OM-880 Page 8

SB-112 332-A

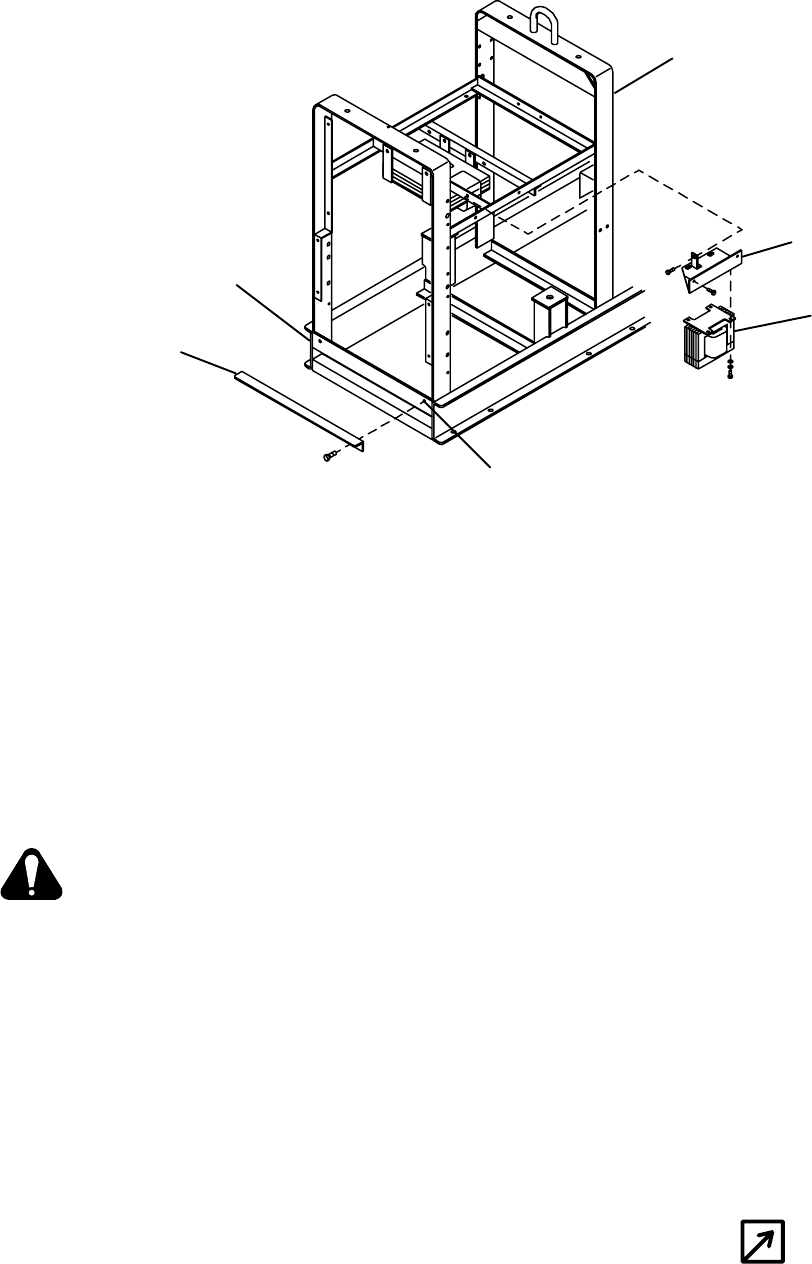

LEFT

FRONT

Welding

Generator Frame

Big 40 Diesel, Big 40G, And

Big 50 Diesel Transformer

Mounting Bracket

Transformer

T2

RIGHT

Use Switch Guard

As Template To

Mark Hole Locations

Switch Guard

(Angle Bracket)

Install Switch Guard Onto

Lower Front Portion Of

Base Just Below New

Lower Front Panel

Figure 3-5. Location For Switch Guard Installation

D. Switch Guard Installation (Figure 3-5)

IMPORTANT: Switch guard installation is only neces-

sary on welding generators without this bracket installed

from the factory.

1. Locate the supplied switch guard (angle bracket),

and using the guard as a template, mark the two

mounting hole locations onto lower front portion

of the welding generator base as shown in Figure

3-5.

CAUTION: METAL FILINGS AND/OR

TOOL CONTACT WITH INTERNAL COM-

PONENTS can damage unit.

• Cover internal components.

• Clean unit, and remove internal covering

material before resuming operation.

2. Drill 9/32 in. (7 mm) diameter hole at each

marked location.

3. Install and secure the switch guard with the two

supplied 5/16-18 x 3/4 in. self-forming screws.

E. Final Procedure

1. Reinstall weld output terminal bracket onto left

front upright.

IMPORTANT: To ease reinstalling of the weld output

terminal bracket, position cables 19 and 30 below the

bottom edge of the bracket so that the cables are routed

along the left side of the stator barrel. Also, check the

bimetal jumper bar connection at the rear of the weld

output terminal after reinstalling the bracket; tighten the

bimetal jumper bar securing hardware if necessary.

2. Affix supplied ELECTRODE label over NEGA-

TIVE designation for weld output terminal.

3. Affix supplied WORK label over POSITIVE des-

ignation for weld output terminal.

4. Connect weld cables to weld output terminals as

follows: Electrode holder cable to weld output

terminal labeled ELECTRODE, and work clamp

cable to weld output terminal labeled WORK.

IMPORTANT: Once weld cables are connected to the

unit, the Selector Switch position provides the desired

DC polarity or AC to the weld output terminals.

5. On all welding generator models except BIG 30A

DIESEL, reinstall components as follows:

a. Reinstall and secure top cover.

b. Reinstall and secure the air cleaner hose onto

the engine intake manifold.

6. On BIG 40 DIESEL, BIG 40G, and BIG 50 DIE-

SEL models: Reinstall and secure the muffler

onto the exhaust pipe.

7. Close and secure both side doors.

3-2. REMOTE-5 RECEPTACLE INFORMATION

AND CONNECTIONS (Figure 3-6 And 4-1)

REMOTE-5

The 5-socket REMOTE-5 receptacle RC3 provides a

junction point for connecting a Remote Contactor and/or

Amperage or Voltage Control to the control circuitry of