19

Maintenance Checklist

Note: See also the Maintenance section on

page 16.

Work area around machine marked off

clearly.

Non-skid floor strips in area where operator

normally stands.

Inspect entire machine for loose bolts, nuts,

screws. Tighten and replace as necessary.

Clean conveyor and drum areas, removing

sawdust and chips with compressed air or a

soft bristle brush. Remove gum and pitch

from metal areas with oven cleaner.

Lubricate chain and check tension.

Check belt condition - replace as needed.

Dress with paraffin. Check belt tension.

Check motor for loose wiring and sawdust

congestion.

Pulleys tight and in line.

Check bearings. Replace any bad or

suspect bearings immediately.

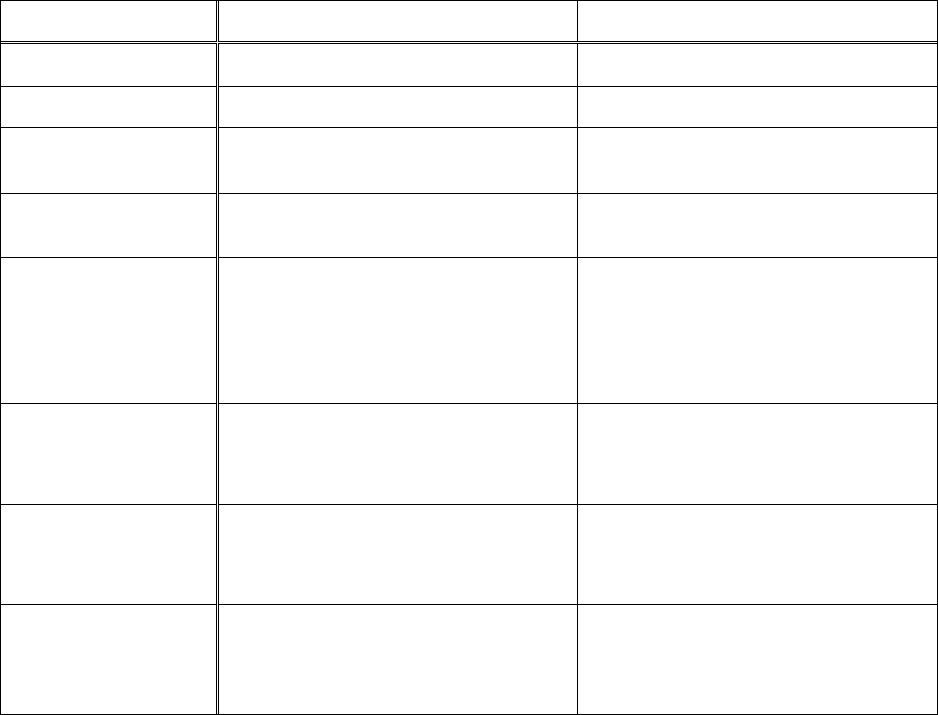

Troubleshooting

Performance Problems

Problem Possible Cause Solution

Abrasive belt glazes Wood is wet or gummy No cure. Use different stock

Work burns Wrong grit Use coarser grit for stock removal

Abrasive belt burns,

clogs quickly

Biting too deep Adjust for slight sanding action and

make repeated passes

Excessive abrasive

belt replacement

Biting too deep Reduce cut and make multiple passes

Sanding marks on

workpiece

Abrasive belt too coarse for finish

required

Sanding across the grain

Use proper grit for finish sanding

When surface sanding, use very fine

abrasive belt then finish by hand,

working in direction of grain.

Poor sanding quality Abrasive belts worn

Abrasive belts not tight on drum

Replace abrasive belts

Re-wrap and properly tighten

abrasive belts.

A slight taper across

the sanded face of

the workpiece

Height of rear drum has not been

adjusted evenly on both ends

Conveyor table not parallel to drums

Make drum setting equal both ends

Correct table parallelism

Conveyor table hard

to move, or tends to

bind on the

leadscrews

Leadscrews not greased

Table not parallel

Lubricate leadscrews

Correct table parallelism