OM-880 Page 21

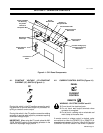

Stable Arc

Straight Ground

Flat

(The Dia. Of This

Flat Governs

Amperage Capacity)

Arc Wander

Point

Radial Ground

TUNGSTEN PREPARATION: IDEAL

TUNGSTEN PREPARATION: WRONG

S-0162

Figure 6-3. Tungsten Preparation

Shape tungsten electrodes on a fine grit, hard abrasive

wheel used only for tungsten shaping. Grind tungsten

electrodes so that grinding marks run lengthwise with

the electrode. These procedures reduce the possibility

of the tungsten electrode transferring foreign matter into

the weld and help reduce arc wander.

Grind the end of the tungsten electrode to a taper for a

distance of 2 to 2–1/2 electrode diameters in length. For

example, the ground surface for a 1/8 in. (3.2 mm) di-

ameter tungsten electrode should be 1/4 to 5/16 in. (6.4

to 8.0 mm) long.

For additional information, see your distributor for a

handbook on the Gas Tungsten Arc Welding (GTAW)

process.

6-5. TROUBLESHOOTING

WARNING: ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Stop engine, and disconnect negative (–) bat-

tery cable from battery before inspecting,

maintaining, or servicing.

MOVING PARTS can cause serious injury.

• Keep away from moving parts such as fans,

belts, and rotors.

HOT ENGINE PARTS can cause severe

burns.

• Wear protective gloves and clothing when

working on a hot engine.

MAGNETIC FIELDS FROM HIGH CUR-

RENTS can affect pacemaker operation.

• Wearers should consult with their doctor be-

fore going near arc welding, gouging, or spot

welding operations.

Troubleshooting of internal parts to be per-

formed only by qualified persons.

IMPORTANT: Before beginning any troubleshooting

procedures, check and be sure that all connections are

correct and secure and that all switches are in the proper

position.