Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

GENERAL DESCRIPTION

The Power MIG 300 is a complete semiautomatic,

multi-process DC arc welding machine offering CV and

CC DC welding. It is rated for 300 amps, 32 volts, at

60% duty cycle. The standard machine is equipped to

weld CC Stick, CC-GTAW, CV-FCAW, and synergic

and non-synergic CV GMAW/GMAW-P, Pulse-on-

Pulse, and Power Mode welding processes.

The digital microcomputer based control system allows

easy and accurate adjustment of weld parameters

through the multi-process panel located on the front of

the machine. The Power MIG 300 is equipped with a

6-pin connector for a foot amptrol or remotes and a 7-

pin connector to allow operation of a spool gun or a

push-pull gun for feeding aluminum wires.

THEORY OF OPERATION

E-2 E-2

POWER MIG 300

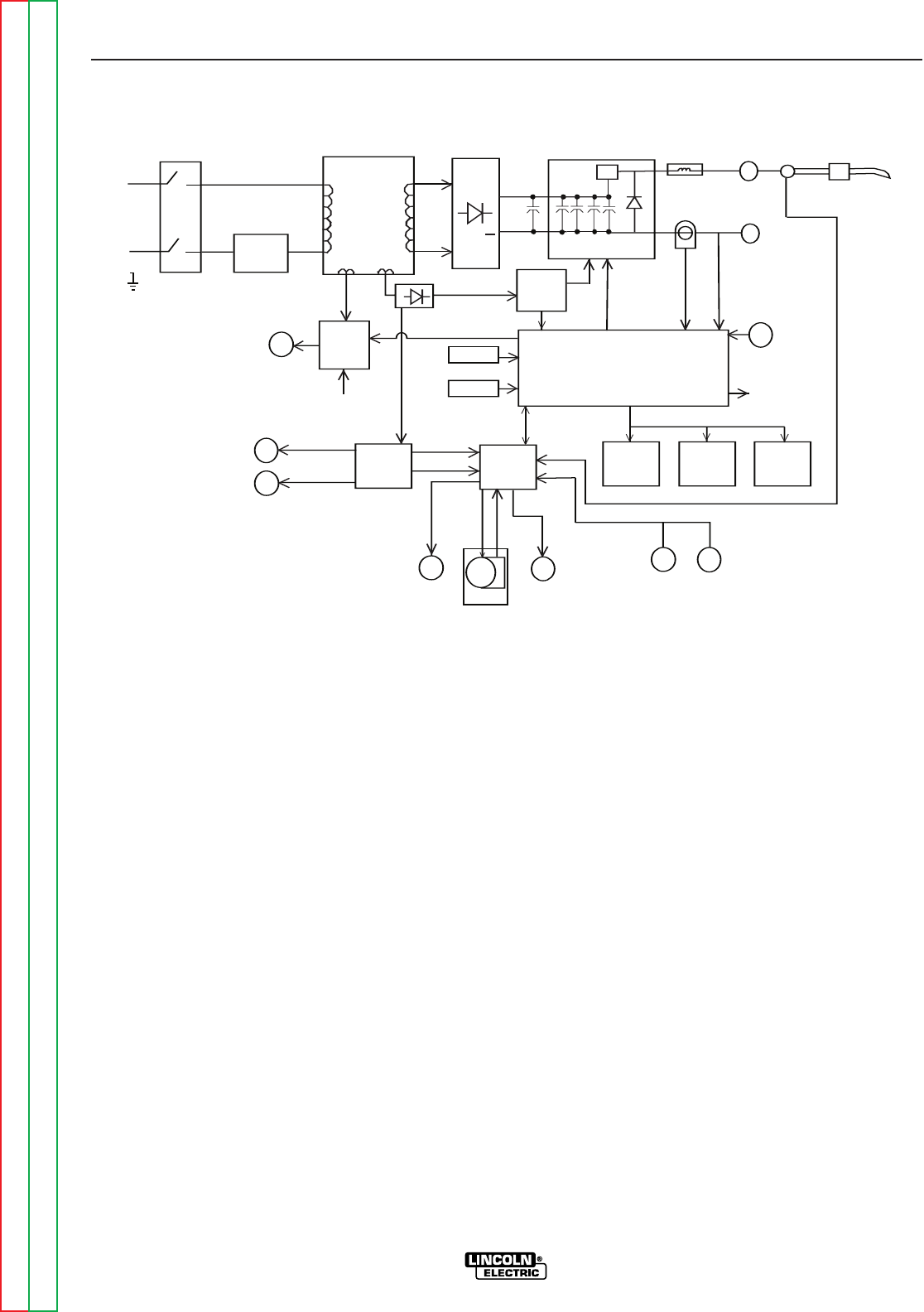

FIGURE E.2 –

INPUT VOLTAGE AND MAIN TRANSFORMER

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.

IGBT

+

LINE

SWITCH

RECONNECT

PANEL

MAIN

TRANSFORMER

RELAY

SPOOL

GUN

BOARD

FEEDER

BOARD

MSP

BOARD

ENCODER

BOARD

DISPLAY

BOARD

RS232

CONNECTOR

WELD CONTROL BOARD

SPOOL GUN

PUSH-PULL

SWITCH

WIRE DRIVE

MOTOR

OUTPUT

RECTIFIER

CHOPPER

ASSEMBLY

OUTPUT

CHOKE

CURRENT

TRANSDUCER

GUN

POS

OUTPUT

TERMINAL

NEG

OUTPUT

TERMINAL

POWER

BOARD

DIODE CONTROL

RECTIFIER

FAN

MOTOR

FOOT AMPTROL OR REMOTE (6-PIN AMPHENOL)

SPOOL GUN OR PUSH-PULL GUN (7-PIN AMPHENOL)

GAS

SOLENOID

SEC

THERMOSTATS

_

+

115

VAC

30

VAC

60

VAC

80

VAC

40 VDC

40

VDC

40 VDC

24 VDC

20 VDC

PWM

SIGNALS

+15/-15/+5 VDC

SHIELDED

CABLE

GUN TRIGGER AND THUMB SWITCH

SHIELDED CABLE AND SPI COMMUNICATIONS

ARCLINK

+5 VDC

CURRENT

FEEDBACK

VOLTAGE

FEEDBACK

FROM WELD

CONTROL BOARD

TO FAN RELAY

IGBT

DRIVE

T

A

C

H

CHOPPER

(Below code 10900)

Mechanical Encoders

(Above code 10900)