OM-203 185 Page 52

SECTION 8 − MAINTENANCE & TROUBLESHOOTING

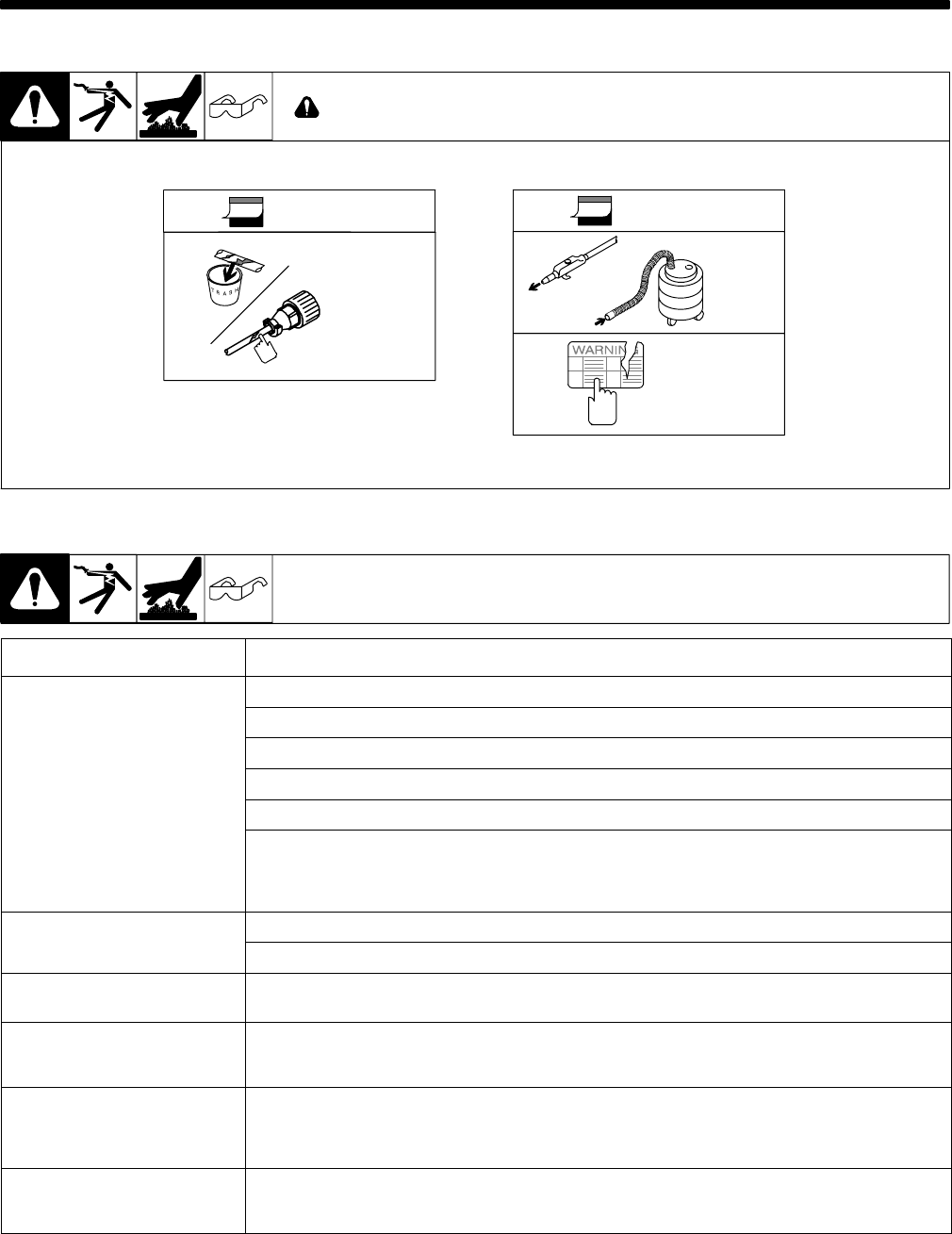

8-1. Routine Maintenance

Turn Off all power before maintaining.

3 Months

OR

Blow Out

Or

Vacuum

Inside

Replace

Unreadable

Labels

6 Months

Replace

Cracked

Parts

8-2. Troubleshooting

Trouble Remedy

IH/TS does not power up.

Be sure that power switch on rear of IH/TS is in the On position.

Check 115 volts ac at receptacle where IH/TS is plugged in.

Be sure that IH/TS is not plugged into a switched receptacle.

Check power source primary power for 3-phase, 400 or 460 volts ac (depending on model).

Replace building line fuse or reset circuit breaker.

For 5 kW PWHT cart, remove transformer cover on back of running gear, and check terminal strip jumpers

to verify they are set in the correct position.

For 25 kW PWHT system cart, remove transformer cover on back of running gear, and check for loose lead

connections.

Display flashes 5.br

Thermocouple open, connect thermocouple.

Two pin thermocouple plugged into ground (copper) pin, reconnect to the two silver pins.

Display flashes1dHi Workpiece actual temperature is more than 25 degrees over the target temperature. Wait for workpiece

temperature to drop or follow the recovery procedure in Section 6-3-5.

Power source contactor turns On

and Off at 25° over target

temperature.

Change Panel/Remote switch on power source to Remote position.

Conf 0 appears on the display. Press the up arrow to change the 0 to 2. Press scroll to enter the menu. Press page to Exit no and change

it to Exit YES, and the controller will reset automatically.

If display flashes no.io. Remove 2408 control from its housing by pressing locking tabs outward slightly on sides of control and pulling

control forward. Look for add−on PC card in back of controller, and check that white connector is fully inserted

into 2408 control. Reinstall 2408 control into housing being careful not to damage locking tabs on housing.