TROUBLESHOOTING & REPAIR

F-55 F-55

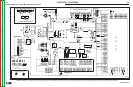

POWER MIG 300

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC

VOLTAGE & CURRENT CALIBRATION PROCEDURE (continued)

CALIBRATION CHECK

(CODES 10952 AND UP)

The calibration of the Power Mig 300 can be

checked using a resistive load bank with the

Power Mig 300 in mode 200. Mode 200 is a con-

stant current test mode.

1. Toggle and hold the mode select switch in the

up position.

2. Turn on the Power Mig 300.

3. Once the display reads “Pres Spin” release

the mode select switch. Rotate the output

knob until the display reads “ALL nodE”.

4. Toggle the Mode Select switch once and wait

for the machine to reset, then toggle the

MODE SET switch until the MSPlll panel

reads 200. Disengage the idler arm on the

wire drive so no wire will feed.

5. With the machine in mode 200 apply a resis-

tive to the welding output terminals (approx.

.106 ohms) set the machine output to 250

amps and enable the weld terminals by

pressing the trigger switch.

6. Using the test meters note the output voltage

and current.

7. The Power Mig 300 voltmeter must match the

test meter reading to within +/- 1 volt.

8. The Power Mig 300 ammeter must match the

test meter within +/- 5 amps.

9. If the volt meter does not meet the specifica-

tion then proceed to the Voltage Calibration

Procedure.

10. If the ammeter does not meet the specifica-

tion then proceed to the Current Calibration

Procedure.

NOTE: Before attempting to calibrate the voltage

or current setting of the Power Mig, be

sure to read the entire voltage or current

calibration procedure. If the steps are not

completed quickly, the machine will auto-

matically leave the calibration mode with-

out changing the calibration settings. The

voltage and current calibration settings of

the Power Mig are completely indepen-

dent of each other. Adjusting one will not

affect the other.

VOLTAGE CALIBRATION

1. Connect the resistive load bank (approximate-

ly .106 ohms) and test voltmeter to the weld-

ing output terminals.

2. Toggle and hold in the mode select switch in

the up position.

3. Turn on the Power Mig 300.

4. Once the display reads “Pres Spin” release

the mode select switch. Rotate the output

knob until the display reads “vol cAL”.

5. Release the mode select switch once.

6. The left display will change to “VcAL” to indi-

cate that voltage calibration is in progress.

7. The right hand display will scroll the following

message: Adj rEnc SorEAL vol = 20V.

8. Adjust output control knob until the actual out-

put voltage reading on the test volt meter is 20

volts +/- .5 volts.