F-34

TROUBLESHOOTING & REPAIR

F-34

POWER-ARC 4000

6. Install the bottom two end bracket thru-

bolts.

Note: The flat washer goes on the top right

hand thru-bolt for the green ground wire.

7. Tap the end bracket with the mallet as nec-

essary to position it. Tighten the bolts to

4.5 - 5.5 ft lbs. Alternate tightening in order

to pull the assembly together evenly. As

you tighten, look through the brush hous-

ing access door and watch the bearing to

judge end bracket movement and align-

ment.

8. Check the rotor-stator air gap with the long

.010 feeler gauge. The measurement is

taken through the brush holder access

door; see Figure F12. Turn the engine with

the recoil starter rope slightly so that the

rotor “iron” is up to take the measurement.

(The rotor has two flat sides, which are not

measured for air gap.) Slide in the gauge.

Then rotate the shaft 180 degrees and

measure again. If the gauge does not

clear, loosen the four end bracket thru-

bolts, reposition the end bracket, retighten

the bolts, and recheck the air gap. Repeat

until the proper .010 minimum air gap is

achieved.

9. Tighten the end bracket support nuts and

lock washers. Remove the 2 X 4 engine

support.

10. Reinstall the brush holder assembly. Refer

to the topic “BRUSH REMOVAL AND

REPLACEMENT” in this section of the

manual.

11. Slide the control box back into place. Pull

the stator and ground wire up through.

12. Remove the control panel (2 screws) and

reconnect the output terminal leads (W1,

W2). Install a new cable tie to hold the

leads together. Reconnect the stator

wire/harness molex coupling. Install the 6

screws that hold the control panel to the

box.

13. Reconnect Lead #202C.

14. Lift the control box and screw in the rubber

mountings. Set the control box onto the

mountings.

15. Install the front left hand washer and nut

that anchors the control box to the stator

frame. Position the reactor and install the

remaining washers and nuts.

16. Check all terminal connections for clear-

ance, grounding, and tightness.

17. Replace the top cover to the control box

and tighten the 4 nuts.

18. Conduct the “RETEST AFTER REPAIR”

procedure, the following topic in this sec-

tion of the manual.

STATOR/ROTOR REMOVAL AND REPLACEMENT (continued)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

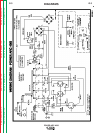

FIGURE F.12 - CHECKING ROTOR-STATOR AIR GAP

ROTOR

STATOR

FEELER GAUGE