OPERATION

B-3 B-3

POWERARC® 5500

LIMITATIONS

• The POWERARC® 5500 is not recommended for

any processes besides those that are normally per-

formed using stick welding (SMAW) procedures.

• The POWERARC® 5500 is not recommended for

pipe thawing.

• During welding, generator power is limited to 100

watts, and output voltages can drop from 120 to 80

volts and 240 to 160 volts. Therefore, DO NOT

OPERATE ANY SENSITIVE ELECTRICAL EQUIP-

MENT WHILE YOU ARE WELDING.

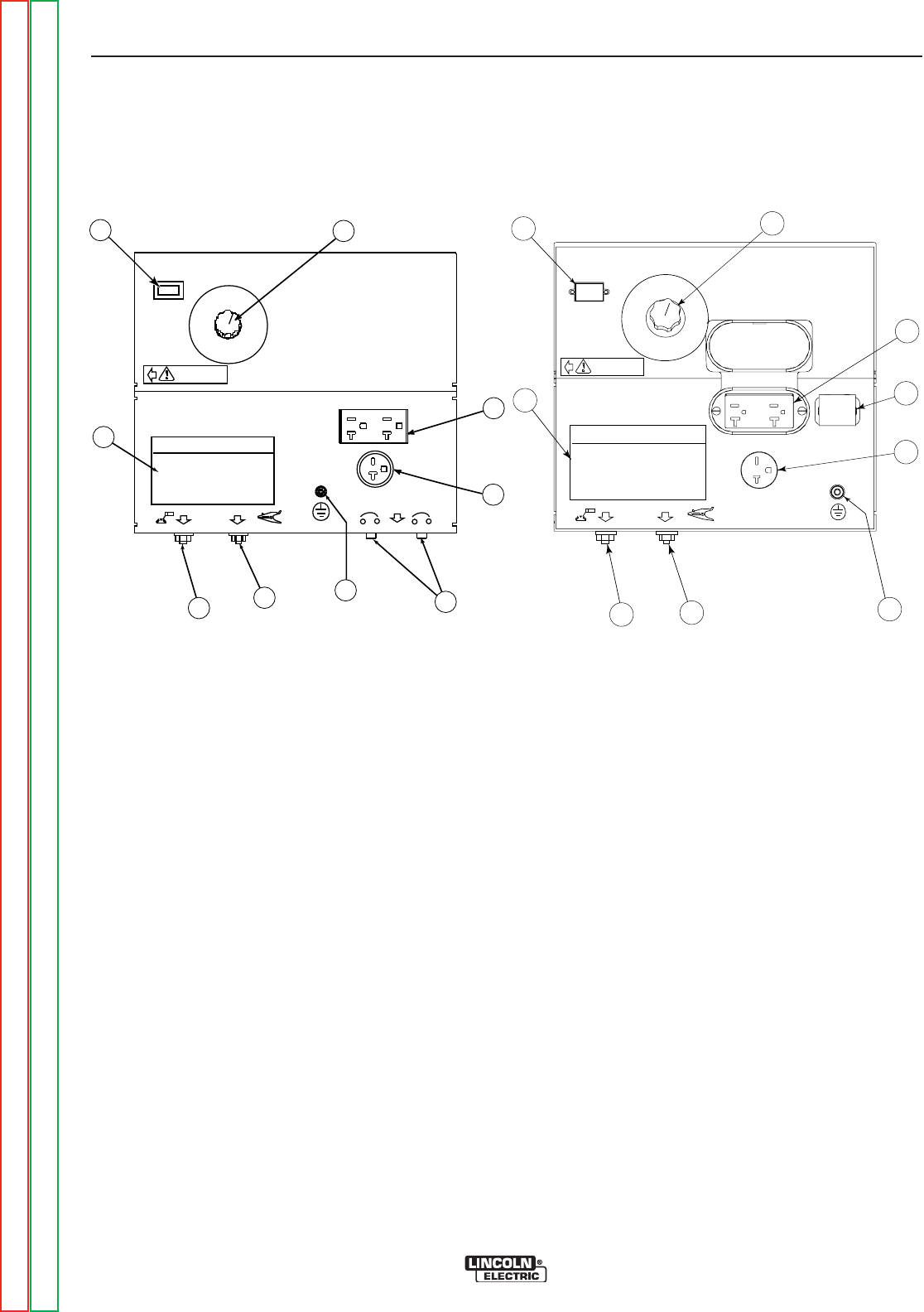

CONTROLS AND SETTINGS

All generator/welder controls are located on the

Output Control Panel. Gasoline engine controls are

mounted on the engine. See Figures B.1 and B.2 and

the explanations that follow.

GENERATOR/WELDER CONTROLS

See Figure B.1 for the location of the following fea-

tures:

1. CURRENT CONTROL DIAL: Adjusts continuous

current output. The amperages on the dial corre-

spond to the average amperages needed for spe-

cific Lincoln welding electrodes.

2. ELECTRODE SELECTION GUIDE: Provides rec-

ommended electrode type, size, and welder out-

put setting based on the thickness of the work.

3. WELD OUTPUT TERMINAL (TO ELECTRODE

HOLDER) WITH 1/2 - 13 FLANGE NUT: Pro vides

the connection point for either the electrode hold-

er or the work cable. (Because the POWERARC®

5500 is an AC output machine, either output ter-

minal can be used for either cable.)

POWER ARC POWER ARC 55550000

ELECTRODE SELECTION GUIDEELECTRODE SELECTION GUIDE

8080

9090

100100

7

070

AMPSAMPS

AMPSAMPS

AMPSAMPS

AMPSAMPS

WARNINGWARNING

AMPSAMPS

125125

GENERATORGENERATOR

8

7

6

5

3

1

2

4

9

8080

9

090

100100

7070

AMPSAMPS

AMPSAMPS

AMPSAMPS

AMPSAMPS

WARNINGWARNING

AMPSAMPS

125125

GENERATORGENERATOR

E

LECTRODE SELECTION GUIDEELECTRODE SELECTION GUIDE

7

6

8

3

5

1

4

POWER ARC 5500POWER ARC 5500

2

9

OUTPUT PANEL CONTROLS

Physical Location of Components may vary by Code No.

1. CURRENT CONTROL DIAL

2. ELECTRODE SELECTION GUIDE

3. WELD OUTPUT TERMINAL (TO ELECTRODE HOLDER) WITH

1/2 - 13 FLANGE NUT

4. WELD OUTPUT TERMINAL (TO WORK) WITH 1/2 - 13 FLANGE

NUT

5. GROUND STUD

6. 20 AMP CIRCUIT BREAKERS (2)

7. 20 AMP, 240 VOLT RECEPTACLE

8. 20 AMP, 120 VOLT DUPLEX RECEPTACLE

9. TACHOMETER / HOUR METER (CODE 11215 ONLY)

1. CURRENT CONTROL DIAL

2. ELECTRODE SELECTION GUIDE

3. WELD OUTPUT TERMINAL (TO ELECTRODE HOLDER) WITH

1/2 - 13 FLANGE NUT

4. WELD OUTPUT TERMINAL (TO WORK) WITH 1/2 - 13 FLANGE

NUT

5. GROUND STUD

6. 20 AMP CIRCUIT BREAKER

7. 20 AMP, 240 VOLT RECEPTACLE

8. 20 AMP, 120 VOLT DUPLEX RECEPTACLE

9. TACHOMETER / HOUR METER (CODE 11404 ONLY)

FIGURE B.1 (For Codes 11182, 11187, 11215)

FIGURE B.2 (For Codes 11403, 11404)

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC