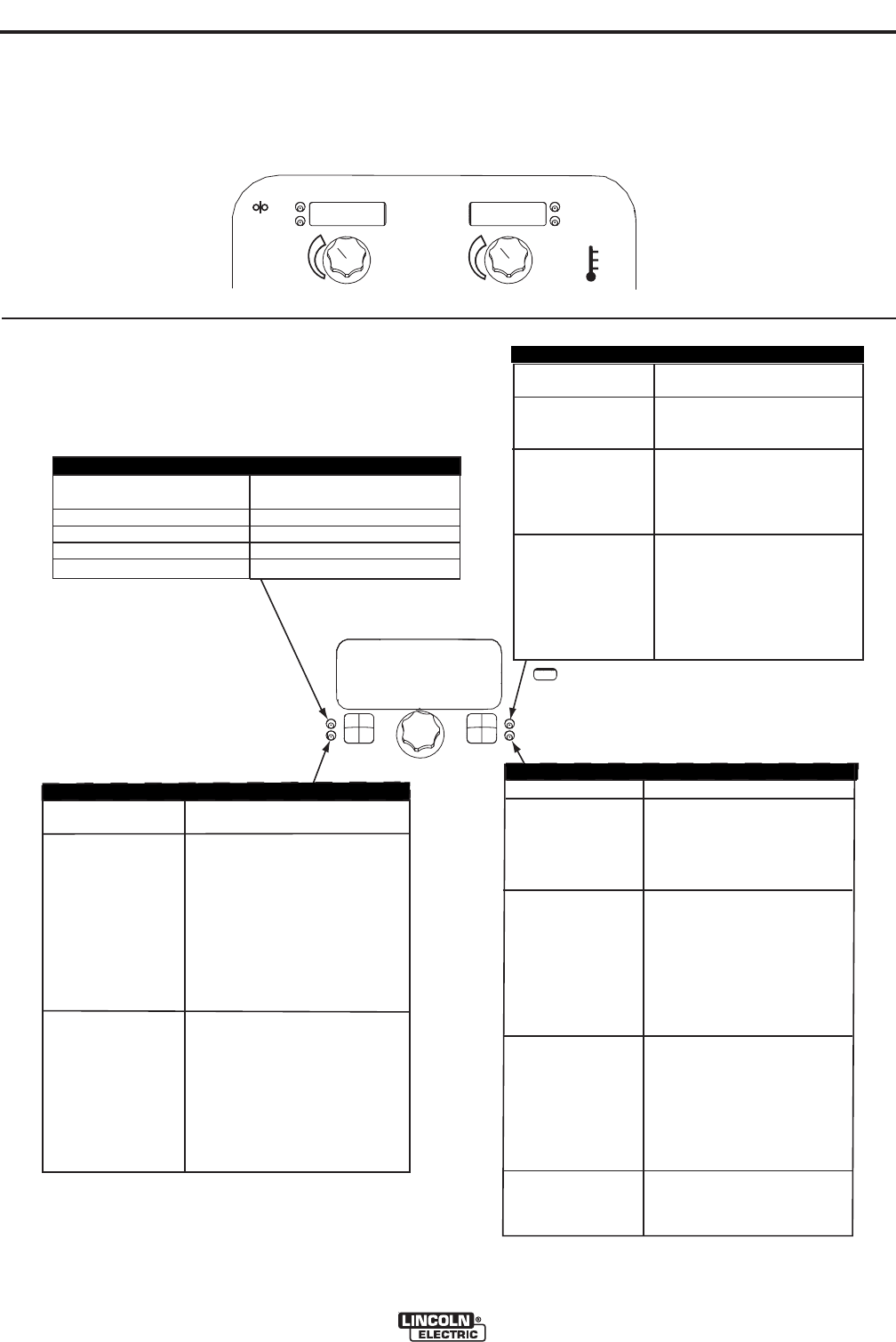

START OPTIONS

E

ND OPTIONS

SETUP

WELD MODE

UltimArc™ Control

Less

Deposition

More

Deposition

Shorter

Arc

Longer

Arc

+

+

AMPS

WFS

VOLTS

TRIM

220

1.06

72

EFFECT / RANGE

PULSE

PULSE-ON-PULSE

FREQUENCY:

FREQ.MODULATION

(Low)-10.0 to

(High)+10.0

(Low)-10.0 to

(High)+10.0

DESCRIPTION

For Pulse -On-Pulse modes,

Arc controls changes the frequ-

ency modulation. The freque-

-ncy modulation controls the

spacing of the ripples in the

weld. Use low values for slow

travel speeds and wide welds,

and high values for fast travel

speeds and narrower welds.

