CAPACITOR AND/OR DIODE BRIDGE

REMOVAL AND REPLACEMENT PROCEDURE (continued)

TROUBLESHOOTING AND REPAIR

F-32 F-32

POWERARC® 5500

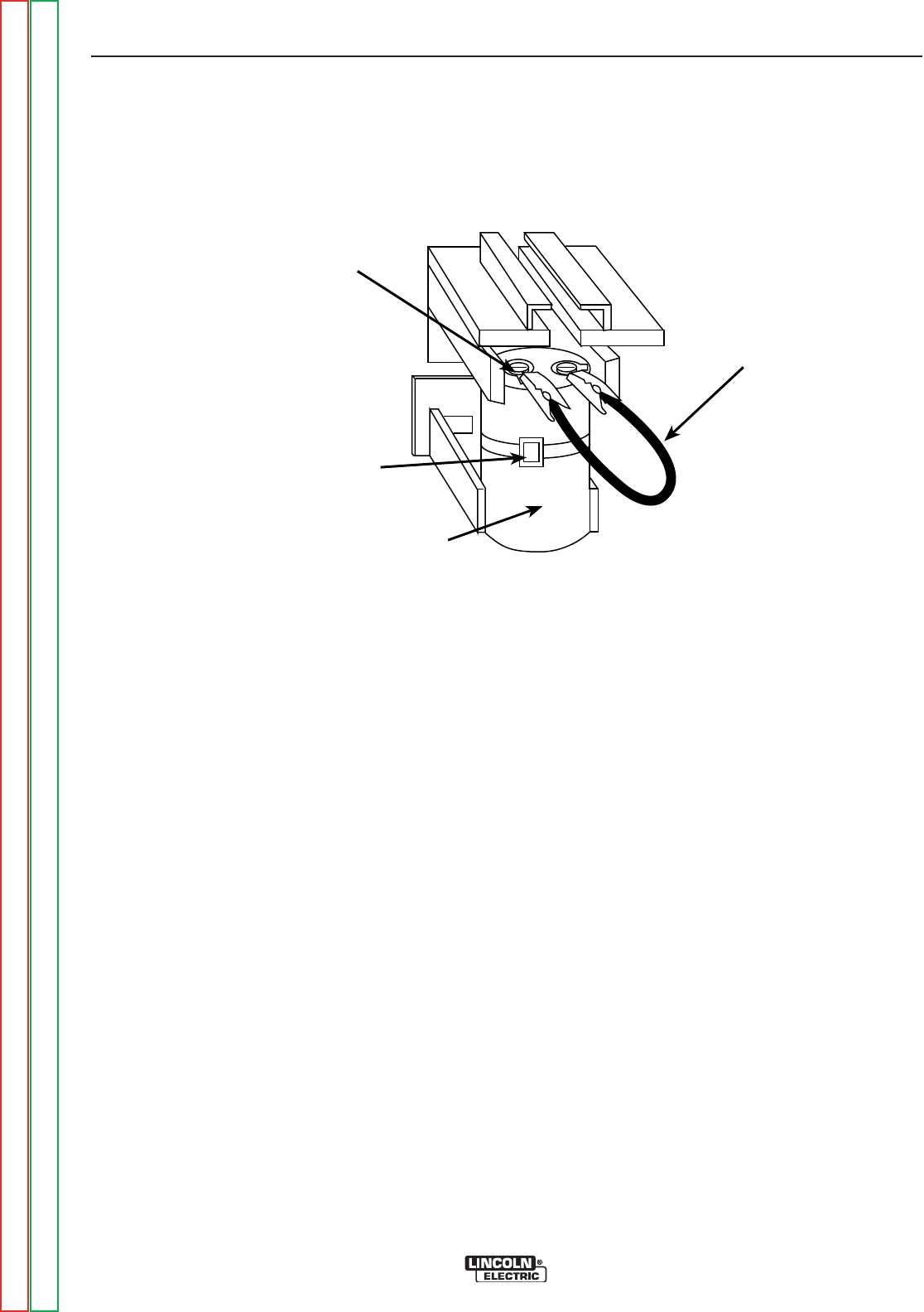

FIGURE F.9 - LOCATION AND DISCHARGING THE FIELD CAPACITOR

PROCEDURE - CAPACITOR

REMOVAL AND REPLACE-

MENT

1. Remove the engine spark plug wire.

2. With the 5/16” nut driver, remove the

8 sheet metal screws that hold the

top cover to the control box.

Remove the top cover.

3. With the 5/16” nut driver and wrench,

remove the 6 screws that hold the

control panel in place (2 in the front, 2

in the back, 2 in the bottom). Move

the panel aside as far as the leads will

allow.

4. Discharge the field capacitor by con-

necting the jumper wire clips on the

black and the red wire terminals on

the top of the capacitor. See Figure

F.9 for location. Leave the clips on

for at least 5 seconds, then remove.

5. The capacitor is mounted in a mold-

ed plastic holder. To remove it, pull

out on the top of the holder, then

slide it upward.

6. Snap the capacitor out of the assem-

bly.

7. Loosen the two screws on the top of

the capacitor. Leads 202A and 202

attach to the positive (+) terminal.

Leads 201 and 201A attach to the

negative (-) terminal.

8. To replace the capacitor, reattach the

leads to their respective terminals

(202A and 202 to positive (+); 201

and 201A to negative (-) and tighten

the screws securely. Snap the

capacitor back into the molded plas-

tic holder. Replace the control panel

and top cover of the control box and

tighten down the sheet metal screws

with the 5/16” nut driver.

201

201A

(-)

202

202A

(+)

Attachment for

Attachment for

Jumper

Capacitor

Cable Tie

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC