18

This concludes the assembly section. Except for installing table boards, fence, and table clamps

the saw should be completely assembled. The next section deals with adjusting your saw to

remove any "looseness" in order to get accurate cuts.

Assembly

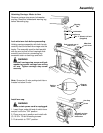

Remove saw blade.

1. Tighten carriage lock knob, located on

rightsideofarm.

2. Loosen guard clamp screw approximately

4 turns. Rotate dust elbow so opening is fac-

ing left.

3. Use one hand to lift the clear plastic

guard at the front of the saw.

4. Use the other hand to grasp the rear of

the guard (below the dust elbow).

5. Rotate the entire guard assembly forward

approximately 45°.

6. Remove the guard assembly.

7. Motor shaft has left hand threads. Hold

shaft wrench and rotate arbor wrench down

(clockwise).

8. Remove shaft nut, outer collar, saw

blade, and inner collar. Set aside and out of

the way.

Attach Table Supports

1. Set out:

- two table supports

- four 5/16" 18 x 3/4" long square head

screws

- four 11/32" x 7/8" x 1/16" flatwashers

-four5/16"lockwashers

- four 5/16" hex nuts

2. Attach supports to side frame, making

sure to use correct holes in table supports

and side frame: Use two screws per support

(insert screws through base and then sup-

port); on end of each screw put a flat

washer, lockwasher and nut then finger

tighten so table supports rest in lowest posi-

tion.

Pull down

to loosen

Blade

Rotation

Table

Support

Screws

Here

Nut

Lockwasher

Flatwasher

Front

Base

Square Head Screw

5/16 - 18 x 3/4"

Mount rails using

these holes

Table

Support