OM-880 Page 19

SC-112 013-A

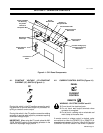

Voltage Control

Board PC4

Wiring Harness Plug

Standoff

Support (4)

Contactor Control

Board PC3

Wiring Harness Plug

Standoff Support (3)

Figure 6-1. Circuit Board Locations And Components

CAUTION: ELECTROSTATIC DISCHARGE

(ESD) can damage circuit boards.

• Put on properly grounded wrist strap

BEFORE handling circuit boards.

• Transport circuit boards in proper static-

shielding carriers or packages.

• Perform work only at a static-safe work area.

INCORRECT INSTALLATION or misaligned

plugs can damage circuit board.

• Be sure that plugs are properly installed and

aligned.

EXCESSIVE PRESSURE can break circuit

board.

• Use only minimal pressure and gentle move-

ment when disconnecting or connecting

board plugs and removing or installing board.

IMPORTANT: All directions, such as left or right, are

with respect to the serviceperson facing the front panel.

1. Open necessary side door as follows: left side for

Contactor Control board PC3, or right side for

Voltage Control board PC4.

2. Disconnect wiring harness plug from board re-

ceptacle (see Figure 6-1), and remove board

from standoff supports.

3. Reconnect wiring harness plug to new board re-

ceptacle; be sure plug snaps firmly in place.

4. Install and secure new board onto standoff sup-

ports on lower front panel.

5. Close side door.

6. Resume operation.

6-4. TUNGSTEN ELECTRODE (Table 6-2, And

Figures 6-2 And 6-3)

Use Table 6-2 to select the correct size and type tung-

sten electrode. Prepare the tungsten electrode using

the following guidelines. A properly prepared tungsten

electrode is essential in obtaining a satisfactory weld.

A. For AC or DC Electrode Positive Welding (Fig-

ure 6-2)

Ball the end of tungsten electrodes used for ac or dc

electrode positive welding before beginning the welding

operation. Weld amperage causes the tungsten elec-

trode to form the balled end. The diameter of the end

should not exceed the diameter of the tungsten elec-

trode by more than 1-1/2 times. For example, the end of

a 1/8 in. (3.2 mm) diameter tungsten electrode should

not exceed a 3/16 in. (4.8 mm) diameter end.