OM-880 Page 17

5. If high frequency is desired, install and connect

the high frequency unit according the the equip-

ment Owner’s Manual.

6. Select and obtain proper tungsten electrode (see

Table 6-2).

7. Prepare tungsten electrode according to Section

6-4, and insert into torch.

8. Wear dry insulating gloves and clothing.

9. Connect work clamp to clean, bare metal at work-

piece.

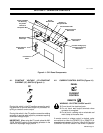

10. Rotate the AMPERE RANGES switch and AM-

PERAGE AND VOLTAGE ADJUSTMENT con-

trol to the desired position (see welding generator

Owner’s Manual).

11. Place the CV-2 CV/CC switch in the CC mode

(see Section 4-1).

12. Connect a Remote Contactor Control to the ap-

propriate CV-2 REMOTE-5 or REMOTE-14 re-

ceptacle, and place the OUTPUT/CONTACTOR

switch in the REMOTE position (see Sections

3-2, 3-3, and 4-3).

13. If remote amperage control is not used, place the

CV-2 CURRENT CONTROL switch in the

PANEL position. If remote amperage control is to

be used, place the CURRENT CONTROL switch

in the REMOTE position (see Section 4-2).

14. Place the AC/DC Selector switch in the desired

position (see Section 4-4).

WARNING: ELECTRIC SHOCK can kill.

• Do not use AC output in damp areas, if

movement is confined, or if there is a danger

of falling.

• Use AC output ONLY if required for the weld-

ing process.

• If AC output is required, use remote output

control.

• Read and follow Safety Precautions at be-

ginning of welding generator Owner’s Manu-

al.

15. Turn on the high frequency equipment, if applica-

ble.

16. Turn on shielding gas supply and water (if appli-

cable) at the source.

17. Start the engine as instructed in the welding gen-

erator Owners Manual.

18. Place the AUTO IDLE control switch in the OFF

position or the Engine Control switch in the RUN

position (see welding generator Owner’s Man-

ual).

IMPORTANT: Power requirements by CV-2 compo-

nents will cause the welding generator engine to operate

at weld rpm continuously in the CV mode if the AUTO

IDLE control switch is placed in the ON position or the

Engine Control switch is placed in the AUTO IDLE posi-

tion. Placing the AUTO IDLE control switch in the OFF

position or the Engine Control switch in the RUN posi-

tion will prevent mistaking unit operation as a malfunc-

tion in the Auto Idle circuitry.

19. Wear welding helmet with proper filter lens ac-

cording to ANSI Z49.1.

20. Begin welding.

5-4. SHUTTING DOWN

1. Stop welding.

2. Turn off or disconnect all auxiliary equipment.

3. Remove all weld and power loads from the unit.

4. Allow the engine to idle for a few minutes to per-

mit the internal engine temperature to equalize.

Increase the idling time if the engine has been op-

erating for an extended period or at full load.

5. Stop the engine.

6. Turn off the shielding gas and water/coolant sup-

ply if applicable.

WARNING: HIGH CONCENTRATION OF

SHIELDING GAS can harm health or kill.

• Shut off gas supply when not in use.