TROUBLESHOOTING AND REPAIR

F-36 F-36

POWERARC® 5500

STATOR/ROTOR

REMOVAL AND REPLACEMENT PROCEDURE (continued)

STATOR REMOVAL PROCEDURE

1. Remove engine spark plug wire to prevent

accidental kickback or starting.

2. With the 5/16” nut driver, remove the 8

sheet metal screws that hold the top cover

to the control box. Remove the top cover.

3. With the slot head screw driver, remove the

6 sheet metal screws that hold the control

panel to the control box - 2 on each side

and 2 on the bottom. You may need to use

the 5/16” end wrench on the engine side

because of limited clearance. Pull the

panel away from the control box.

4. Using the 7/16” wrench, remove the two

bolted reactor lead connections. See

Figure F.15.

5. Using the 1/2” socket wrench, remove the

two bolts and star washers mounting the

reactor to the stator assembly. See Figure

F.15.

6. Carefully remove the reactor.

7. Using the 1/2” socket wrench, remove the

two remaining bolts and star washers

securing the control box to the stator

assembly. See Figure F.16.

8. Using the 5/16” wrench, remove the five

sheet metal screws securing the control

box to the stator frame. CAUTION: One of

the screws secures the green grounding

lead to the frame of the machine. See

Figure F.16.

9. Unplug the large molex plug. See Figure

F.16.

10. Carefully remove the flashing lead #205

from diode D2 and clear lead from the con-

trol box. See Figure F.15.

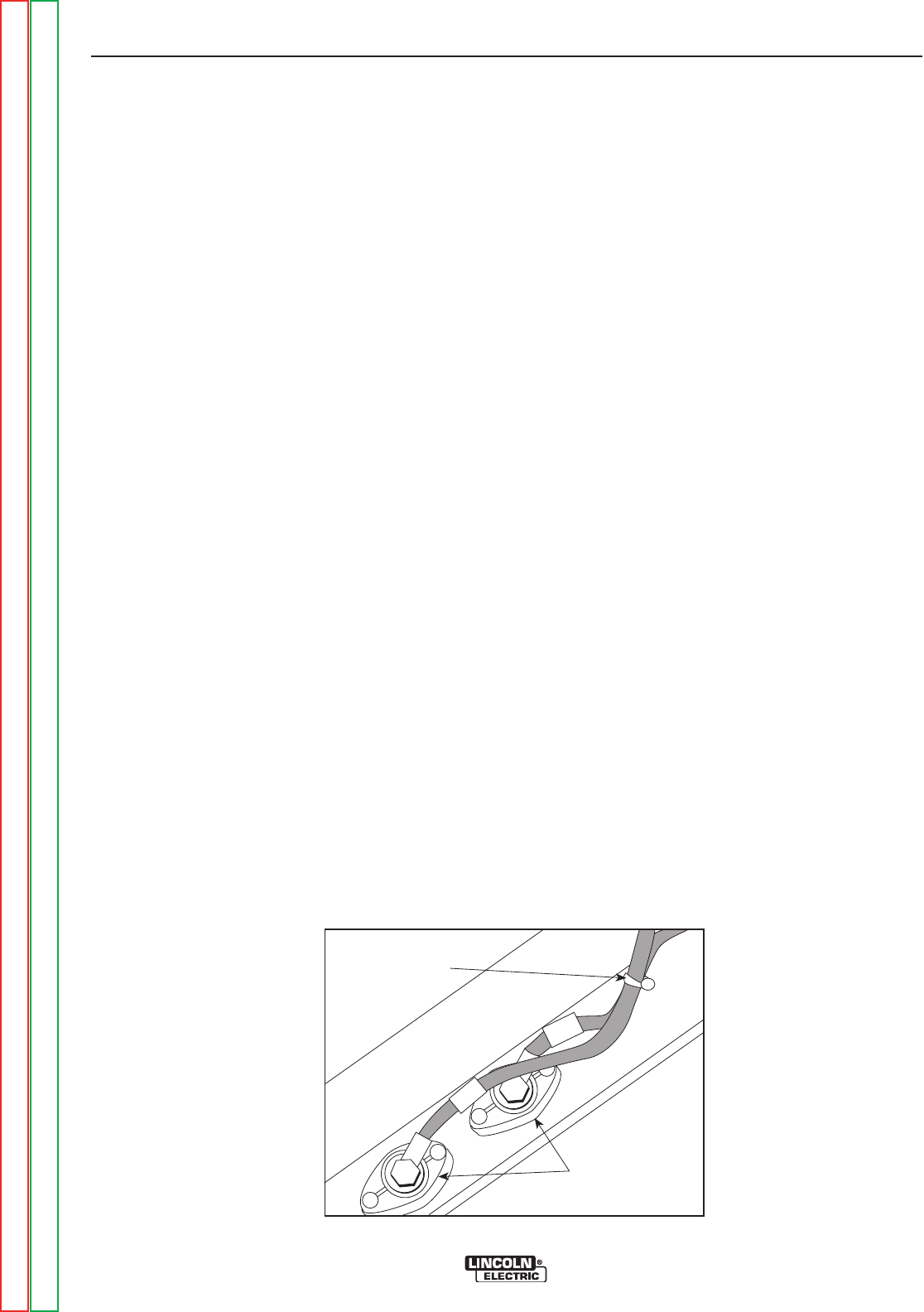

11. With the 9/16” open end wrench, remove

lead W2 from the output terminal. With

the diagonal cutters, cut the cable tie that

holds the two output leads together. Pull

lead W2 back out of the way. Screw the

bolt back into the output terminal hole

loosely for reassembly. See Figure F.11.

12. Remove the brush holder assembly. Open

the brush holder assembly cover.

Squeeze the 2 tabs and depress the cover

at the top with a screw driver or your fin-

gernail. The cover will drop open on its

bottom hinge. With the 1/4” nut driver,

remove the 2 screws that hold the brush

holder assembly in place. With the needle

nose pliers, gently remove the two leads

#201 and #202A. Note lead placement for

reassembly. Set the brush holder aside.

Pull the wires up into the control box.

13. Slide the control panel and box assembly

out of the machine cradle. Carefully pull

the wire leads down through the box as

you remove it.

FIGURE F.11 - OUTPUT LEAD LOCATION

OUTPUT

TERMINALS

W

1

W

2

TIE WRAP

Return to Section TOC Return to Section TOC Return to Section TOC Return to Section TOC

Return to Master TOC Return to Master TOC Return to Master TOC Return to Master TOC