Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

B-13

OPERATION

B-13

POWER-ARC 4000

The Power-Arc 4000 has a voltage output of up to 62

volts which can shock.

The electric arc is made between the work and the tip

end of a small metal wire, the electrode, which is

clamped in a holder that is held by the welder. A gap

is made in the welding circuit by holding the tip of the

electrode 1/16 - 1/8” (1.6-3.2mm) away from the work

or base metal being welded. The electric arc is

established in this gap and is held and moved along

the joint to be welded, melting the metal as it is

moved.

Arc welding is a manual skill requiring a steady hand,

good physical condition, and good eyesight. The

operator controls the welding arc and, therefore, the

quality of the weld made.

What Happens in the Arc?

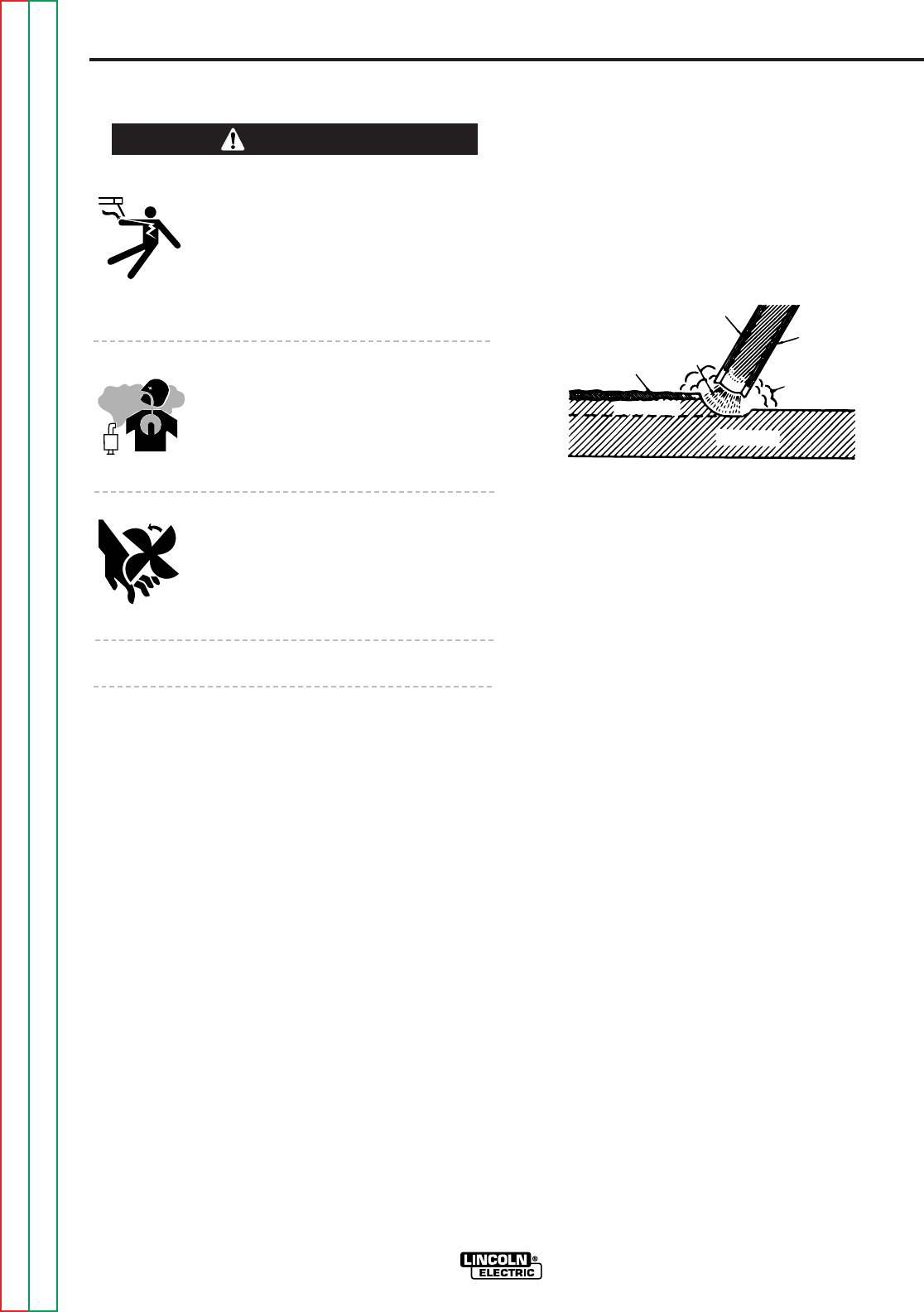

Figure 4 illustrates the action that takes place in the

electric arc. It closely resembles what is actually

seen during welding.

The “arc stream” is seen in the middle of the picture.

This is the electric arc created by the electric current

flowing through the space between the end of the

electrode and the work. The temperature of this arc

is about 6000°F (3316°C) which is more than enough

to melt metal. The arc is very bright, as well as hot,

and cannot be looked at with the naked eye without

risking painful and possibly permanent injury. A very

dark lens, specifically designed for arc welding must

be used with the handshield or headshield whenever

viewing the arc.

The arc melts the base metal and actually digs into it,

much like water through a garden hose nozzle digs

into the earth. The molten metal forms a pool or

crater and tends to flow away from the arc. As it

moves away from the arc, it cools and solidifies. Slag

forms on top of the weld to protect it during cooling.

The function of the covered electrode is much more

than simply to carry current to the arc. The electrode

is composed of a core metal wire around which has

been extruded and baked a chemical covering. The

core wire melts into the arc and tiny droplets of

molten metal shoot across the arc into the molten

pool. The electrode provides additional filler metal for

the joint to fill the groove or gap between the two

pieces of the base metal. The covering also melts or

burns in the arc. It has several functions. It makes

the arc steadier, provides a shield of smoke-like gas

around the arc to keep oxygen and nitrogen in the air

away from the molten metal, and provides a flux for

the molten pool. The flux picks up impurities and

forms a protective slag. The principle differences

between the various types of electrodes are in their

coatings. By varying the coating, it is possible to

greatly alter the operating characteristics of elec-

trodes. By understanding the differences in the vari-

ous coatings, you will gain a better understanding of

selecting the best electrode for the job you have at

hand. In selecting an electrode, you should consider:

1. The type of deposit you want, e.g., mild steel,

stainless, low alloy, hardfacing.

2. The thickness of the plate you want to weld.

3. The position it must be welded in (downhand,

out-of-position).

4. The surface condition of the metal to be welded.

5. Your ability to handle and obtain the desired

electrode.

Four simple manipulations are of prime importance.

Without complete mastery of these four, further

attempts at welding are futile. With complete

mastery of the four, welding will be easy.

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts

or electrode with skin or wet cloth-

ing.

• Insulate yourself from work and

ground.

• Always wear dry insulating gloves.

WARNING

ENGINE EXHAUST can kill.

• Use in open, well ventilated areas

or vent exhaust outside.

• Do not stack anything on or near

the engine.

MOVING PARTS can injure.

• Do not operate with doors open or

guards off.

• Stop engine before servicing.

• Keep away from moving parts.

Only qualified personnel should install, use, or

service this equipment.

Covering

Electrode

Shielding Gases

Arc

Solidified Slag

Weld Metal

Base Metal

FIGURE 4. -The welding arc.