For Pulse

modes, Arc Control

changes the pulsing frequency.

When the frequency changes,

the Power Wave system auto-

matically adjusts the back-

ground current to maintain a

similar heat input into the weld.

Low frequencies give more con-

trol over the puddle and high

frequencies minimize spatter.

EFFECT

Postflow Time

RUN-INWFS:

.

Start Procedure

DESCRIPTION

Adjusts the time that shielding

gas

flows

after

the trigger is

pulled

and

prior to feeding wire.

Run-in sets the wire feed

speed from the time the trigger

is pulled until an arc is estab-

lished.

The Start Procedure controls

the WFS. Trim at a specified

time at the beginning of the

weld. During the start time, the

machine will ramp up or down

from the Start Procedure to the

preset Welding Procedure.

EFFECT

FUNCTION

ELECTRODE AND GAS

ALUMINUM 4043

ALUMINUM 4043

ALUMINUM 5356

ALUMINUM 5356

Ar

Ar

Ar

Ar

WIRE SIZE

0.035 3/64 1/16

149 72 74

98 99 100

152 76 78

101 102 103

WELD MODES

START OPTIONS

END OPTIONS

UltimArc™ Control

Aluminum 3/64"

Pulse 4043 Ar

Spot Timer

Adjust the time welding will

continue even if the trigger

is still pulled. This option

has no effect in 4-Step

Trigger Mode.

Crater Procedure

Crater Procedure controls the

WFS and Volts for a specified

time at the end of the weld

after the trigger is released.

During the Crater time, the

machine will ramp up or down

from the Weld Procedure to

the Crater Procedure.

Burnback:

The burnback time is the

amount of time that the weld

output continues after the wire

stops feeding. It prevents the

wire from sticking in the puddle

and prepares the end of the

wire for the next arc start.

Postflow Time

Adjusts the time that shielding

gas flows after the welding out-

put turns off.

START OPTIONS

E

ND OPTIONS

SETUP

WELD MODE

UltimArc™ Control

Less

Deposition

More

Deposition

Shorter

Arc

Longer

Arc

+

+

AMPS

WFS

VOLTS

TRIM

220

1.06

72

EFFECT / RANGE

PULSE

PULSE-ON-PULSE

FREQUENCY:

FREQ.MODULATION

(Low)-10.0 to

(High)+10.0

(Low)-10.0 to

(High)+10.0

DESCRIPTION

For Pulse -On-Pulse modes,

Arc controls changes the frequ-

ency modulation. The freque-

-ncy modulation controls the

spacing of the ripples in the

weld. Use low values for slow

travel speeds and wide welds,

and high values for fast travel

speeds and narrower welds.

For Pulse

modes, Arc Control

changes the pulsing frequency.

When the frequency changes,

the Power Wave system auto-

matically adjusts the back-

ground current to maintain a

similar heat input into the weld.

Low frequencies give more con-

trol over the puddle and high

frequencies minimize spatter.

EFFECT

Postflow Time

RUN-IN WFS:

.

Start Procedure

DESCRIPTION

Adjusts the time that shielding

gas

flows

after

the trigger is

pulled

and

prior to feeding wire.

Run-in sets the wire feed

speed from the time the trigger

is pulled until an arc is estab-

lished.

The Start Procedure controls

the WFS. Trim at a specified

time at the beginning of the

weld. During the start time, the

machine will ramp up or down

from the Start Procedure to the

preset Welding Procedure.

EFFECT

FUNCTION

ELECTRODE AND GAS

ALUMINUM 4043

ALUMINUM 4043

ALUMINUM 5356

ALUMINUM 5356

Ar

Ar

Ar

Ar

WIRE SIZE

0.035 3/64 1/16

149 72 74

98 99 100

152 76 78

101 102 103

WELD MODES

START OPTIONS

END OPTIONS

UltimArc™ Control

Aluminum 3/64"

Pulse 4043 Ar

Spot Timer

Adjust the time welding will

continue even if the trigger

is still pulled. This option

has no effect in 4-Step

Trigger Mode.

Crater Procedure

Crater Procedure controls the

WFS and Volts for a specified

time at the end of the weld

after the trigger is released.

During the Crater time, the

machine will ramp up or down

from the Weld Procedure to

the Crater Procedure.

Burnback:

The burnback time is the

amount of time that the weld

output continues after the wire

stops feeding. It prevents the

wire from sticking in the puddle

and prepares the end of the

wire for the next arc start.

Postflow Time

Adjusts the time that shielding

gas flows after the welding out-

put turns off.

.$*+ -/$*)

*)/-*'*+/$*).